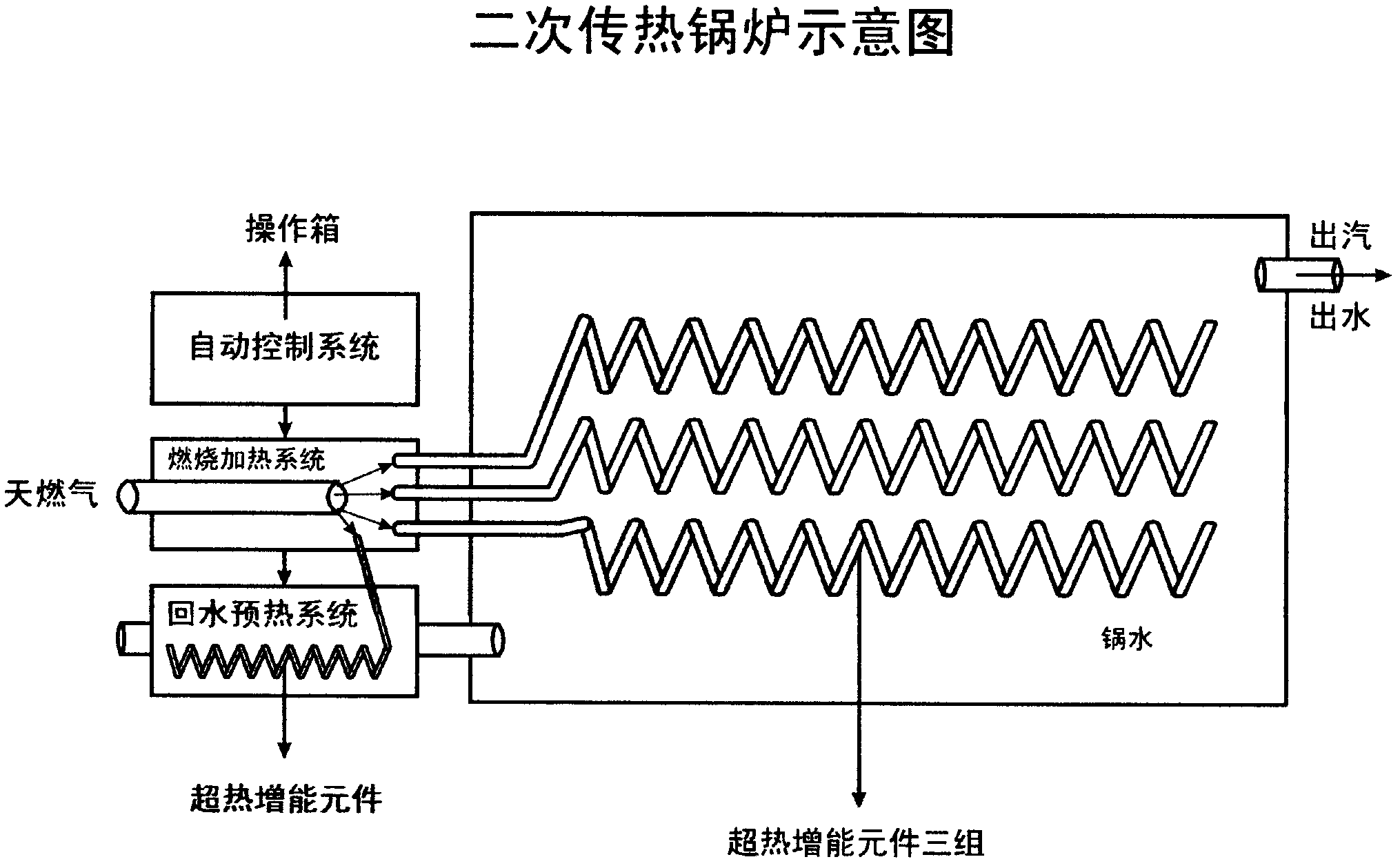

Secondary heat transmission boiler

A boiler and boiler body technology, applied in steam boilers, water heaters, fluid heaters, etc., can solve problems such as affecting sustainable development, insufficient railway capacity, road traffic damage, etc., and achieves reduction of secondary environmental pollution and economic benefits. Improve and improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0004] Ceramics and quartz are selected as different materials to make them superheated and energy-enhancing. The heat transfer workpiece adopts parallel multi-group or single-group type. The workpiece is placed in the primary heat transfer and secondary heat transfer water. According to the size of the boiler tonnage, , The water outlet is different, according to the steam outlet and the boiler with different water outlet requirements, the placement position of the secondary heat transfer and heat conduction components is implemented to make the thermal efficiency reach the best state. The other end of the heat-conducting workpiece is connected to a small combustion chamber. The heat source in the combustion chamber is natural gas, which heats the top of the heat-transfer workpiece. Because the heat-transfer working fluid and the heat-transfer device are made of ceramic or quartz, the closed container material is vacuumized. In this state, a variety of chemical composition wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com