Method for detoxifying, emission-reducing and deeply treating wastewater of electronic electroplating industry

A technology for industrial wastewater and advanced treatment, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. , to achieve the effect of uniform surface pore structure, high mechanical strength and good product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

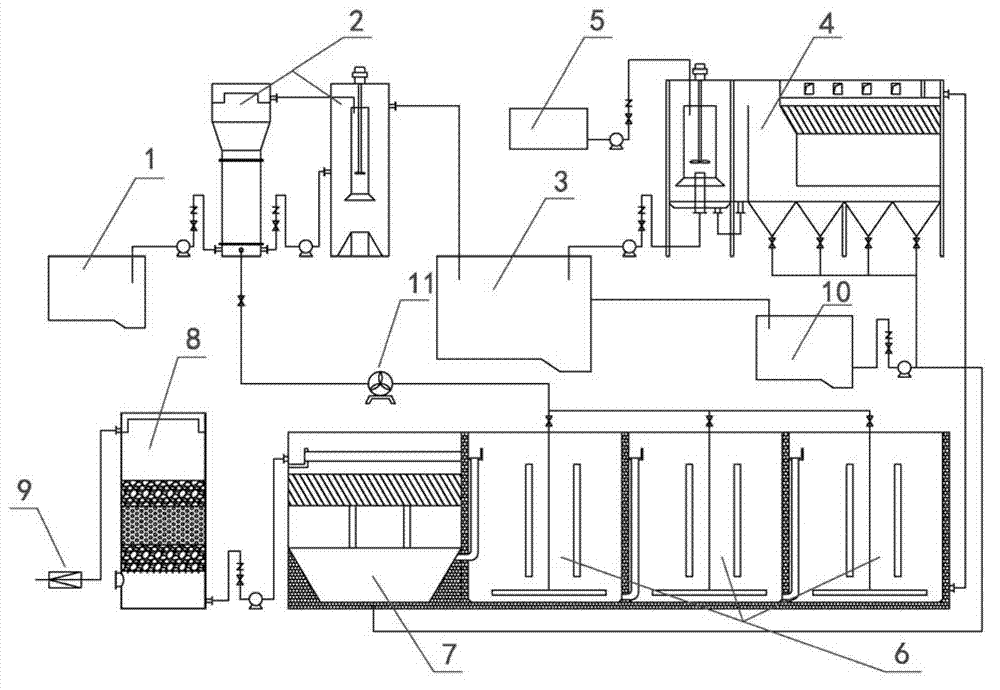

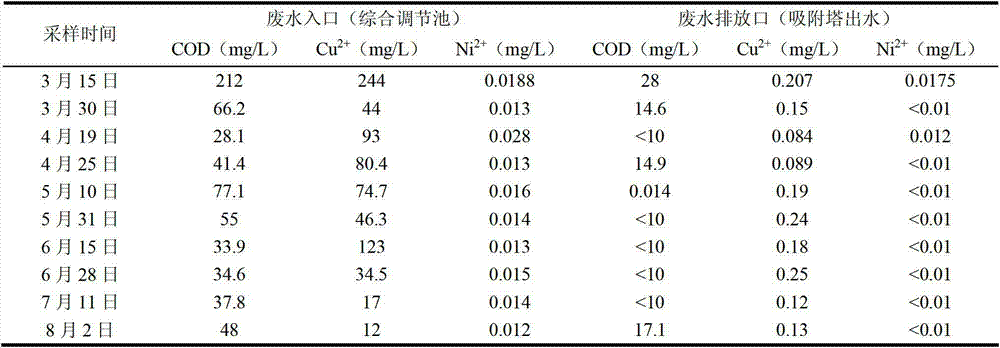

[0034] Adopt the method of the present invention to process the waste water of a printed circuit board production enterprise in Guangzhou Economic and Technological Development Zone, its flow process is as follows figure 1 As shown, it specifically includes the following steps:

