Direction-controllable laser device system

A technology for lasers and laser arrays, applied in laser devices, devices for controlling laser output parameters, semiconductor laser devices, etc., can solve the problems of increased array unit spacing, complex structure, huge control system, etc., and achieve precise adjustment of deflection angle, The effect of increasing the deflection angle and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

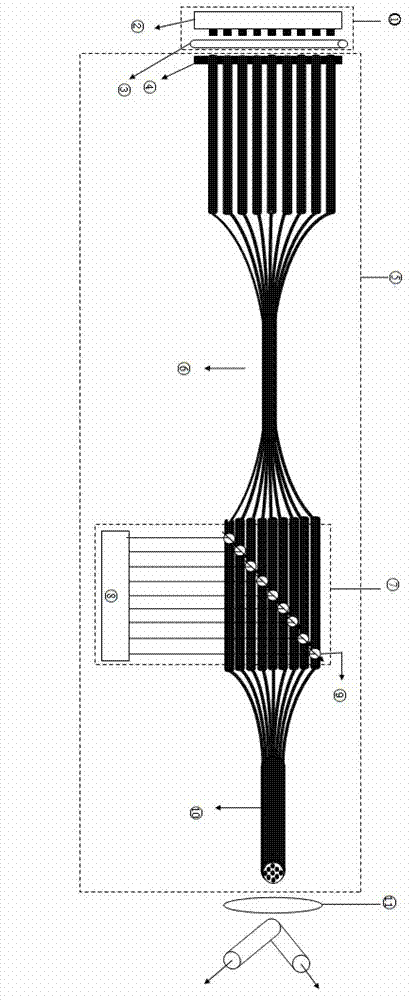

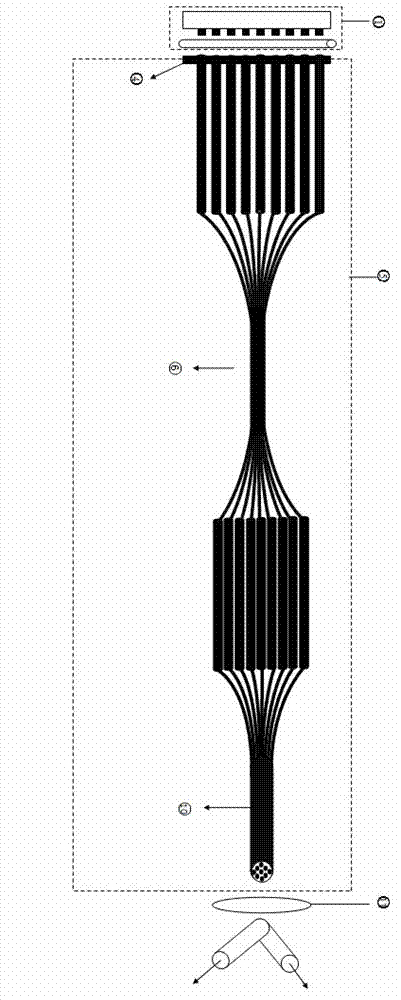

[0032] figure 1 It is the device diagram of the phased array laser system of the present invention. The invention uses a semiconductor array laser as a laser source, which has high conversion efficiency and small volume; the optical fiber tapered array is used as a waveguide, which has good light guiding performance, does not change the properties of the beam, has low loss, and has good flexibility; using a self-adjusting phase-locking method, Developed a new type of combined laser (such as figure 2 shown), and on this basis, each waveguide unit is phase-controlled to achieve fast and flexible beam direction driving. In particular, with the development of semiconductor lasers and the development of more waveguide devices, the present invention has great room for development.

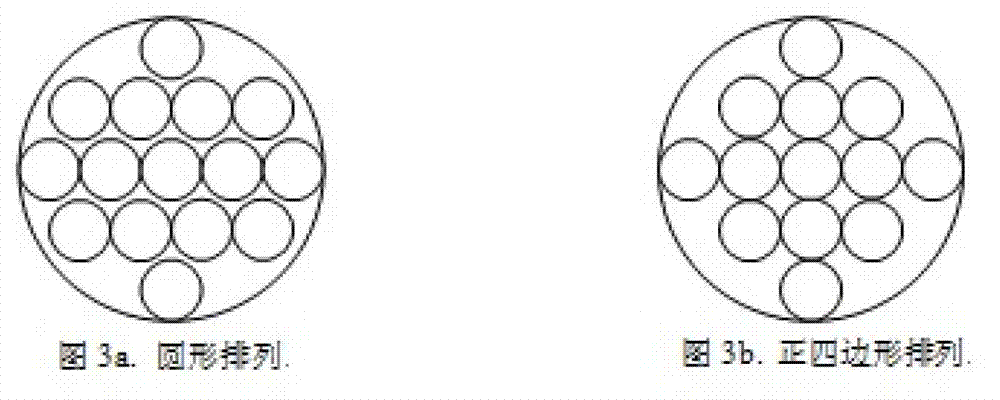

[0033] Firstly, the manufacturing method of the fiber taper array of the present invention is introduced. The fiber taper array is composed of three parts: alignment section I, taper bundle coupling s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com