Tin-doped silver-wrapped base metal slurry of back electrode of solar cell, and preparation method of slurry

A technology for solar cells and back electrodes, applied to conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve the problem of good solderability and adhesion, high battery conversion efficiency, and high price of pure silver powder and other problems, to achieve the effects of good weldability and adhesion, high battery conversion efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

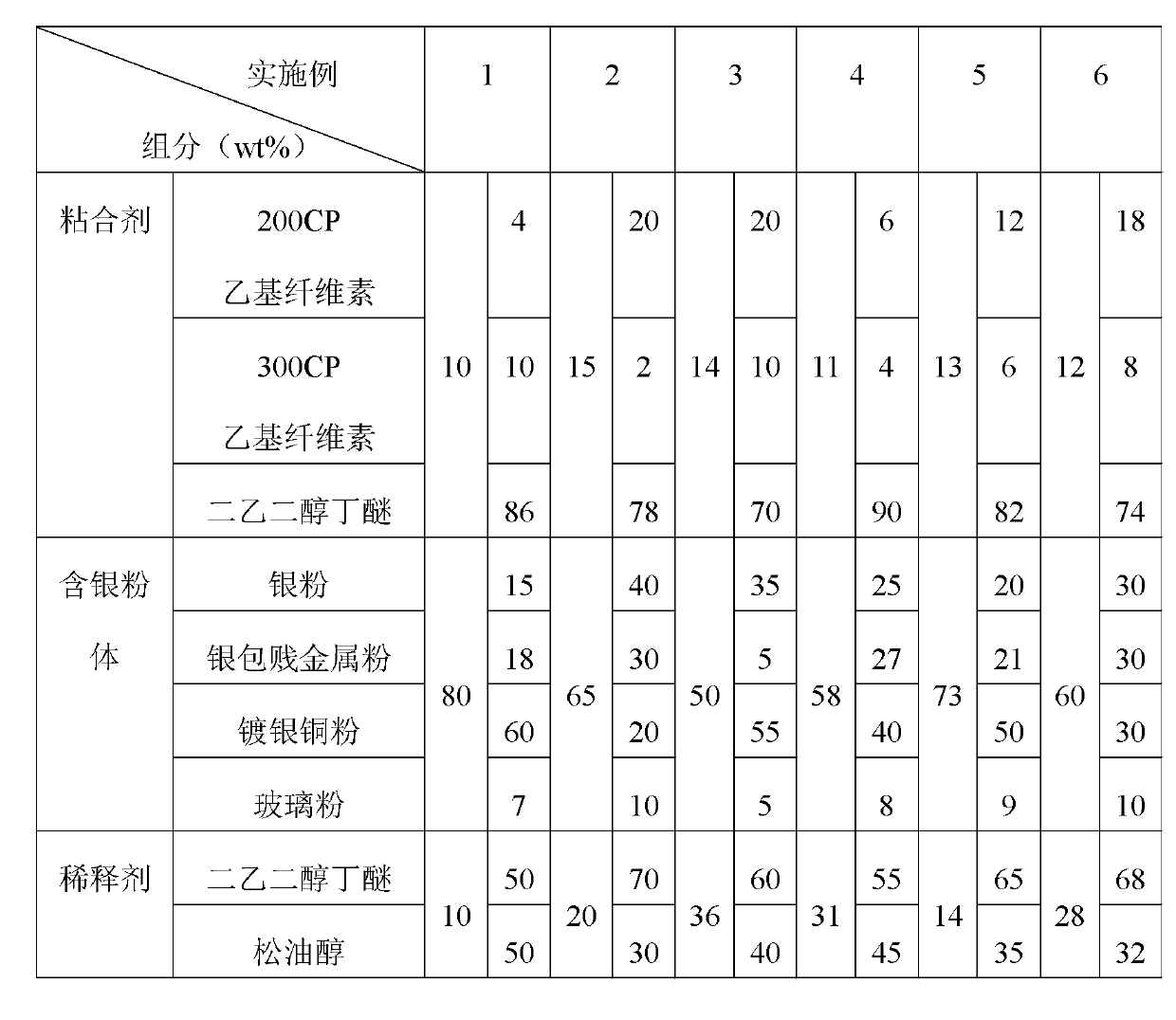

[0025] Embodiment: The formula of the silver-coated base metal paste doped with tin on the back electrode of the solar cell of Examples 1 to 6 of the present invention is shown in the following table 1:

[0026] Table 1 (unit: weight percentage)

[0027]

[0028] Wherein, the silver-coated base metal powder refers to silver-coated nickel powder or silver-coated copper powder or a mixture of the two. Moreover, in terms of weight percentage, the silver content in the silver-coated base metal powder is 2%-60%; the particle size of the silver-coated base metal powder is 1 micron-10 microns, and the silver-coated base metal powder The shape is at least one of spherical, flake and dendritic.

[0029] According to the above formula, the preparation method of the silver-coated base metal paste doped with tin on the back electrode of the solar cell of the present invention is as follows:

[0030] 1. Prepare the adhesive: mix ethyl cellulose with a dynamic viscosity of 200CP, ethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com