Power station boiler combustor based on pulverized coal classified pre-burning-pyrolysis

A power station boiler and burner technology, which is applied in the direction of burners, burners, and combustion methods for burning powder fuels, can solve problems such as low furnace temperature, low concentration of secondary air pulverized coal, and violation of economic benefits, and achieve structural and The system is simple, the operation cost is reduced, and the operation efficiency is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

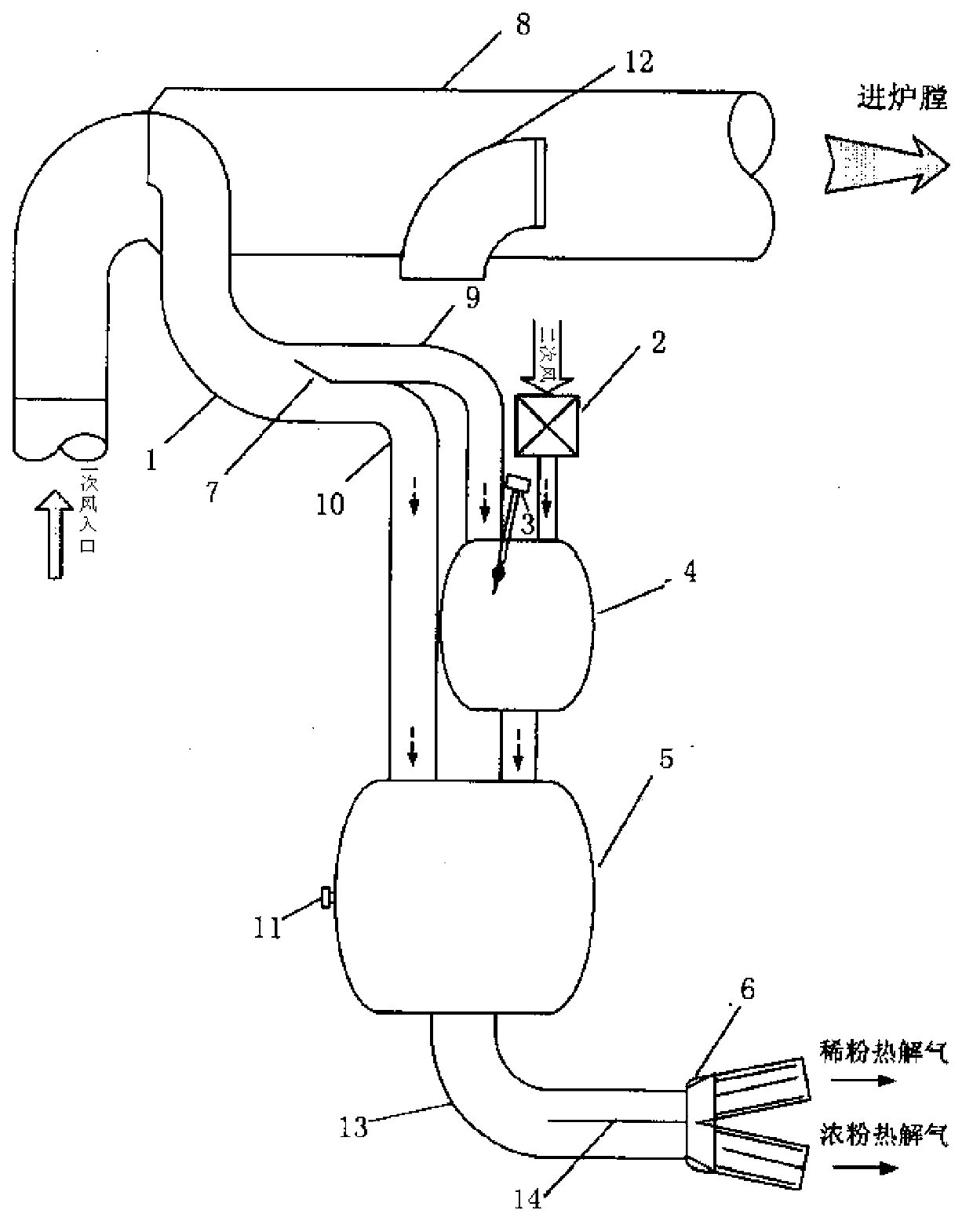

[0015] The invention proposes a power plant boiler burner based on coal powder graded precombustion-pyrolysis. Be described below in conjunction with accompanying drawing.

[0016] Such as figure 1 As shown, the power station boiler burner based on coal powder graded precombustion-pyrolysis is composed of a main burner 8, an air duct 1, a pre-combustion chamber 4, a pyrolysis chamber 5 and a pyrolysis gas nozzle 6; in the main burner 8 An air induction pipe 1 is arranged at the entrance elbow, and the air induction pipe 1 is composed of two sections of straight pipes and one section of elbow pipe. Concentrated pulverized coal pipeline 10; the front section of the partition baffle 7 is designed to be swingable, and the rear end is a straight plate with a maximum swing angle of 60° O , the pulverized coal flow rate entering the dense pulverized coal pipeline 10 can be changed according to the requirements of different working conditions. The thin pulverized coal pipeline 9 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com