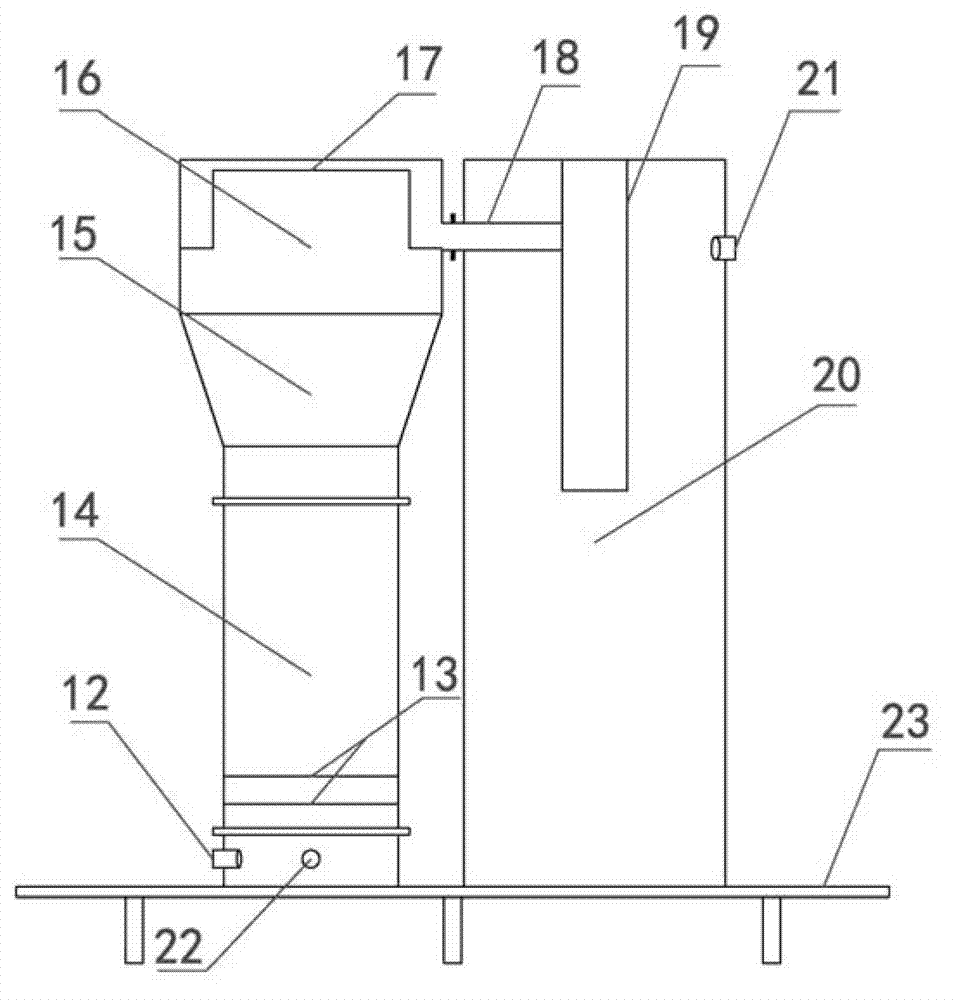

[0035] (1) Pass the printed circuit board complexed copper wastewater into the iron-carbon micro-electrolysis reactor 2 (its structure is as follows figure 2 As shown, that is, the pilot plant disclosed in "Research on the Treatment of EDTA Complex Copper Wastewater by Internal Electrolysis of Iron Flakes" by He Haopeng, Wu Xiuwen, Zhang Shaomin, etc.), the pH value of the water inlet 12 is controlled at about 2.5, and by controlling the water inlet The flow rate ensures that the HRT of the wastewater in the fluidization zone 14 is about 30 minutes, and then the wastewater passes through the settling zone 15, the static zone 16, crosses the overflow weir 17, enters the return tower 20 from the divers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com