Biodegradable composite film material with controllable degradation rate and preparation method thereof

A biodegradable and composite film technology, applied in the field of biodegradable composite film materials and their preparation, can solve the problems of physical and mechanical properties such as tensile strength drop, environmental pollution of polymer fragments, non-biodegradability, etc., and achieve controllable Degradability, high tear strength, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

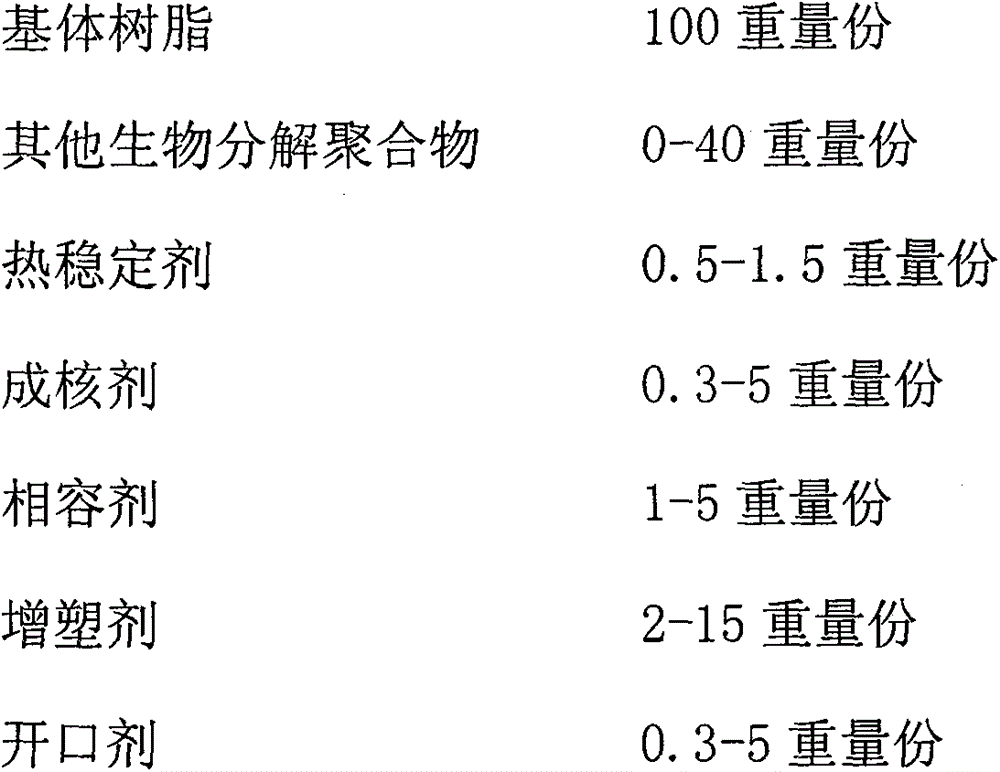

Method used

Image

Examples

Embodiment 1

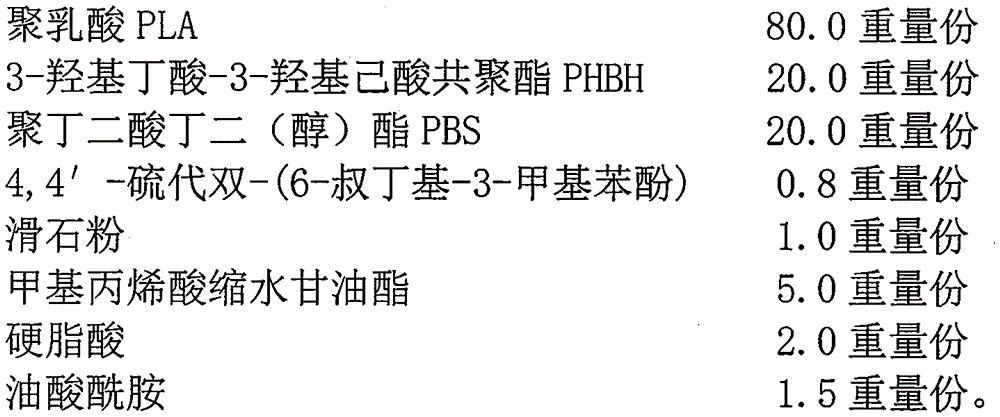

[0035] Embodiment 1: take each component by following formula and parts by weight

[0036]

[0037] The preparation method and conditions are set as:

[0038] (1) Dry the matrix resin and modifier in an oven at 40-80°C for 6-10 hours, then weigh the raw materials of each component according to the proportion, and pre-mix manually, and put the pre-mix on the twin-screw extruder Extrusion granulation. The temperature setting of the twin-screw extruder is: zone one, 110-145°C; zone two, 120-160°C; zone three, 145-185°C; zone four, 145-185°C; zone five, 145-185°C ; Machine head, 145-160°C.

[0039](2) The above-mentioned composite polymer pellets are extruded and blown into a film by single-screw, and the temperature of the single-screw extruder is set as: the first zone, 110-130°C; the second zone, 130-150°C; the third zone, 140-170°C; zone four, 140-185°C; zone five, 140-185°C; zone six, 140-160°C; die temperature, 145-160°C. Among them, the screw speed is 30-60rpm, the p...

Embodiment 2

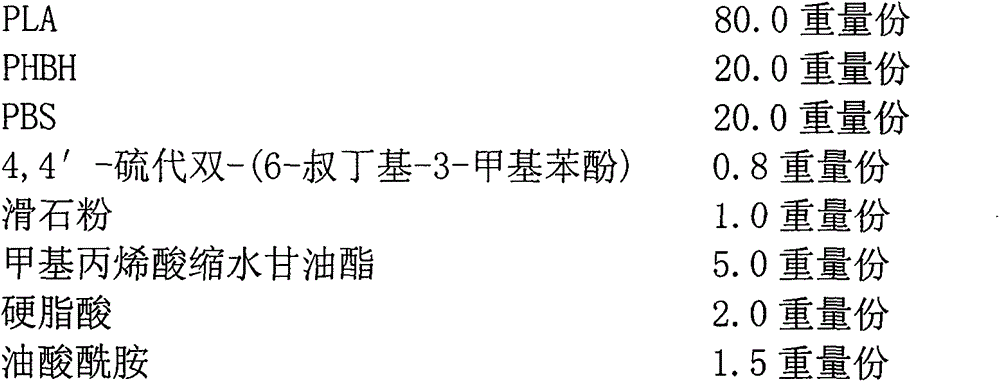

[0043] Embodiment 2: take each component by following formula and parts by weight

[0044]

[0045] Processing conditions and parameters see embodiment 1;

[0046] The properties of the products obtained are shown in Table 2.

[0047] Table 2: Film Thickness 19μm

[0048]

Embodiment 3

[0049] Embodiment 3: take each component by following formula and parts by weight

[0050]

[0051]

[0052] Processing conditions and parameters see embodiment 1;

[0053] The properties of the products obtained are shown in Table 3.

[0054] Table 3: Film Thickness 35μm

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com