Micro hemispherical resonator gyro and preparation method thereof

A technology of hemispherical resonant gyroscope and hemispherical resonator, which is applied to gyroscope/steering sensing equipment, gyroscopic effect for speed measurement, measurement device and other directions, can solve the problems of difficult detection of sensitive signals, too large supporting surface, large working area, etc. Achieve the effect of overcoming too small working area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

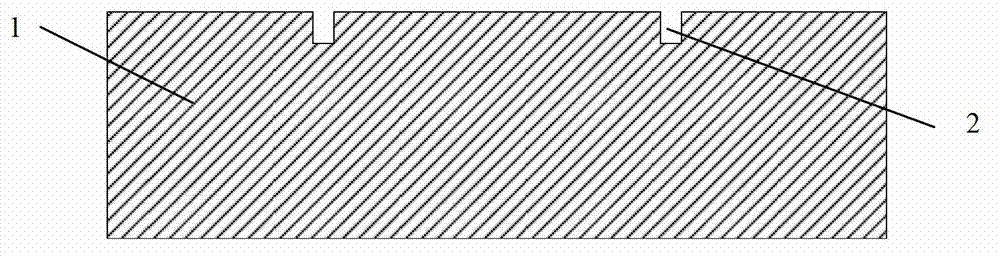

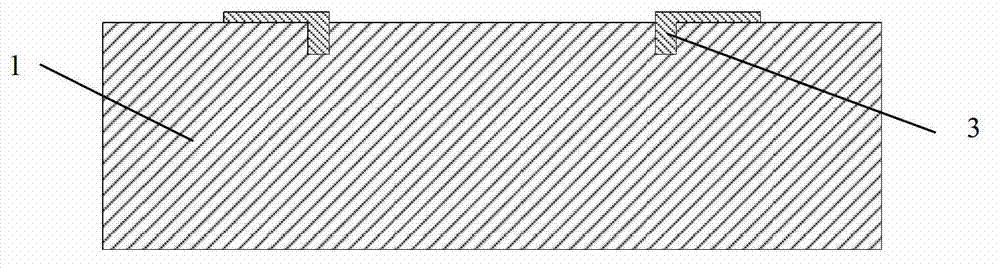

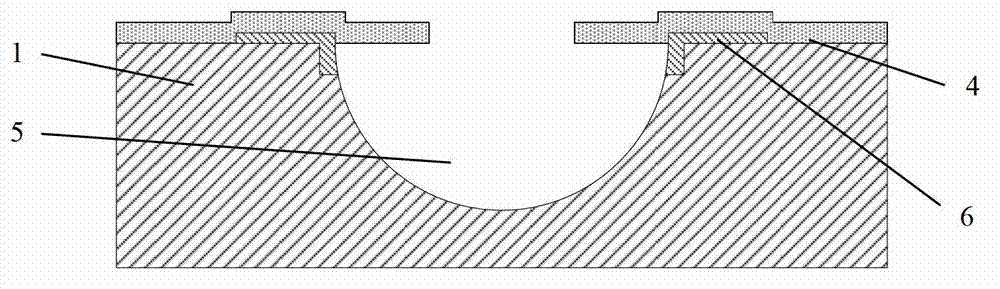

[0021] In this example, a kind of figure 2 The miniature hemispherical resonator gyroscope shown, the gyroscope includes a silicon body 1 located on an insulating layer 8, a hemispherical resonator cavity 5 is arranged on the silicon body 1; a shell-shaped hemispherical resonator 9 is suspended on the silicon body through a support on the body 1, and the hemispherical resonator 9 is concentric with the hemispherical resonator cavity 5 on the silicon body 1; The electrical insulation between them is through the insulating layer 8; the electrical signal of the hemispherical resonator 9 communicates with the signal loading electrode 11 placed under the insulating layer 8 through the support body 10; the end face of the silicon body 1 is evenly distributed along the circumference of the hemispherical resonator cavity 5 One set of driving electrodes 12 and four sets of sensitive electrodes 13 . It is characterized in that: the support body 10 is a fan-shaped ring structure formed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com