Recycling method for calcium-free chromium slag sintered building block

A technology of calcium-free chromium slag and agglomeration, which is applied in the field of detoxification and recycling of solid calcium-free chromium slag, can solve the problems of complicated treatment procedures, achieve low processing costs, realize recycling and reduce environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

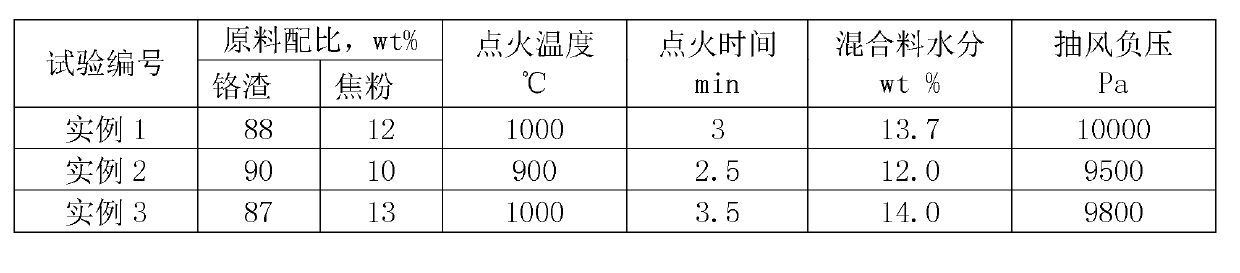

[0022] Table 1 Raw material configuration and process parameter setting of Examples 1-3

[0023]

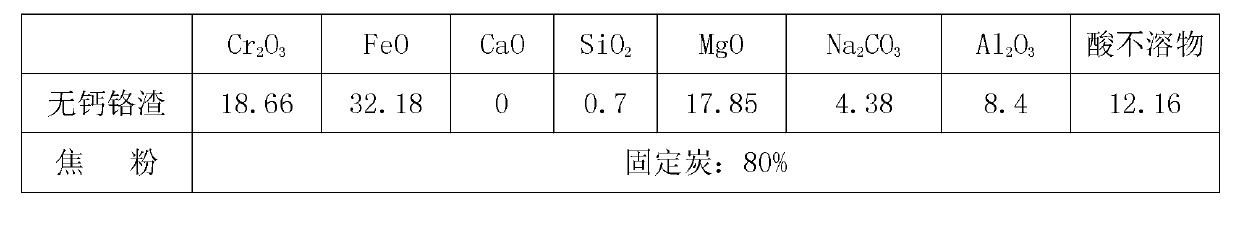

[0024] Table 2 Composition of raw materials and fuels (%)

[0025]

[0026] The sintering process indicators are shown in Table 3. The particle size composition of sinter is shown in Table 4.

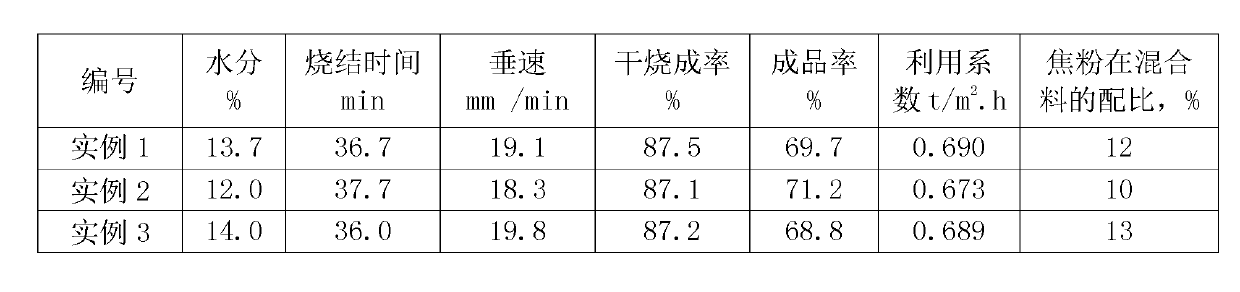

[0027] Table 3 Examples 1-3 Sintering cup test process indicators

[0028]

[0029] Table 4 The particle size composition of sintered ore in Examples 1-3 (wt%)

[0030] Granular composition

>40mm

40~10mm

10~5mm

<5mm

Example 1

23.36

39.17

7.2

30.30

Example 2

22.87

40.02

7.6

29.51

Example 3

22.02

38.12

6.9

32.96

[0031] A kind of calcium-chromium-free slag sintering and agglomeration recycling method,

[0032] (a), calcium-free chromium slag and coke powder are made into mixture according to Table 1;

[0033] (b), the mixture is mixed in a primary mixer and moistened with water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com