Etching fluid composition and etching method

A technology of etching solution and composition, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of increased cost, reduced output, complicated processes, etc., and achieve the effect of efficient etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

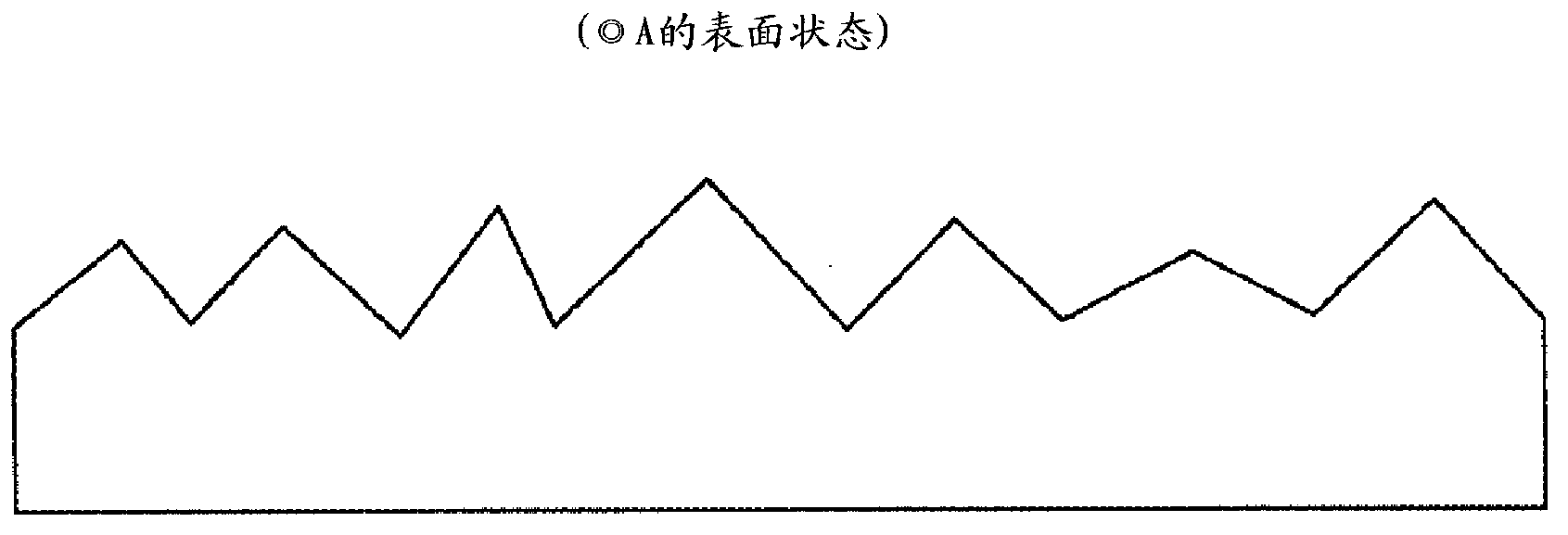

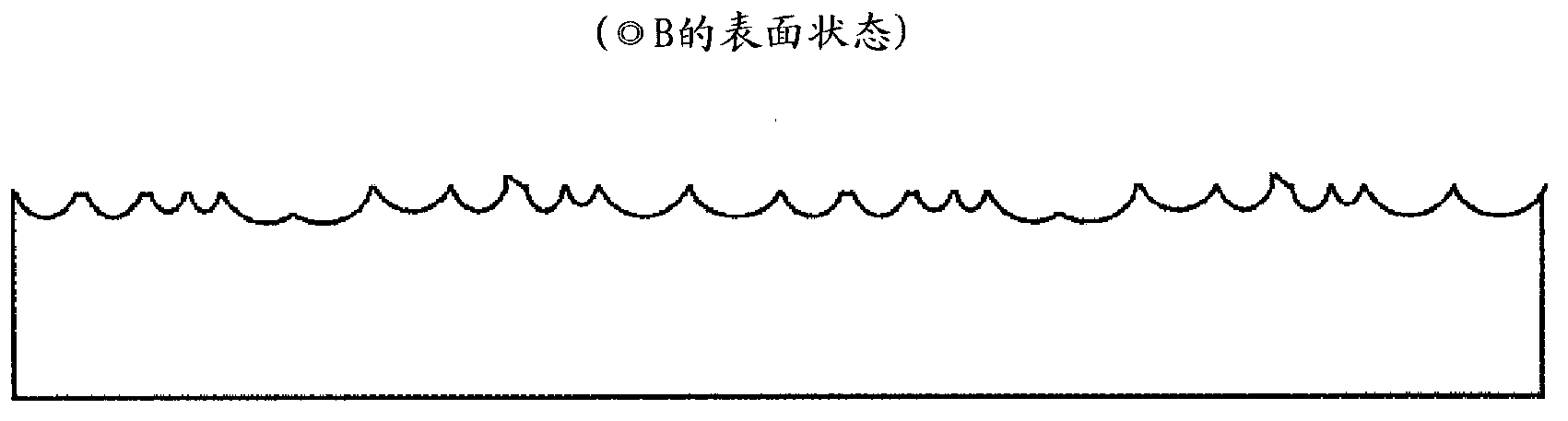

Image

Examples

Embodiment

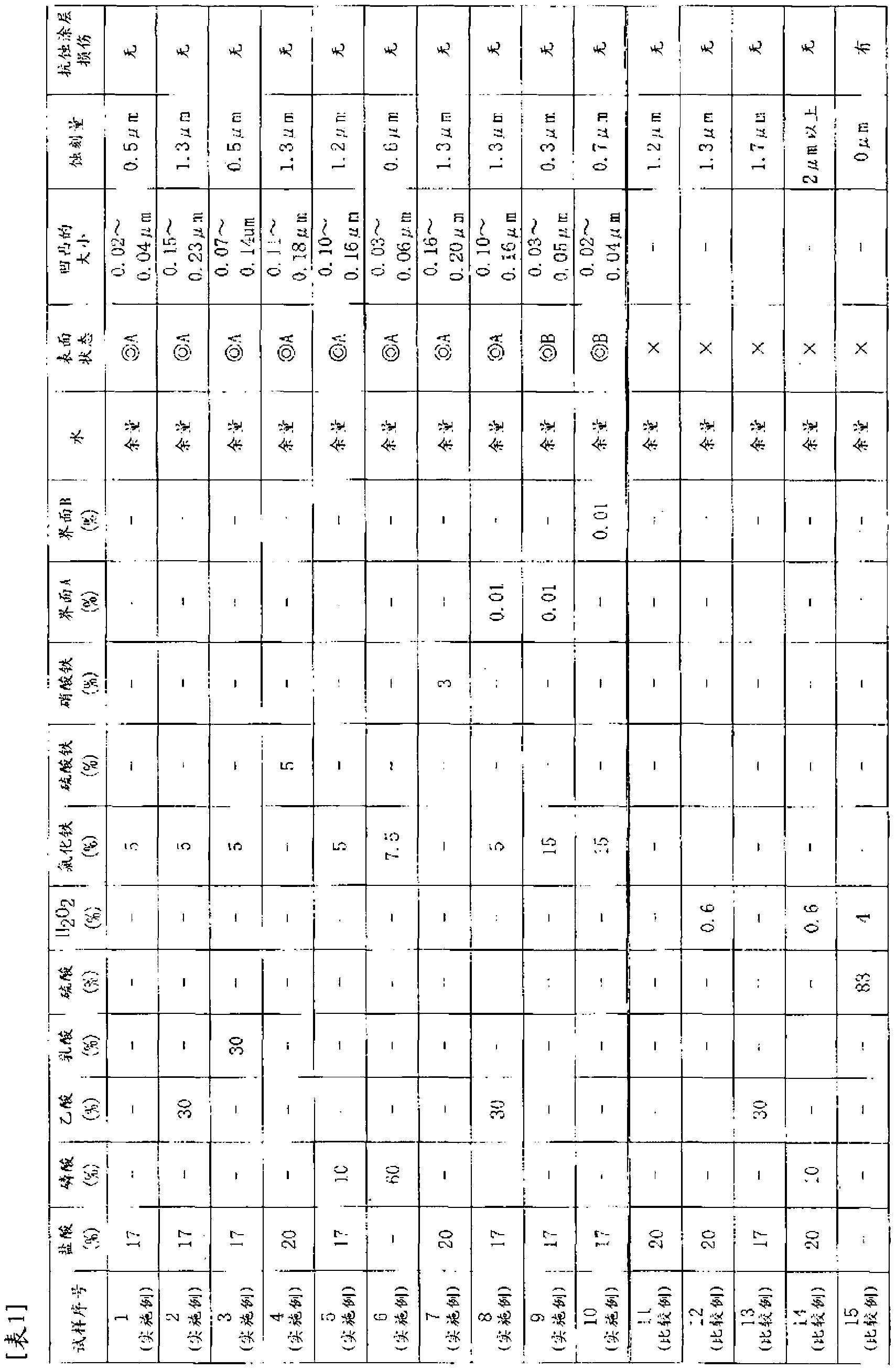

[0069] Hereinafter, the present invention will be described more specifically by way of examples, but the present invention is not limited by these examples.

[0070] [Preparation of etching solution composition (sample)]

[0071] Prepare hydrochloric acid, phosphoric acid, acetic acid, lactic acid, sulfuric acid, hydrogen peroxide (H 2 o 2 ), ferric chloride, ferric sulfate, ferric nitrate, perfluoroalkyl amine oxide (amphoteric surfactant), perfluoroalkyl sulfonic acid (anionic surfactant) and other raw materials.

[0072] These raw materials were weighed to have the compositions shown in Table 1 and dissolved in water to prepare samples (etching liquid compositions) of sample numbers 1 to 15 in Table 1.

[0073] It should be noted that the samples of sample numbers 1 to 10 are samples of examples having the requirements of the present invention, and the samples of sample numbers 11 to 15 are samples of comparative examples not having the requirements of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com