Reaction type antistatic agent, preparation method and durable antistatic polyurethane material

An antistatic agent and reactive technology, applied in the field of polymer materials and its preparation, can solve the problems of high volume resistance and unsustainable antistatic effect, and achieve the effect of good durability and good dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

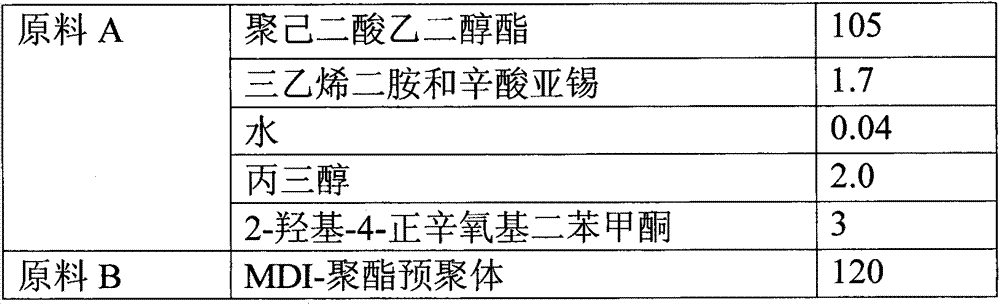

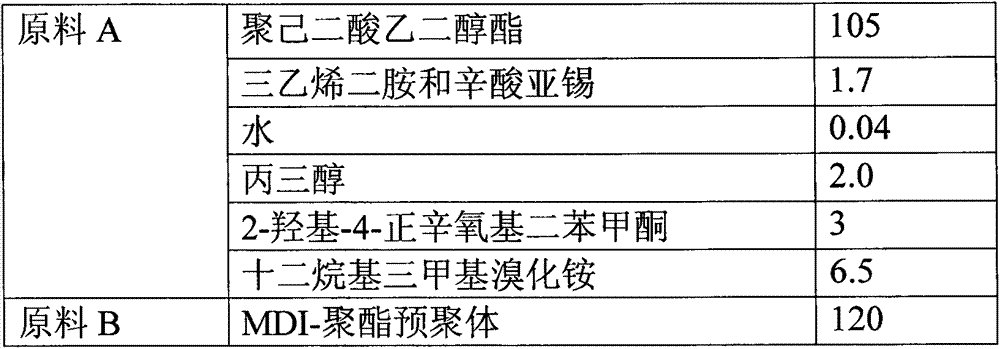

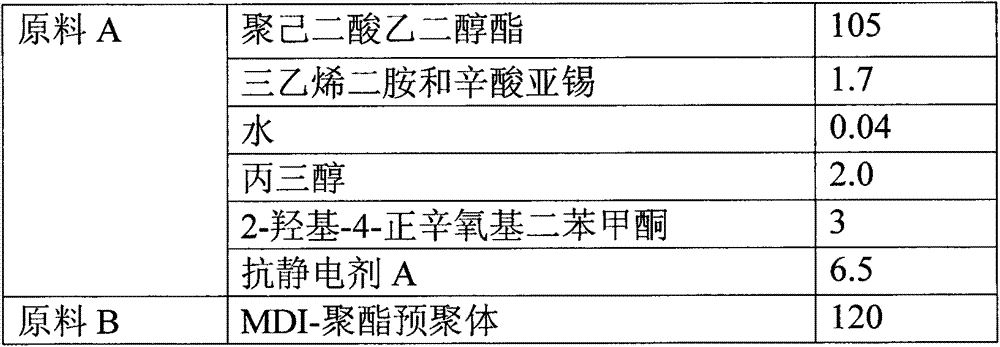

Examples

Embodiment A

[0028] Synthesis of antistatic agent ASA-1

[0029] (1) In a 500mL dry three-necked flask, add 40g (0.10mol) polyethylene glycol (PEG, molecular weight 400), 64.5g (0.7mol) of epichlorohydrin, 50% (mass fraction) sodium hydroxide aqueous solution 24g (0.3mol), catalyst tetrabutylammonium bromide 1.60g (0.005mol), dichloromethane 40ml warmed to 50 ℃ reflux reaction, then vigorously stirred for 4h, cooled to room temperature, suction filtration. Add anhydrous sodium sulfate to dry, and filter with suction. The filtrate was distilled to remove the solvent dichloromethane and unreacted epichlorohydrin to obtain a colorless viscous crude product. The above products were directly used in the next reaction without further purification.

[0030] (2) In a 250 mL dry three-necked flask, add all the crude products synthesized above, 19.2 g (0.2 mol) of trimethylamine hydrochloride, and 30 mL of ethanol, and stir at 30° C. for 3 h. The solvent was distilled off to get the crude product...

Embodiment B

[0032] Synthesis of antistatic agent ASA-2

[0033] (1) In a 500mL dry three-necked flask, add 100g (0.10mol) polyethylene glycol (PEG, molecular weight 1000), 64.5g (0.7mol) of epichlorohydrin, 50% (mass fraction) sodium hydroxide aqueous solution 24g (0.3mol), catalyst tetrabutylammonium bromide 1.60g (0.005mol), dichloromethane 40ml warmed to 50 ℃ reflux reaction, then vigorously stirred for 4h, cooled to room temperature, suction filtration. Add anhydrous sodium sulfate to dry, and filter with suction. The filtrate was distilled to remove the solvent dichloromethane and unreacted epichlorohydrin to obtain a colorless viscous crude product. The above products were directly used in the next reaction without further purification.

[0034] (2) In a 250 mL dry three-necked flask, add all the crude products synthesized above, 19.2 g (0.2 mol) of trimethylamine hydrochloride, and 30 mL of ethanol, and stir at 30° C. for 3 h. The solvent was distilled off to obtain a crude prod...

Embodiment C

[0036] Synthesis of antistatic agent ASA-3

[0037] (1) In a 500mL dry three-necked flask, add 150g (0.10mol) polyethylene glycol (PEG, molecular weight 1500), 64.5g (0.7mol) of epichlorohydrin, 50% (mass fraction) sodium hydroxide aqueous solution 24g (0.3mol), catalyst tetrabutylammonium bromide 1.60g (0.005mol), dichloromethane 40ml warmed to 50 ℃ reflux reaction, then vigorously stirred for 4h, cooled to room temperature, suction filtration. Add anhydrous sodium sulfate to dry, and filter with suction. The filtrate was distilled to remove the solvent dichloromethane and unreacted epichlorohydrin to obtain a colorless viscous crude product. The above products were directly used in the next reaction without further purification.

[0038] (2) In a 250 mL dry three-necked flask, add all the crude products synthesized above, 19.2 g (0.2 mol) of trimethylamine hydrochloride, and 30 mL of ethanol, and stir at 30° C. for 3 h. The solvent was distilled off to obtain a crude prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com