Sealing water tank of phosphorus diffusion furnace exhaust tube

A technology for sealing water tanks and exhaust pipes, applied in the directions of diffusion/doping, crystal growth, electrical components, etc., can solve the problems of phosphorus oxychloride leakage, operator harm, etc., to reduce the corrosion rate, avoid poisoning accidents, increase The effect of running load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

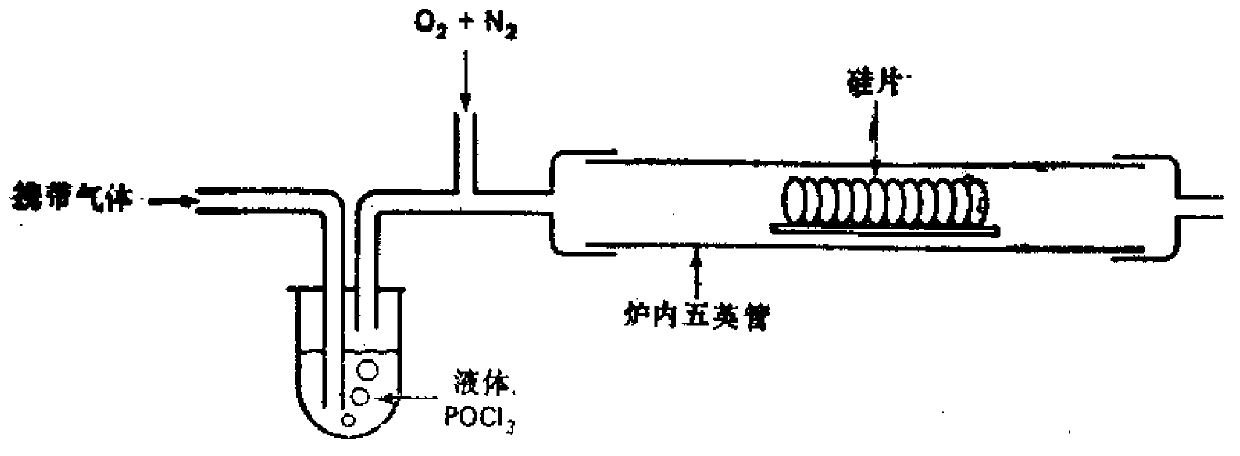

Method used

Image

Examples

Embodiment Construction

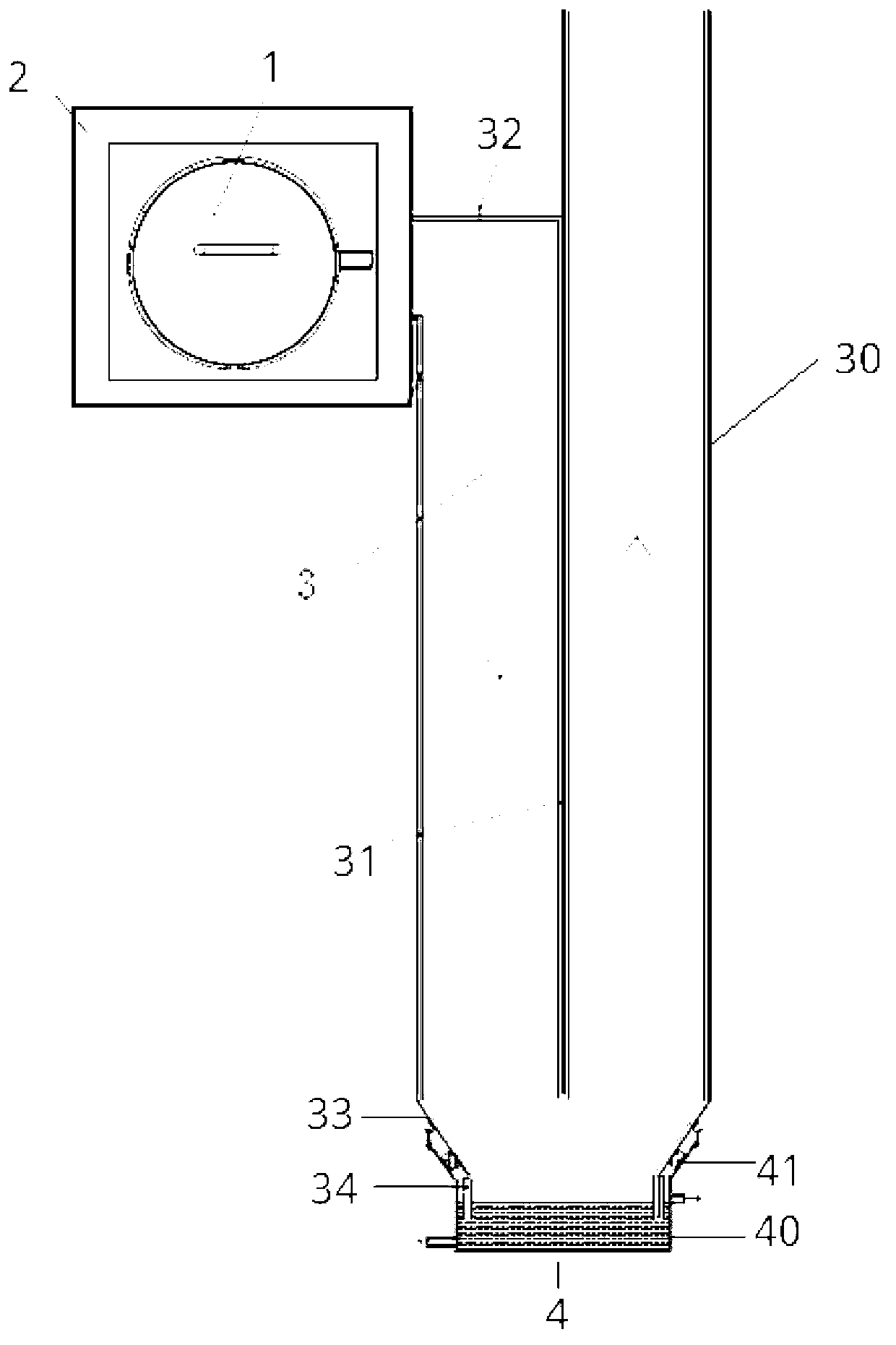

[0026] Such as figure 2 Shown, is the overall structure of the phosphorus oxychloride removal device of the phosphorus diffusion furnace applying the sealed water tank of the present invention, which includes a buffer tank 2, an exhaust pipe 3 and a sealed water tank 4, and also includes a Figure 7 Cooling tank 5 shown.

