Method and apparatus for mechanical defoaming of coking tower

A mechanical defoaming and coking tower technology, applied in the petrochemical field, can solve the problems of high cost and complex composition of raw materials, and achieve the effects of small footprint, low operating cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

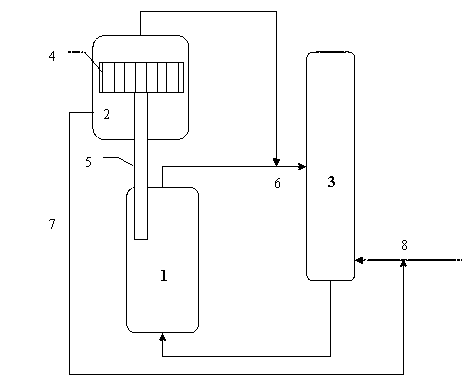

[0027] A centrifugal defoamer is installed on the top of the coke tower. The length of the foam suction pipe of the centrifugal defoamer penetrates into the coke tower is 10% of the height of the coke tower. When the foam layer reaches the foam suction pipe, the centrifugal defoamer is started. The properties of the test raw materials are shown in Table 1, and the process operating conditions and test results are shown in Table 2. The embodiment mainly investigates that in the absence of a defoamer, the normal operation cycle of the coke drum can also be achieved by relying on a centrifugal defoamer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com