Method and device for the control of formation and propagation of bacterial cultures, viral, fungal cultures, mildew, and micro organisms etc. on the condenser coil in larger refrigeration systems

A technology for bacterial culture and condensers, applied in household refrigeration units, refrigeration and liquefaction, evaporators/condensers, etc., can solve problems such as lack of effective cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

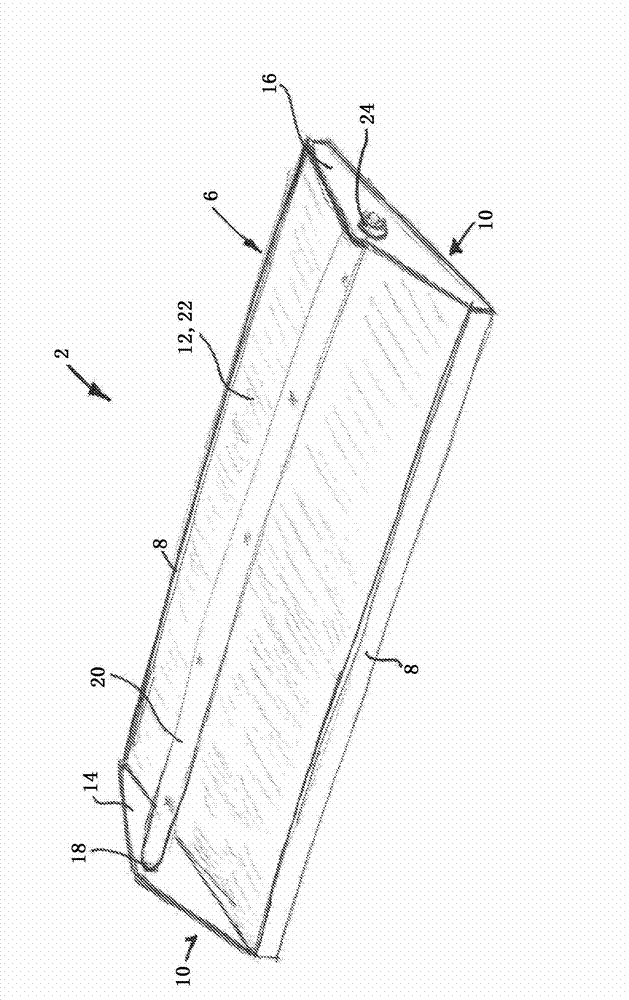

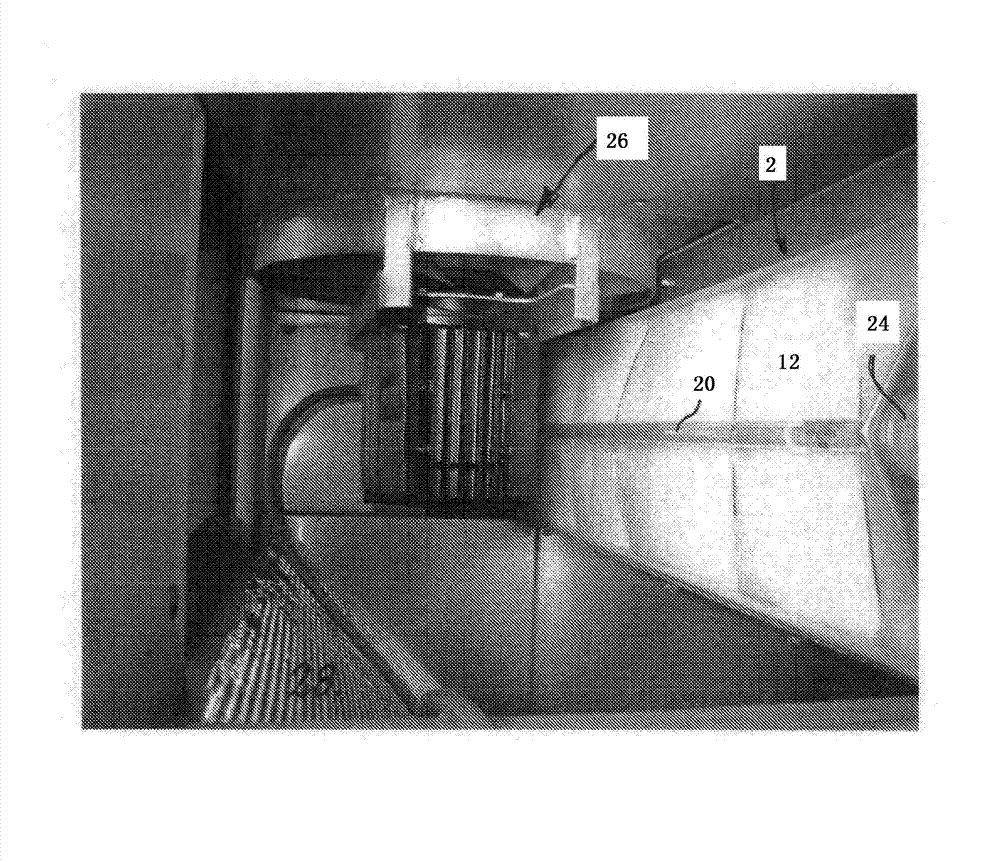

[0044] in figure 1 An embodiment of the device 2 used to combat the formation and propagation of bacterial cultures and microorganisms on the surface of the condenser in the refrigeration equipment / unit 4, see Figure 3A with 3B .

[0045] In the illustrated embodiment, the device 2 includes a rectangular frame 6 having two long sides 8 and two short sides 10, in which a filter material 12 containing titanium dioxide is placed. The short side 6 of the frame 2 includes end plates 14, 16 having a cross section that exactly forms a triangle. A console 18 for installing a UV light source 20 is arranged in the end plates 14, 16, the UV light source 20 is connected to an unshown power supply associated with the refrigeration equipment / unit 4 via a cable (not shown). In order to illuminate the entire surface of the filter 22, a UV light source is arranged at a certain distance from the filter material 12 containing titanium dioxide.

[0046] On the outer side of at least one end plate 14...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com