Low-pressure catalytic thermal-hydrolysis sludge treatment method and application thereof

A technology of catalytic thermal hydrolysis and treatment method, applied in the field of sludge treatment, can solve the problems of high operating cost and investment cost, strict equipment requirements, low treatment efficiency, etc., achieve energy consumption and equipment requirements control, improve dehydration performance, Effect of exhaust gas treatment load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

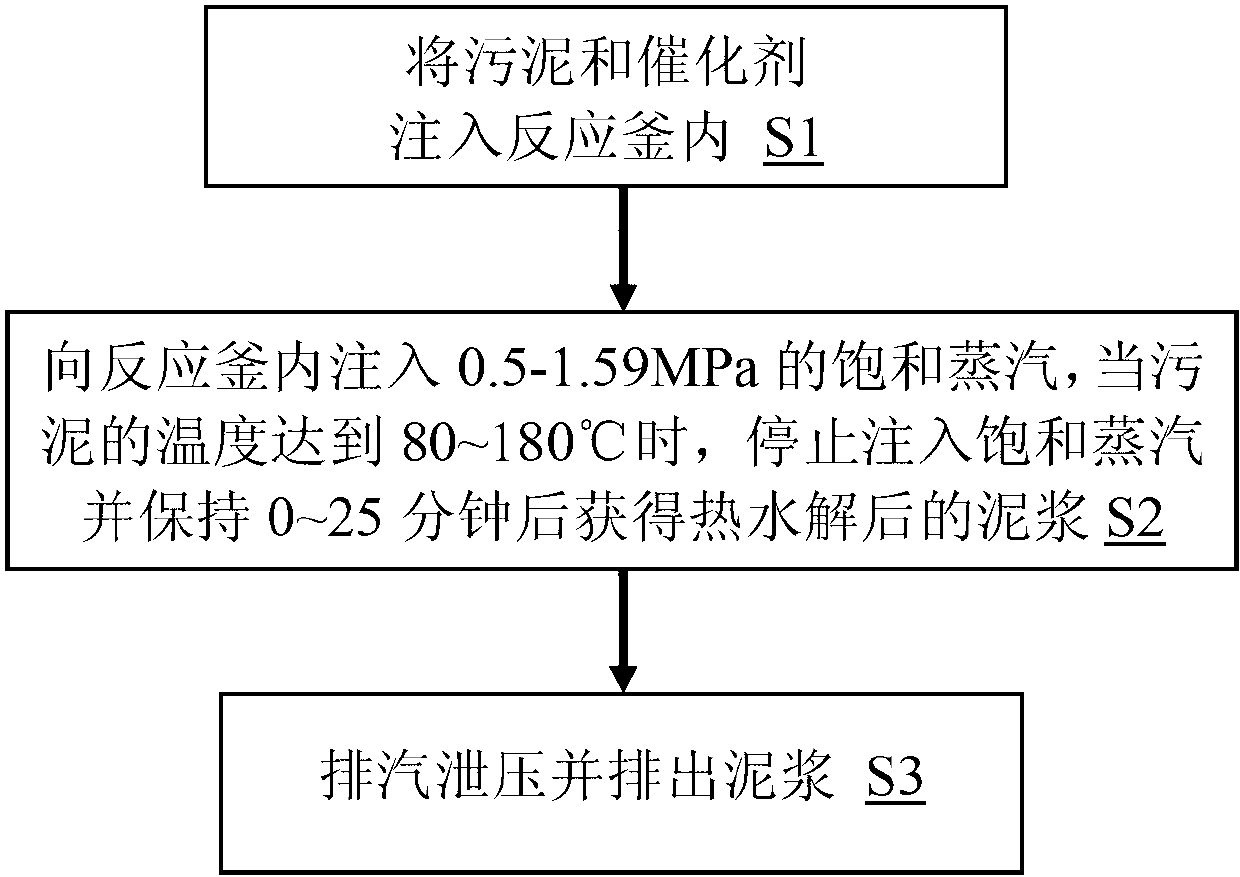

Method used

Image

Examples

Embodiment 1

[0029] Inject 50kg of sodium carbonate and 1 ton of sludge with a water content of 90-97% into the reactor, close the feed port of the reactor, and start the stirring device in the reactor; inject 0.5-0.8MPa of Saturated steam, heat the sludge mixed with sodium carbonate in the reactor; detect the real-time temperature of the sludge in the lower part of the reactor, when the temperature of the sludge reaches 140°C, stop injecting saturated steam and keep it for 20-25 minutes; then open the drain The pressure valve starts to exhaust steam and relieve pressure. When the pressure in the reactor drops below 0.05MPa, the discharge valve is opened to discharge the mud obtained by thermal hydrolysis treatment. At this point, the low-pressure catalytic thermal hydrolysis treatment of the sludge with a water content of 90-97% is completed.

[0030]After the discharged mud is cooled, it is dehydrated to obtain a dewatered liquid and a dewatered cake with a water content of 55-60%.

Embodiment 2

[0032] Inject 30kg of sodium hydroxide and 1 ton of sludge with a water content of 85-89% into the reactor, close the feed port of the reactor, and start the stirring device in the reactor, stirring at a constant speed for 1 minute to mix the sodium hydroxide with the sludge Uniform; inject saturated steam of 0.9-1.1MPa from the upper and lower parts of the reactor to heat the sludge mixed with sodium hydroxide in the reactor; detect the real-time temperature of the sludge in the middle of the reactor, when the sludge temperature reaches 160°C , stop injecting saturated steam and keep it for 15-20 minutes; then open the pressure relief valve to start steam and pressure relief, and when the pressure in the reactor drops below 0.05MPa, open the discharge valve to discharge the mud obtained by thermal hydrolysis treatment. At this point, the low-pressure catalytic thermal hydrolysis treatment of the sludge with a water content of 85-89% is completed.

[0033] After the discharged...

Embodiment 3

[0035] Inject 5kg of calcium hydroxide, 30kg of potassium hydroxide and 1 ton of sludge with a water content of 80-85% into the reactor, close the feed port of the reactor, start the stirring device in the reactor, and stir at a constant speed for 3 minutes to make the hydrogen Calcium oxide and potassium hydroxide are mixed evenly with the sludge; at the same time, 1.2-1.4MPa saturated steam is injected from the upper and lower parts of the reactor to heat the sludge mixed with calcium hydroxide and potassium hydroxide in the reactor; The real-time temperature of the sludge in the middle of the kettle. When the temperature of the sludge reaches 130°C, stop injecting saturated steam and keep it for 10-15 minutes; then open the pressure relief valve to start exhausting steam and pressure relief. When the pressure in the reactor drops below 0.05MPa Open the discharge valve at the same time to discharge the mud obtained by thermal hydrolysis treatment. At this point, the low-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com