Method for extracting aluminum oxide by quickly heating fly ash

A technology of rapid heating and fly ash, applied in the direction of alumina/hydroxide, etc., can solve the problems of reactor wall adhesion, environmental protection impact, inability to fluidize, etc., achieve less equipment footprint and improve economic benefits , The effect of easy material temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

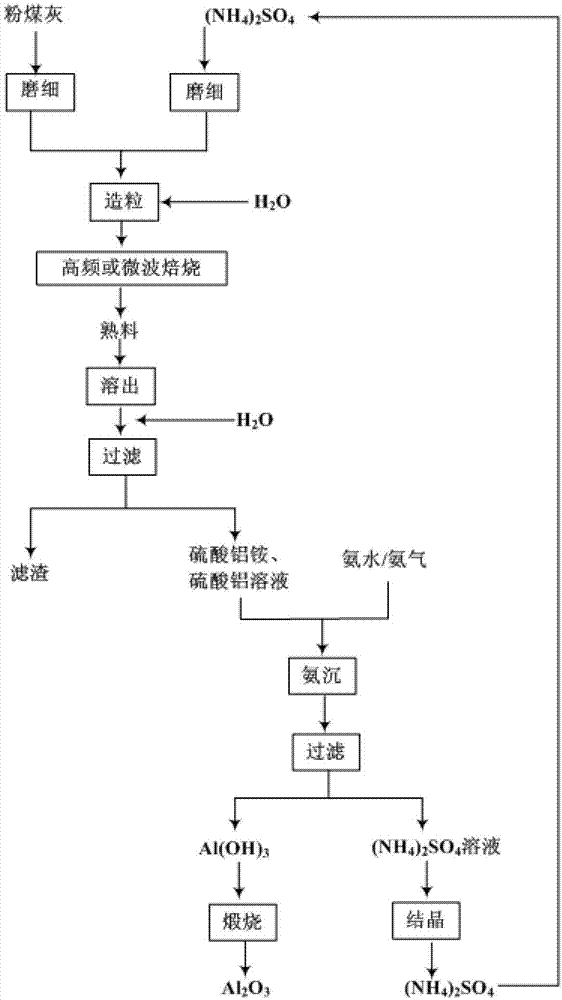

Image

Examples

Embodiment 1

[0032] Grind the fly ash containing 21% of alumina and 62% of silica to 100 meshes, mix the ingredients according to the molar ratio of ammonium sulfate and alumina in the fly ash 4:1, and mix them evenly in the uniformly mixed material Add 5% tap water, then granulate, the particle size is 5mm, enter the high-frequency or microwave device, and heat for 20min. The calcined clinker is added with deionized water whose mass is 3 times that of the clinker, dissolved at 80°C for 1.5h, filtered, and ammonia water is added to the filtrate to obtain aluminum hydroxide precipitation, washed and filtered, the aluminum hydroxide solid is roasted alumina product , The filtrate is evaporated and crystallized to obtain solid ammonium sulfate for recycling.

Embodiment 2

[0034] Grind the fly ash containing 25% of alumina and 60% of silica to 120 meshes, mix the ingredients according to the molar ratio of ammonium sulfate and alumina in the fly ash of 5:1, and mix them evenly in the uniformly mixed material Add 10% tap water, then granulate, the particle size is 10mm, enter the high-frequency or microwave device, and heat for 40min. The calcined clinker is added with deionized water whose mass is 4 times that of the clinker, dissolved at 85°C for 1 hour, filtered, and ammonia water is added to the filtrate to obtain aluminum hydroxide precipitation, washed and filtered, the aluminum hydroxide solid is calcined alumina product, The filtrate is evaporated and crystallized to obtain solid ammonium sulfate for recycling.

Embodiment 3

[0036] Grind the fly ash containing 30% of alumina and 45% of silica to 200 meshes, mix the ingredients according to the molar ratio of ammonium sulfate and alumina in the fly ash 6:1, and mix them evenly in the uniformly mixed material Add 15% tap water, then granulate, the particle size is 15mm, enter the high-frequency or microwave device, and heat for 60min. The calcined clinker is added with deionized water whose mass is 5 times that of the clinker, dissolved at 90°C for 0.5h, filtered, and ammonia water is added to the filtrate to obtain aluminum hydroxide precipitation, washed and filtered, the aluminum hydroxide solid is calcined alumina product , The filtrate is evaporated and crystallized to obtain solid ammonium sulfate for recycling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com