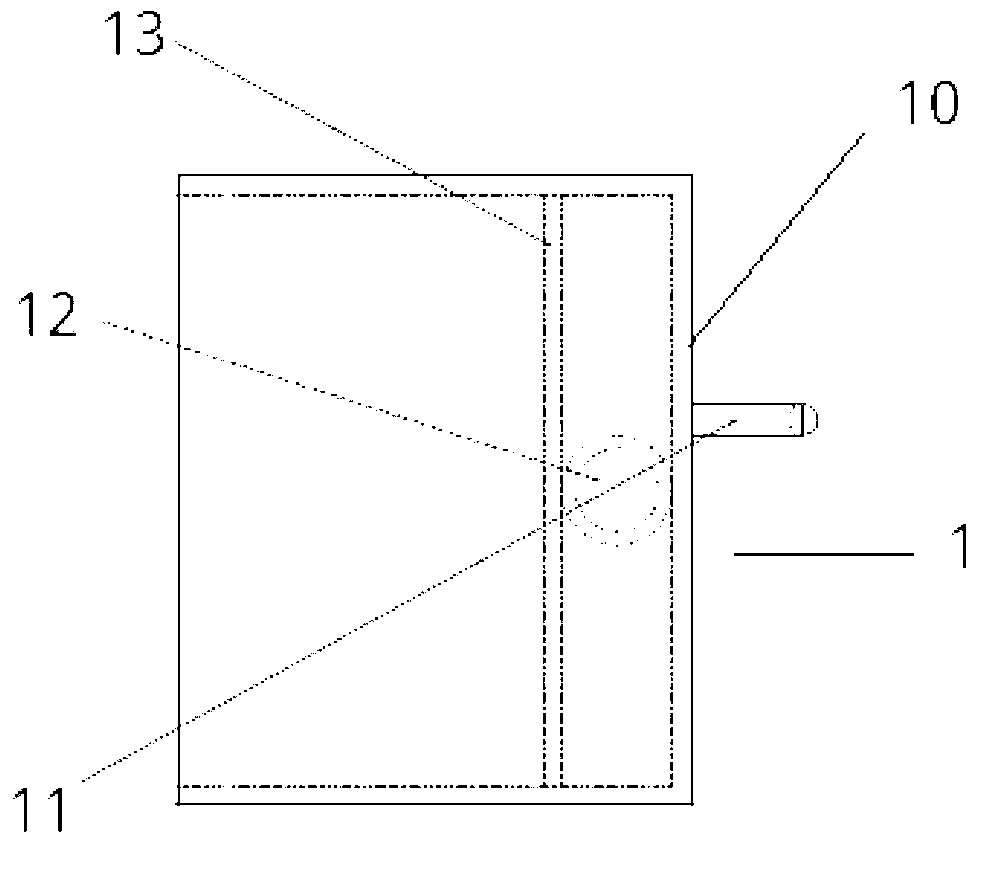

[0027] Such as image 3 and Figure 4 As shown, it is a phosphorus diffusion furnace furnace tube furnace cap 1, which includes a cylindrical quartz material cap body 10 with a closed bottom, and an outwardly protruding opening mouth 12 is provided at the bottom of the cap body. A quartz snap ring 13 is welded on the inner wall, and the opening extension is arranged between the bottom surface of the snap ring and the bottom wall of the cap body. A quartz handle 11 is welded to the outer wall of the bottom of the cap body. The length of the opening extension mouth 12 is controlled at 3-5cm, and the inner diameter of the opening extension mouth is control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com