Double-row six-cylinder radial type common-rail oil feed pump

An oil supply pump and common rail technology, which is applied in the field of double-row six-cylinder radial common rail oil supply pumps, can solve the problem that the radial common rail oil supply pump cannot meet the performance requirements of large oil supply volume, and the inline common rail oil supply pump cannot meet the requirements Problems such as compact structure and poor oil pump redundancy can achieve the effect of improving redundancy and reliability, simple structure and low driving torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific drawings and embodiments.

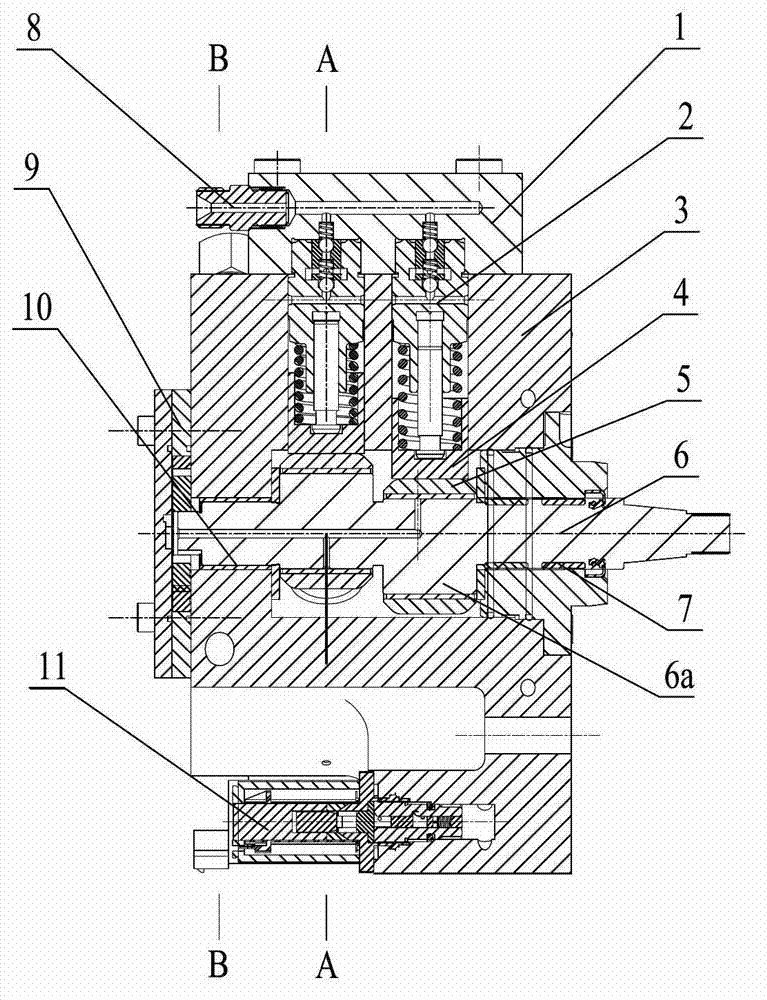

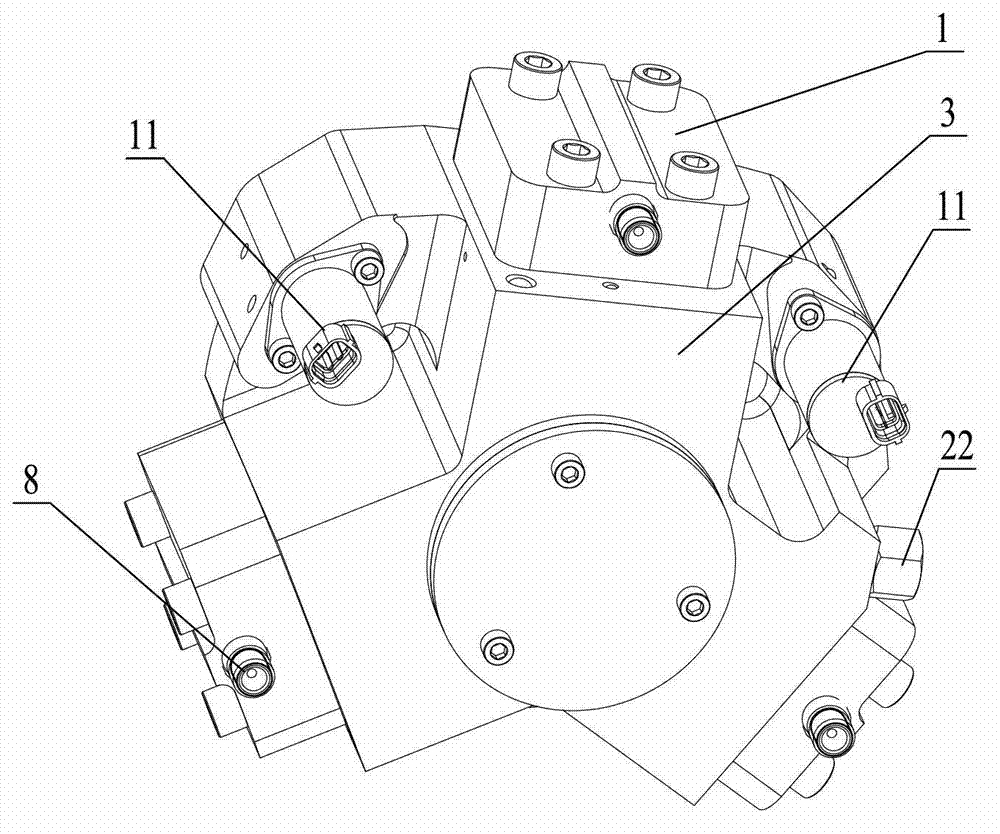

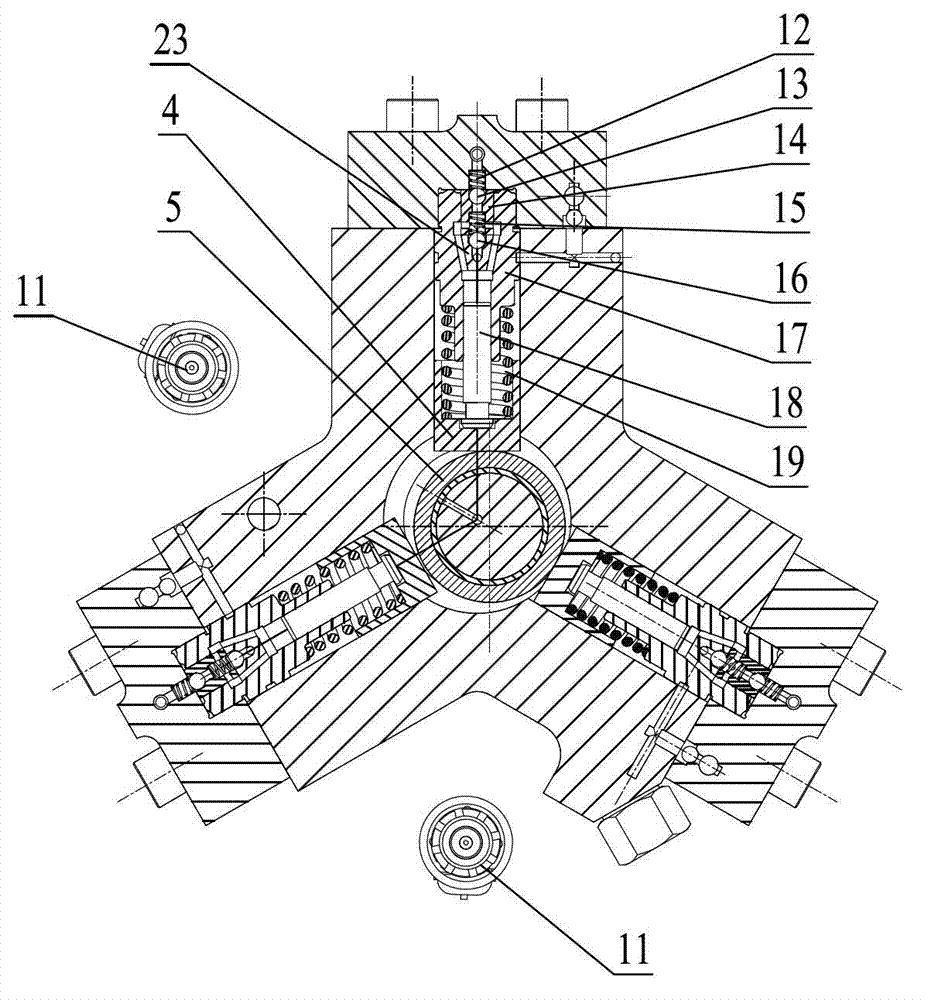

[0023] Such as Figure 1~Figure 4As shown, the pump body 3 is provided with an axial center hole and six radial installation cavities around the periphery of the axial center hole, and the six radial installation cavities are located in the axial direction of the pump body 3 Divided into two rows, divided into three rows in the circumferential direction of the pump body 3, the inner end opening of each radial installation cavity communicates with the axial center hole; three pump heads 1 uniformly distributed along the circumferential direction are installed on the outside of the pump body 3 Each pump head 1 is provided with two cavities in the axial direction. After the pump head 1 is installed on the pump body 3, the cavities on the three pump heads 1 are aligned with the three rows of radial installation cavities on the pump body 3. One to one correspondenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com