Metallic-organic gel matrix solid-phase microextraction head with multiple levels of hole channels and preparation method thereof

A technology of organic gel and matrix solid phase, applied in chemical instruments and methods, other chemical processes, ion exchange, etc., can solve problems such as limited application range, poor selectivity, and high price, and achieve the effect of increasing enrichment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 0.6750 g of aluminum nitrate hexahydrate, weigh 0.1952 g of terephthalic acid, dissolve in 4 mL of ethanol, place in a 10 mL airtight bottle or a 15 mL reaction kettle, and place the airtight bottle or reaction kettle in an oven or After heating to 80°C in a drying oven for 4 hours, a metal-organic gel was obtained. The obtained product is further placed in an oven or a dry box for aging at 80° C. for 2 days. The resulting gel is wrapped with filter paper, put into a Soxhlet extractor, put the metal-organic gel wrapped by filter paper into a supercritical kettle, and carry out supercritical carbon dioxide drying. The drying time is 24 hours, and the aluminum nitrate Calculate, product yield is 90%.

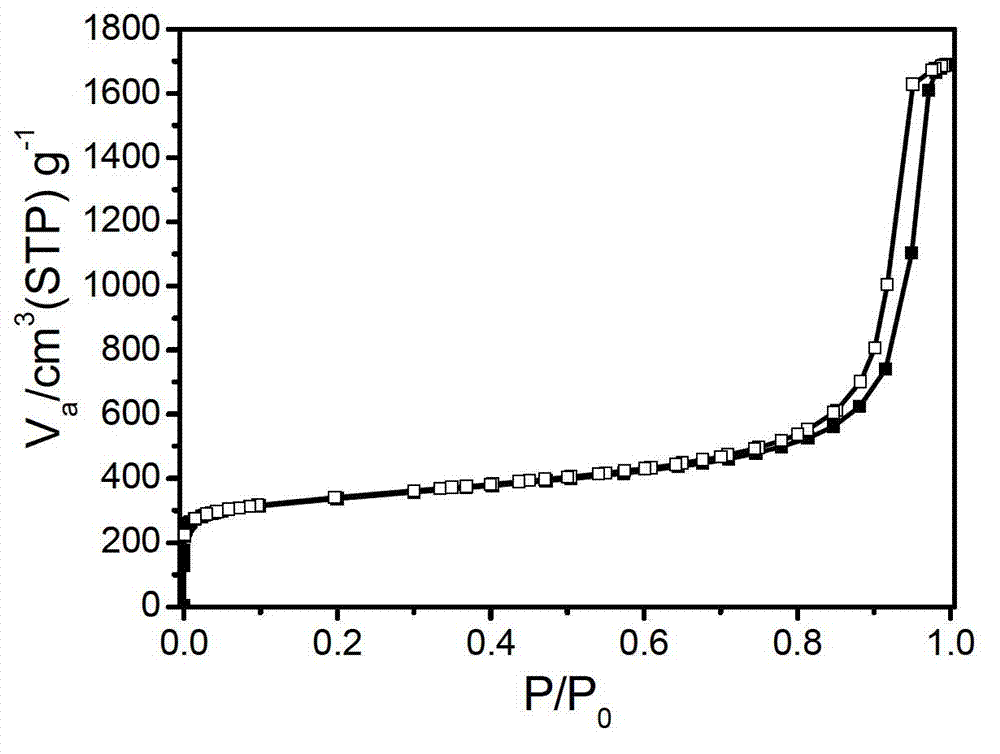

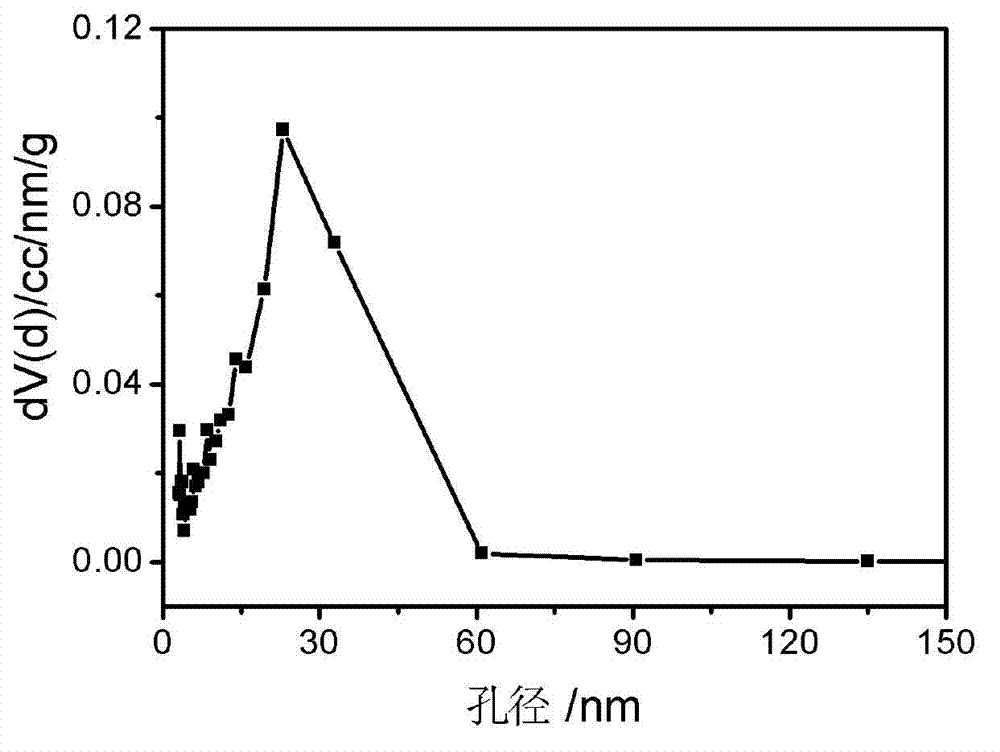

[0036] Such as figure 1 The low-temperature nitrogen adsorption-desorption isotherm of the product obtained in Example 1 is given. X-axis is P / P 0 , the Y axis is the volume (cm 3 / g). The pretreatment condition for adsorption was vacuum drying at 80°C for 16 ho...

Embodiment 2

