Preparation method of pharmaceutic adjuvant grade Glyceryl Behenate

A technology of glyceryl behenate and pharmaceutical excipients, which is applied in the field of drug synthesis, can solve the problems of unsuitable pharmaceutical excipient grade glyceryl behenate, etc., and achieve the effects of less "three wastes", convenient product refining, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

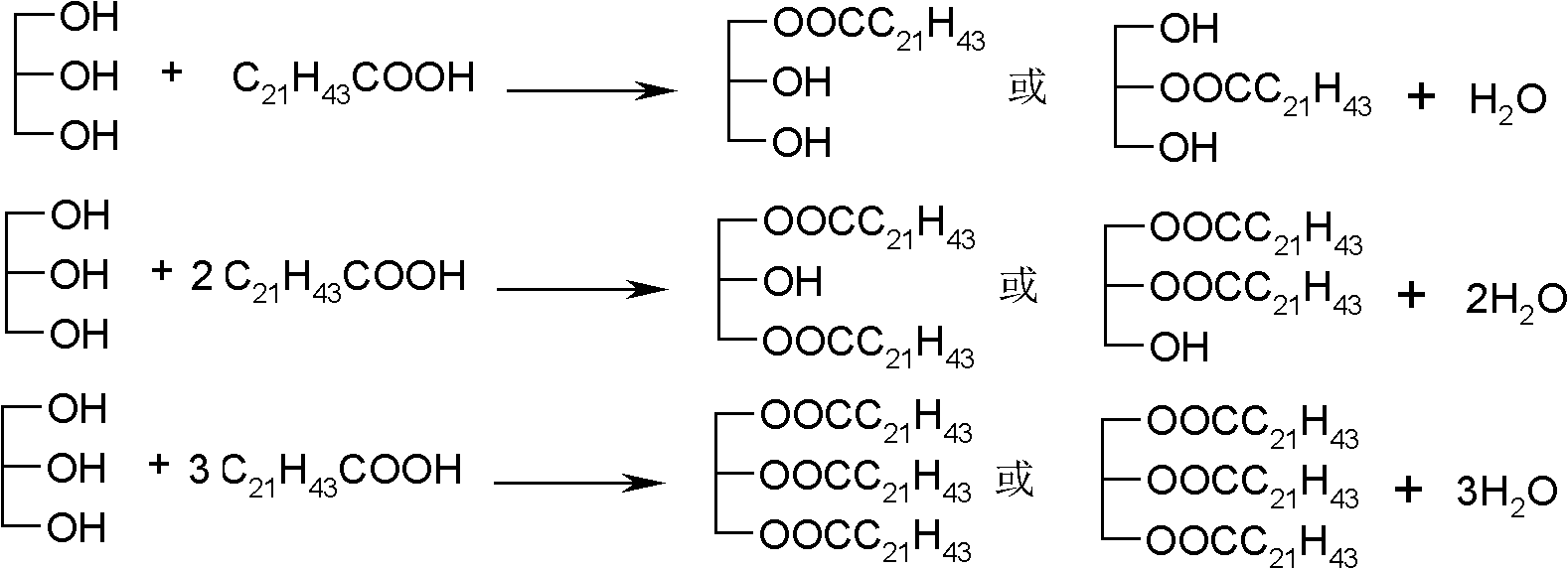

Method used

Image

Examples

Embodiment 1

[0024] Put 50.1kg of behenic acid and 13.5kg of glycerin (molar ratio is 1:1) into the glass-lined reactor, heat up to 105°C for dehydration reaction for 10 hours (control acid value1 H-NMR; 13 C-NMR; C-H correlation spectrum; long-range C-H correlation spectrum confirms that it is a mixture of monoester, diester and triester.

Embodiment 2

[0026] Put 50.0kg behenic acid and 10.0kg glycerin (molar ratio is 1.35:1) into the glass-lined reactor, heat up to 120°C for dehydration reaction for 8 hours (control acid value 1 H-NMR; 13 C-NMR; C-H correlation spectrum; long-range C-H correlation spectrum confirms that it is a mixture of monoester, diester and triester.

Embodiment 3

[0028] Put 51.2kg of behenic acid and 8.6kg of glycerol (molar ratio: 1.6:1) into the glass-lined reactor, heat up to 140°C for dehydration reaction for 8 hours (control acid value 1 H-NMR; 13 C-NMR; C-H correlation spectrum; long-range C-H correlation spectrum confirms that it is a mixture of monoester, diester and triester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com