Oxidation-resistant transformer oil

A transformer oil and anti-oxidation technology, which is applied in the field of transformer oil, can solve the problems of transformers not running normally, affecting the reliability of the power grid, turbidity, etc., and achieve the effect of convenient production, low cost, and good thermal oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

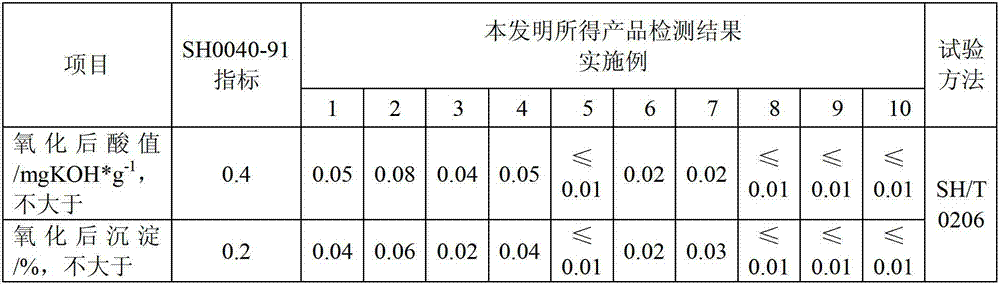

Examples

Embodiment 1

[0019] Contains by weight percentage:

[0020] 2,6-di-tert-butyl-p-cresol 0.2%,

[0021] 2-(2′-hydroxy-5′-methylphenyl)benzotriazole 0.5‰

[0022] Benzotriazole 20ppm

[0023] Surplus transformer base oil.

[0024] Prepare according to the method provided by the present invention.

Embodiment 2

[0026] Contains by weight percentage:

[0027] 2,6-di-tert-butyl-p-cresol 1.5%,

[0028] 2-(2′-hydroxy-5′-methylphenyl)benzotriazole 0.2‰

[0029] Benzotriazole 5ppm

[0030] Surplus transformer base oil.

[0031] Prepare according to the method provided by the present invention. .

Embodiment 3

[0033] Contains by weight percentage:

[0034] 2,6-di-tert-butyl-p-cresol 0.5%,

[0035] 2-(2'-Hydroxy-5'-methylphenyl)benzotriazole 0.1%

[0036] Benzotriazole 100ppm

[0037] Surplus transformer base oil.

[0038] Prepare according to the method provided by the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com