[0047] Weigh 0.3375 g of aluminum nitrate hexahydrate, weigh 0.1260 g of trimesic acid, dissolve in 12 mL of ethanol, place in a 10 mL airtight bottle or a 15 mL reaction kettle, and place the airtight bottle or reaction kettle in an oven or After heating to 80°C in a drying oven for 4 hours, a metal-organic gel was obtained. The obtained product was further aged in an oven at 80° C. for 2 days. The resulting gel is wrapped with filter paper, put into a Soxhlet extractor, put the metal-organic gel wrapped by filter paper into a supercritical kettle, and carry out supercritical carbon dioxide drying. The drying time is 24 hours, and the aluminum nitrate Calculate, product yield is 90%. An aerogel is thus obtained.

[0048] Figure 5 The low-temperature nitrogen adsorption-desorption isotherms of the airgel products obtained in Examples 2-4 are given. X-axis is P / P 0 , the Y axis is the volume (cm 3 / g). The pretreatment condition for adsorption was vacuum drying at 80°C ...

Embodiment 3

[0063] Weigh 0.3375 g of aluminum nitrate hexahydrate, weigh 0.1260 g of trimesic acid, dissolve in 8 mL of ethanol, place in a 10 mL airtight bottle or a 15 mL reactor, and place the airtight bottle or reactor in an oven After heating to 80°C for 4 hours, a metal-organic gel was obtained. The obtained product is further placed in an oven or a dry box for aging at 80° C. for 2 days. The resulting gel is wrapped with filter paper, put into a Soxhlet extractor, put the metal-organic gel wrapped by filter paper into a supercritical kettle, and carry out supercritical carbon dioxide drying. The drying time is 24 hours, and the aluminum nitrate Calculate, product yield is 90%. An aerogel is thus obtained.

[0064] Figure 5 The low-temperature nitrogen adsorption-desorption isotherms of the airgel products obtained in Examples 2-4 are given. X-axis is P / P 0 , the Y axis is the volume (cm 3 / g). The pretreatment condition for adsorption was vacuum drying at 80°C for 16 hours....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com