Silver conductor paste for semiconductor ceramic capacitor electrode and preparation method of silver conductor paste

A technology of ceramic capacitors and silver conductor paste, which is applied in the direction of fixed capacitor electrodes, conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, etc., can solve the problems of capacitor capacity reduction, etc., to improve capacitance, disperse Good performance and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

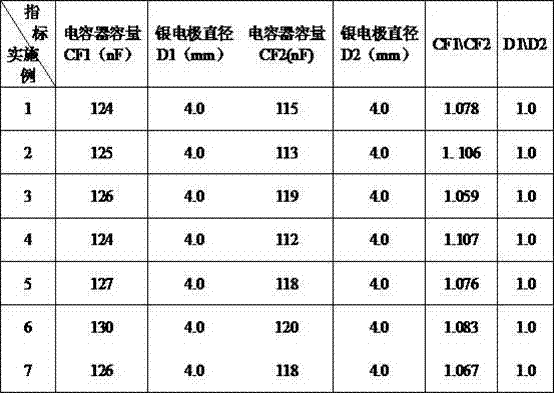

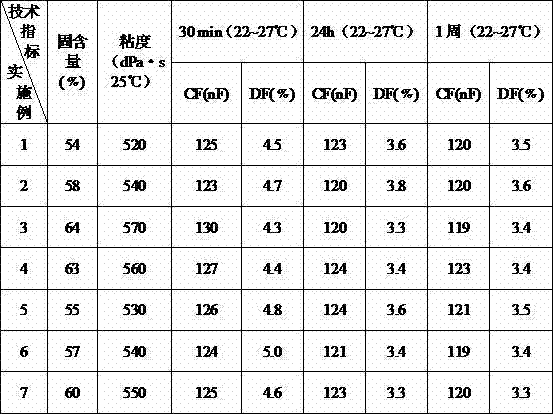

Examples

Embodiment 1

[0028] The steps of the preparation method of the silver conductor paste for the semiconductor ceramic capacitor electrode of the present embodiment are as follows:

[0029] S1. Determine the material proportion of the silver conductor paste for the semiconductor ceramic capacitor electrode, weigh 470g, an organic carrier with a viscosity of 170dPa s, and place 25 to 30% of the total amount of the organic carrier in the batching bucket;

[0030] S2. Taking the organic carrier as the basis of measurement, weigh 500g of silver powder with a particle size of 0.30μm, 3.4g of other metal powders with a particle size of 3.0μm, 26g of inorganic additives and 0.6g of glass powder, and put the weighed materials into the above In the batching bucket and mix well;

[0031] S3. Rolling the material obtained in step S2, the controlled rolling time is 20-30min per 10kg of rolling;

[0032]S4. When the fineness of the material obtained in step S3 reaches below 10 μm, put the material into t...

Embodiment 2

[0040] The steps of the preparation method of the silver conductor paste for the semiconductor ceramic capacitor electrode of the present embodiment are as follows:

[0041] S1. Determine the material ratio of the silver conductor paste for the semiconductor ceramic capacitor electrode, weigh 410g, the organic carrier with a viscosity of 150dPa s, and place 25 to 30% of the total amount of the organic carrier in the batching bucket;

[0042] S2. Taking the organic carrier as the basis of measurement, weigh 550g of silver powder with a particle size of 0.55μm, 11.3g of other metal powders with a particle size of 3.4μm, 28g of inorganic additives and 0.7g of glass powder, and put the weighed materials into the above-mentioned In the batching bucket and mix well;

[0043] S3. Rolling the material obtained in step S2, the controlled rolling time is 20-30min per 10kg of rolling;

[0044] S4. When the fineness of the material obtained in step S3 reaches below 10 μm, put the materia...

Embodiment 3

[0052] The steps of the preparation method of the silver conductor paste for the semiconductor ceramic capacitor electrode of the present embodiment are as follows:

[0053] S1. Determine the material proportion of the silver conductor paste for the semiconductor ceramic capacitor electrode, weigh 360g, an organic carrier with a viscosity of 70dPa s, and place 25 to 30% of the total amount of the organic carrier in the batching bucket;

[0054] S2. Taking the organic carrier as the measurement basis, weigh 600g of silver powder with a particle size of 0.86μm, 18g of other metal powders with a particle size of 3.8μm, 21.2g of inorganic additives and 0.8g of glass powder, and put the weighed materials into the above-mentioned In the batching bucket and mix well;

[0055] S3. Rolling the material obtained in step S2, the controlled rolling time is 20-30min per 10kg of rolling;

[0056] S4. When the fineness of the material obtained in step S3 reaches below 10 μm, put the materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com