Method for preparing Ni-P-CNT (Carbon nanotube) nano composite coating

A composite coating, ni-p-cnt technology, applied in the application field of chemical plating, can solve the problem that the dispersion is not well solved, the stability of the plating solution, and the co-deposition mechanism of nanoparticles and metal ions has no perfect theory. Explanation and other issues to achieve the effect of superior performance, excellent mechanical properties, good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The carbon nanotube (Carbon nano-tube, CNT, hereinafter referred to as CNT) raw material was boiled in concentrated sulfuric acid for 6 hours, and finally washed with deionized water to neutrality, filtered and placed in a drying oven at 80°C for drying.

Embodiment 2

[0052] The CNT raw material was boiled in concentrated nitric acid for 6 hours, and finally washed with deionized water until neutral, filtered and then put into a drying oven for drying at 80°C.

Embodiment 3

[0054] The CNT raw material was boiled for 6 hours in concentrated sulfuric acid and concentrated nitric acid with a volume fraction of 3:1, and finally washed with deionized water to neutrality, filtered, and then dried in a drying oven at 80°C.

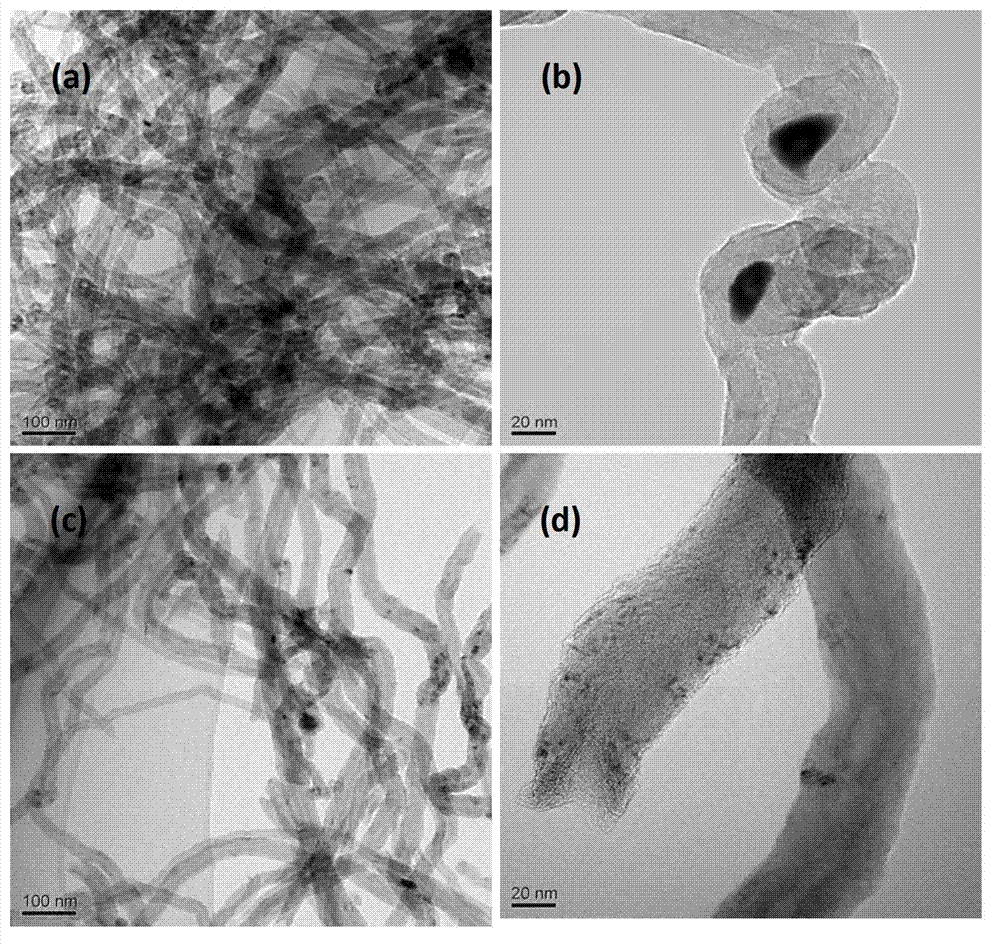

[0055] figure 2 It is the TEM picture of the CNT before and after acid treatment in Example 3. From figure 2 (a), figure 2 (c) It can be seen that the entanglement and agglomeration of CNTs after acid treatment is significantly reduced. Simultaneous comparison figure 2 (b), figure 2 (d) It is not difficult to find that after pickling and oxidation, black groups appeared on the surface of carbon nanotubes, which were later confirmed to be hydroxyl or carboxyl groups.

[0056] image 3 Infrared spectrum pictures of carbon nanotubes (CNTs) before and after acid treatment in Example 3. Depend on image 3 It can be seen that no matter before or after concentrated acid treatment, there are obvious hydroxyl peaks (3444cm -1 )...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com