System utilizing absorption heat pump to recover exhaust steam waste heat of power station and heat boiler supply water

An absorption heat pump and heating boiler technology, applied in heat recovery systems, feed water heaters, energy-saving heating/cooling, etc., can solve the problems of increasing initial investment, high initial investment of electric heat pumps, and reducing heat utilization efficiency, etc., to reduce equipment Investment, avoiding irreversible losses, and the effect of short investment return time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technology of the present invention will be described below in conjunction with specific embodiments.

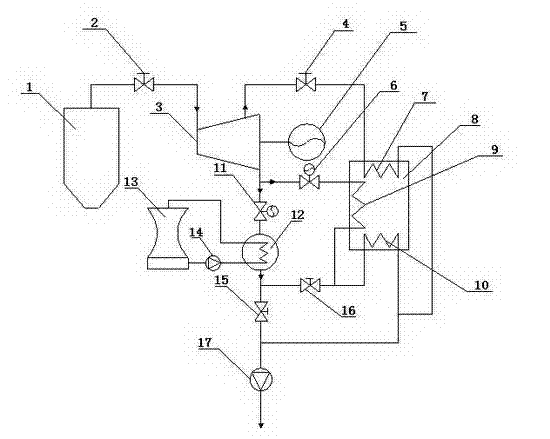

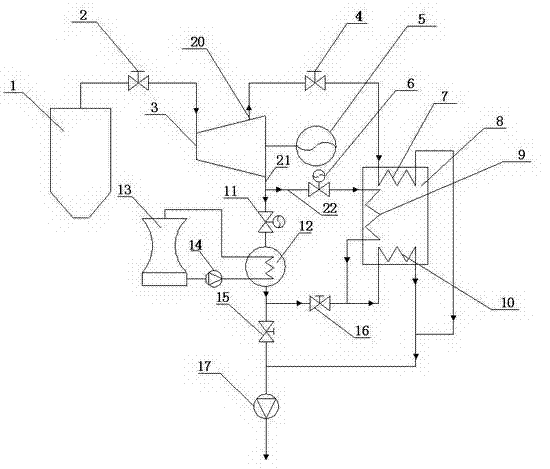

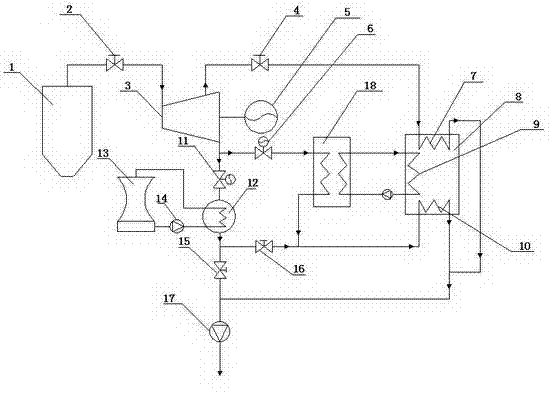

[0031] figure 1 It is a schematic diagram of the pipeline connection structure of the absorption heat pump recovery power station exhaust steam waste heat and heating boiler feed water system of a preferred embodiment of the present invention, figure 2 for figure 1Schematic diagram of pipeline connection and fluid flow of the system when the generator set and the absorption heat pump are running in the embodiment.

[0032] Such as figure 1 , figure 2 As shown, the absorption heat pump of the present invention recovers waste heat from power plant exhaust and heats boiler feed water, including a generator set and an absorption heat pump. The generator set includes a boiler 1 that generates high-temperature and high-pressure steam, a generator 5, and a generator that rotates to drive the generator 5 to generate electricity. Steam turbine 3 , condenser 12 , c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com