Anticorrosion anticrack reinforcing agent for concrete

A reinforcing agent and concrete technology, which is applied in the field of anti-corrosion and anti-cracking reinforcing agents for concrete, which can solve the problems of poor shrinkage reduction effect and severe erosion of underground structures, and achieve the effects of increased life, enhanced volume stability, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The purpose of this embodiment is to achieve the best shrinkage reduction effect, to meet the engineering anti-crack, anti-carbonization and anti-corrosion and anti-cracking reinforcing agent for low-cost concrete that is resistant to chlorine salt erosion. The components are as follows by weight %:

[0037] Ethylene oxide polymer 5%, polypropylene fiber 4%, anti-chlorine salt erosion component 80%, polysiloxane 10%, rosin 0.5%, citric acid 0.5%.

[0038] The above-mentioned components are crushed into granules that can be put into the grinder, mixed evenly, and the mixed material is ground until the particle size reaches 300-500 mesh, and mixed with polyacrylonitrile fiber to prepare the anti-corrosion and anti-cracking enhancer for A-type concrete.

Embodiment 2

[0040] The purpose of this embodiment is to achieve shrinkage reduction effect, while satisfying engineering anti-cracking, anti-corrosion and anti-corrosion anti-crack reinforcing agent for concrete of chlorine salt erosion, each component is as follows by weight %:

[0041] Ethylene oxide polymer 2%, polyacrylonitrile fiber 6%, anti-chlorine salt corrosion component 60%, polysiloxane 30%, rosin 0.5%, citric acid 1.5%.

[0042] The above-mentioned components are broken into grindable granules, mixed evenly, and the mixed material is ground until the particle size reaches 300-500 mesh, and mixed with polyacrylonitrile fibers to prepare a B-type concrete anti-corrosion and anti-cracking enhancer.

Embodiment 3

[0044] The purpose of this embodiment is to achieve a medium shrinkage effect, while satisfying engineering anti-crack, anti-carbonization and anti-corrosion anti-cracking reinforcing agent for concrete, the components are as follows by weight %:

[0045] Ethylene oxide polymer 3%, polyacrylonitrile fiber 6%, anti-chlorine salt corrosion component 70%, polysiloxane 20%, rosin 0.5%, citric acid 0.5%.

[0046] The above-mentioned components are crushed into granules that can be put into the grinder, mixed uniformly, the mixed material is ground until the particle size reaches 300-500 mesh, and mixed with polyacrylonitrile fiber to prepare the anti-corrosion and anti-cracking enhancer for C-type concrete.

