Method and device for improving wettability of brazing filler metal and method and device thereof for detection experiments

An experimental method and wettability technology, applied in the direction of vibrating fluid, welding equipment, metal processing equipment, etc., can solve the problems of poor temperature uniformity in the heating environment, poor secondary development of experimental equipment, and single variety of electrostatic field power supply. To achieve the effect of improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

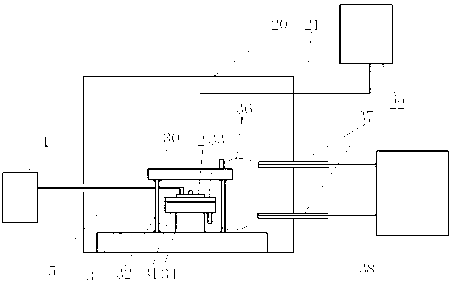

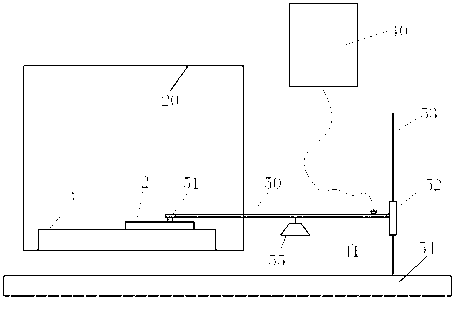

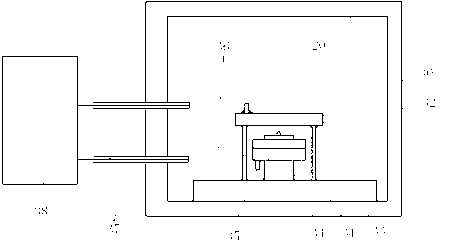

Method used

Image

Examples

specific Embodiment 2

[0060] The specific embodiment 2 of the detection experimental method of improving solder wettability of the present invention comprises the following steps:

[0061] a) Preparation before welding: select a 40mm×40mm×1.8mm copper plate as the base material, and use 400#~800# sandpaper to polish the surface of the base metal to be welded, soak it in acetone, clean it, and dry it for later use; put Sn2.5Ag0. 7Cu0.1RE brazing material is made into 0.2±0.01g particles, soaked in acetone, cleaned, dried and then used for later use; the positive DC high voltage output terminal of the electrostatic field power supply with the lower electrode plate connected to the electrostatic field power supply, and the upper electrode plate connected to the electrostatic field power supply The connection method of the ground terminal.

[0062] b) Heating the base metal and brazing material: After the heating furnace is energized and heated to 270°C, place 0.2±0.01g of brazing material in the cente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com