Negative active material, method of preparing the negative active material, negative electrode and lithium battery

A negative electrode active material and a negative electrode technology are applied in the fields of negative electrode active materials and their preparation, negative electrodes and lithium batteries, and can solve the problems of unsatisfactory electrical conductivity and life characteristics of negative electrode active materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

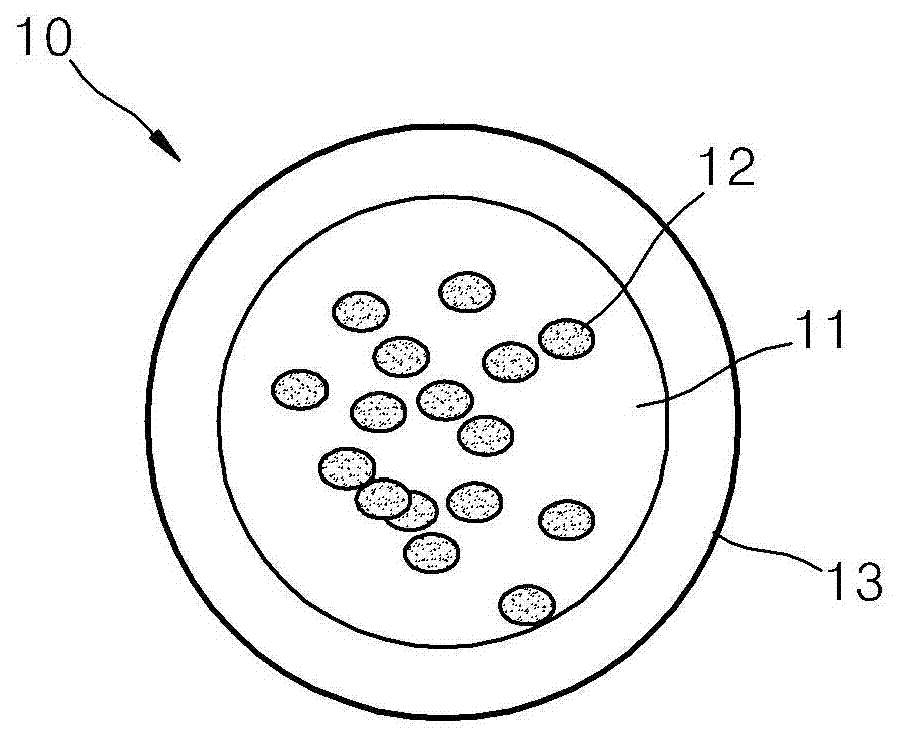

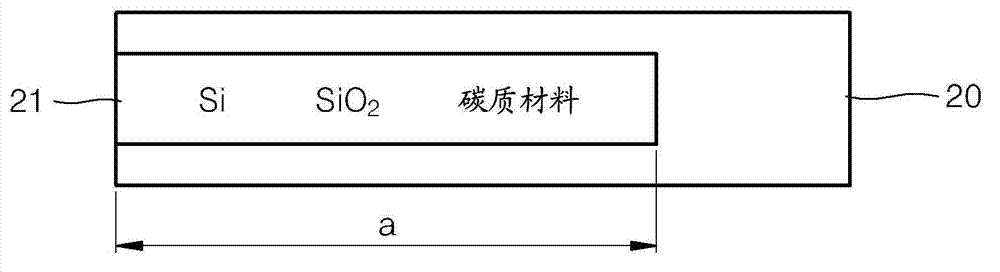

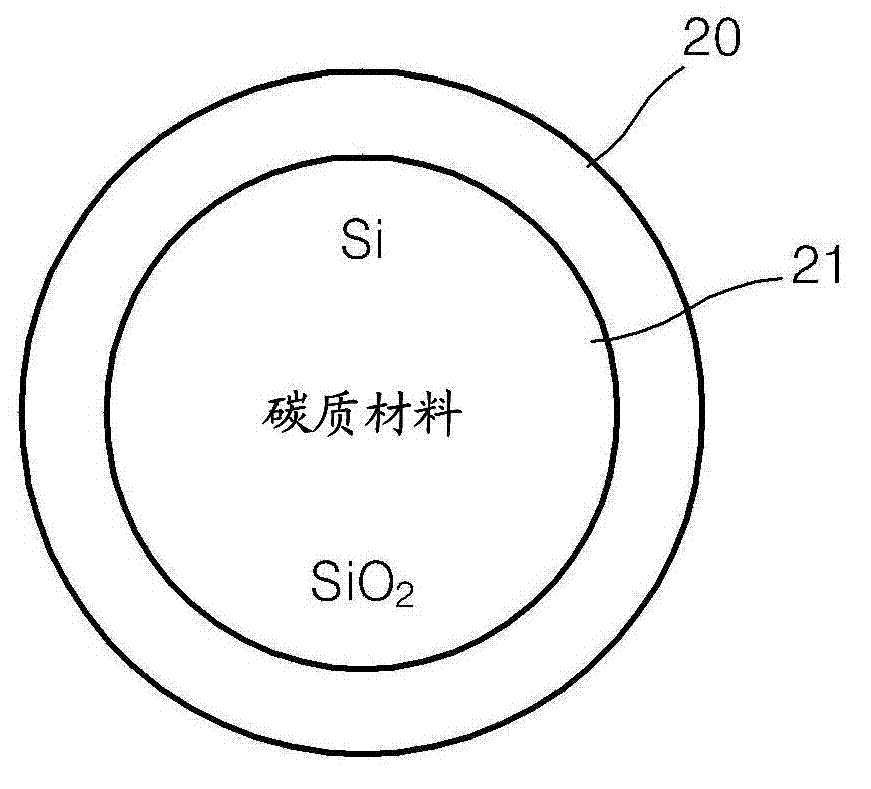

[0116] Example 1: Preparation of negative electrode active material

[0117] In a graphite rod with a diameter of about 25 mm and a length of about 300 mm, a sample entry portion with a diameter of about 22 mm and a height of about 200 mm is formed, and 30 g of carbon black, 60 g of SiO 2 and 100 g of Si were sequentially filled into the sample entry portion to prepare a negative electrode for arc discharge.

[0118] Separately, a molybdenum (Mo) electrode was used as a positive electrode for arc discharge.

[0119] In the arc discharge apparatus, set the negative electrode at an interval of approximately 300 mm from the positive electrode, and then perform pumping until the pressure of the chamber drops to approximately 2 × 10 -1 Torr, next filled with argon. It was then supplied with a current of about 300A and a DC voltage of about 40V to perform arc discharge, thereby completing the preparation of the negative electrode active material.

example 2

[0120] Example 2: Preparation of negative electrode active material

[0121] A negative electrode active material was prepared in the same manner as in Example 1 except that 20 g of carbon black was used in preparing the negative electrode for arc discharge.

example 3

[0122] Example 3: Preparation of negative electrode active material

[0123] A negative electrode active material was prepared in the same manner as in Example 1 except that 10 g of carbon black was used in preparing the negative electrode for arc discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Full width at half maximum | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com