Preparation method of efficient calcium-based sepiolite phosphorus adsorbent and application thereof

A phosphorus adsorbent, sepiolite technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc. In order to achieve the effect of efficient and rapid removal, increase fixed capacity, and improve adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Preparation of calcium-based sepiolite phosphorus adsorbent

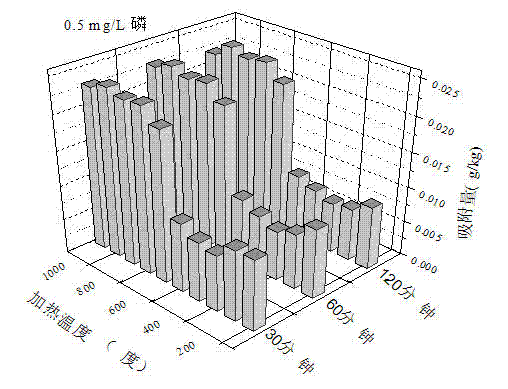

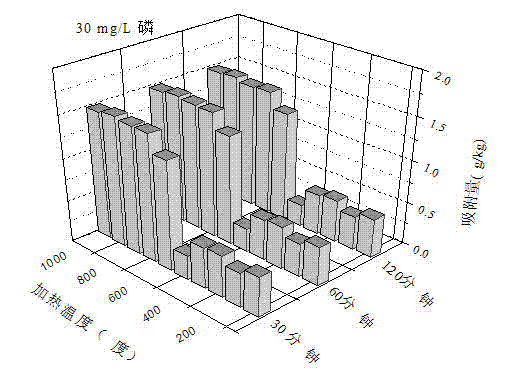

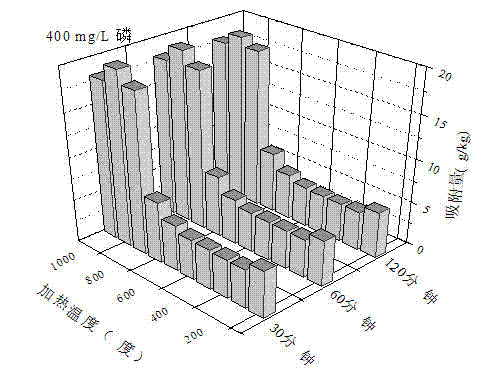

[0030] Take a certain amount of undisturbed calcium-rich sepiolite, grind it mechanically to less than 100 mesh, and dry it at 105°C to constant weight, and then heat it at a certain temperature (200°C-1000°C, every interval of 100°C is a gradient). The time (0.5h, 1h, and 2h) was modified by heating to prepare calcium-based sepiolite phosphorus adsorbent.

[0031] Take 0.5g of the adsorption material obtained under the above different treatment conditions, add 50ml centrifuge tubes filled with 25ml low (0.5 mg / L), medium (30mg / L) and high (400mg / L) concentration phosphorus-containing wastewater After shaking (160rmp) at constant temperature (25°C) for 12 hours, centrifuge the solution, measure the residual phosphorus concentration in the supernatant, calculate the phosphorus removal rate, and determine the optimum modification temperature and time based on the above results.

[0032] The experimen...

Embodiment 2

[0033] Example 2 Comparison of Phosphorus Removal Effects Before and After Thermal Modification of Calcium-rich Sepiolite

[0034]Take 0.5 g of the modified and untreated calcium-rich sepiolite prepared in Example 1 and place them in 25 ml of phosphorus-containing wastewater of different concentrations (0.05 mg / L-600 mg / L) respectively. In a centrifuge tube, shake (160rmp) at a constant temperature (25°C) for 12 hours, then centrifuge the solution, measure the residual phosphorus concentration in the supernatant, and calculate the phosphorus removal rate. The result is as Figure 2a and Figure 2b shown.

[0035] Figure 2a and Figure 2b It shows that the calcium-rich sepiolite adsorbent of the present invention removes phosphorus, and for low concentration sewage (0.05 mg / L≤phosphorus concentration≤1 mg / L), the phosphorus removal rate is 80.0%~98.8%; for medium and high concentration sewage (1mg / L / L<phosphorus concentration≤600mg / L), the phosphorus removal rate is 99.0...

Embodiment 3

[0036] Example 3 The actual removal effect of modified calcium-rich sepiolite on phosphorus in lake water

[0037] Take 2 g of modified and untreated calcium-rich sepiolite prepared in Example 1 and put it into 1 L of Chaohu Lake water with a phosphorus concentration of 0.054 (dosing amount is 2 g / L), fully shake, and Take water samples for filtration at 5 minutes, 30 minutes and 60 minutes, analyze the phosphorus concentration, and calculate the phosphorus removal rate. The result is as image 3 shown.

[0038] image 3 The results show that the phosphorus removal rate of the calcium-rich sepiolite adsorbent treated at 900 ° C is 88.9% in 5 minutes, 96.8% in 30 minutes, and 97.6% in 60 minutes. In contrast, the phosphorus removal rate of untreated calcium-rich sepiolite was 45.4% in 5 minutes, 52.1% in 30 minutes, and 55.6% in 60 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com