Clean production method of battery level lithium carbonate

A production method and technology of lithium carbonate, applied in lithium carbonate;/acid carbonate and other directions, can solve the problems of low product purity, long production cycle, cumbersome process, etc., and achieve simple process, low cost, The effect of strong process feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

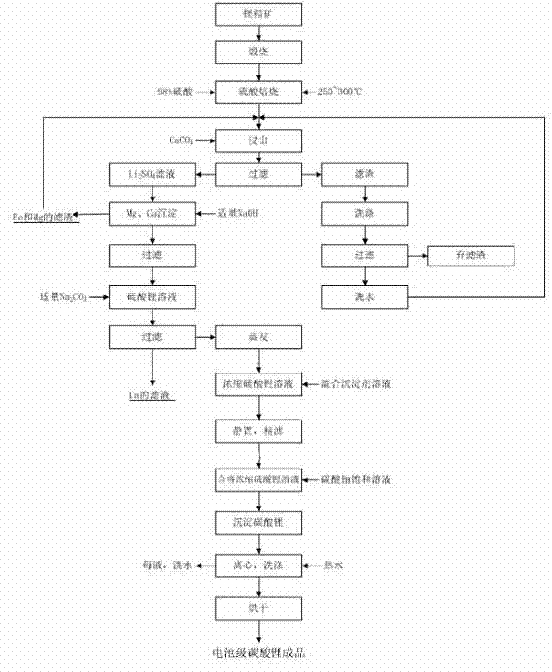

Method used

Image

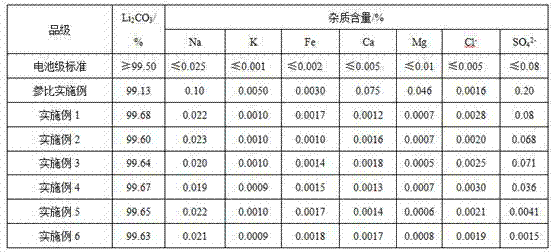

Examples

Embodiment 1

[0043] Embodiment 1 The clean production method of battery grade lithium carbonate of the present invention

[0044] The clean production method of battery grade lithium carbonate of the present invention comprises the steps:

[0045] (1) Preparation of β-spodumene lithium concentrate: Select 1000kg of enriched natural spodumene concentrate and place it in a rotary furnace, and control the temperature in the rotary furnace to roast at 1100°C for 5 hours to prepare β-spodumene Lithium concentrate;

[0046] (2) Lithium sulfate solution preparation: When the temperature of the rotary furnace is controlled at 95°C, the β-spodumene lithium concentrate is crushed and sieved to make ore powder, and an excess of 25% sulfuric acid solution is added to the ore powder to mix and then transferred to the rotary furnace Sinter at 270°C for 5 hours; pulverize the sintered ore powder and soak it with purified water to obtain a crude product solution, use calcium carbonate to neutralize exc...

Embodiment 2

[0050] Embodiment 2 Production method of battery grade lithium carbonate of the present invention

[0051] The clean production method of battery grade lithium carbonate of the present invention comprises the steps:

[0052] (1) Preparation of β-spodumene lithium concentrate: Select 1000kg of enriched natural spodumene concentrate and place it in a rotary furnace, and control the temperature in the rotary furnace to roast at 1150°C for 6 hours to prepare β-spodumene Lithium concentrate; under this condition, the α-spodumene in the ore is transformed into β-spodumene lithium concentrate.

[0053] (2) Lithium sulfate solution preparation: When the temperature of the rotary furnace is controlled at 100°C, the β-spodumene lithium concentrate is crushed and sieved to make ore powder, and an excess of 25% sulfuric acid solution is added to the ore powder to mix and then transferred to the rotary furnace Sinter at 250°C for 3 hours; pulverize the sintered ore powder and soak it wi...

Embodiment 3

[0057] Example 3 Production method of battery grade lithium carbonate of the present invention

[0058] The clean production method of battery grade lithium carbonate of the present invention comprises the steps:

[0059] (1) Preparation of β-spodumene lithium concentrate: Select 1000kg of enriched natural spodumene concentrate and place it in a rotary furnace, and control the temperature in the rotary furnace to roast at 1130°C for 6 hours to prepare β-spodumene Lithium concentrate;

[0060] (2) Lithium sulfate solution preparation: When the temperature of the rotary furnace is controlled at 110°C, the β-spodumene lithium concentrate is crushed and sieved to make ore powder, and an excess of 25% sulfuric acid solution is added to the ore powder to mix and then transferred to the rotary furnace Sinter at 300°C for 3.5 hours; pulverize the sintered ore powder and soak it with purified water to obtain a crude product solution, use calcium carbonate to neutralize excess sulfur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com