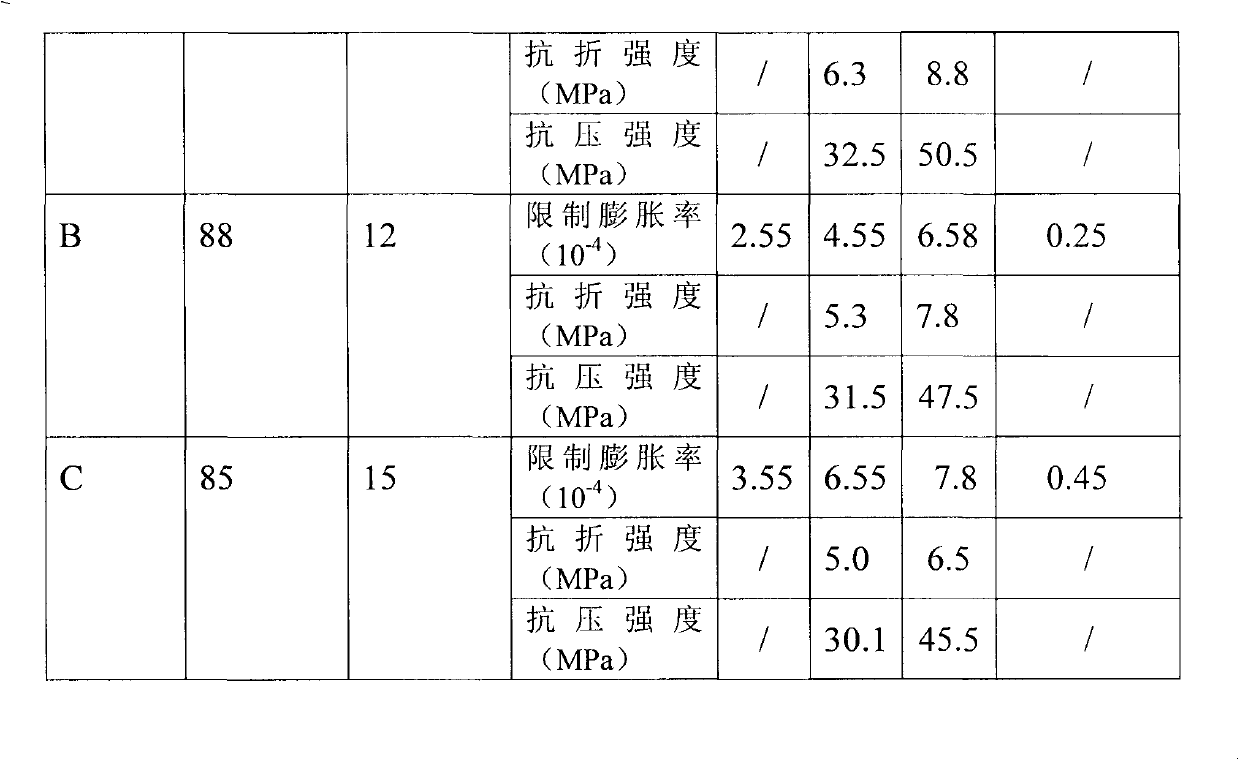

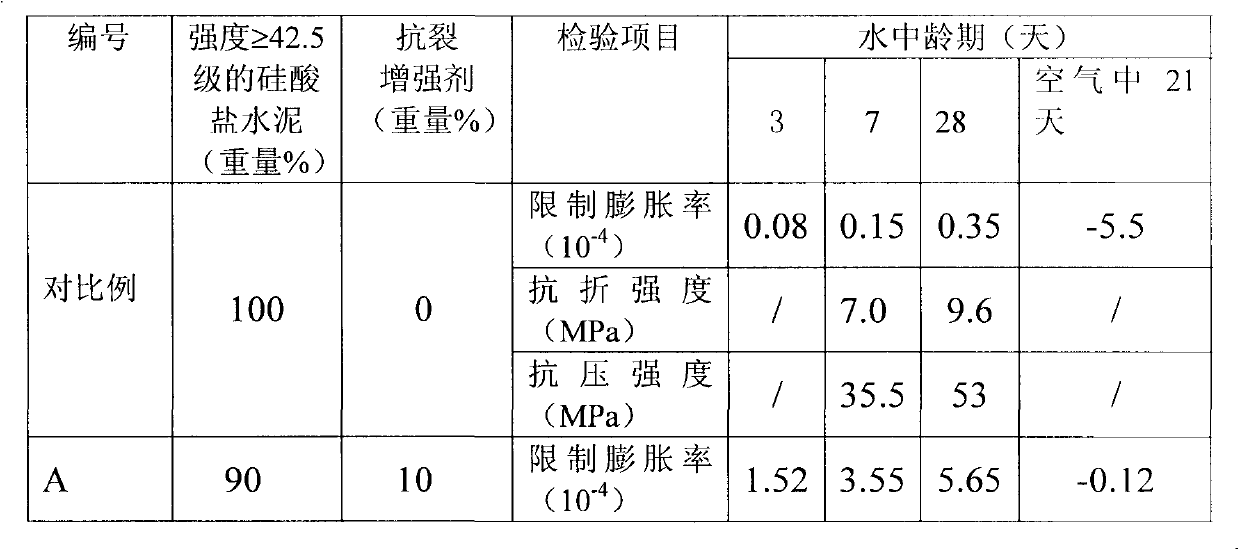

[0047] The various indicators of the anti-corrosion and anti-crack reinforcing agent for concrete of embodiment 1-3

[0048]

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com