HMCM-49 molecular sieve production method

A HMCM-49, production method technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of incomplete recovery of hexamethyleneimine, direct discharge of hexamethyleneimine waste water, etc., and save equipment investment , the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

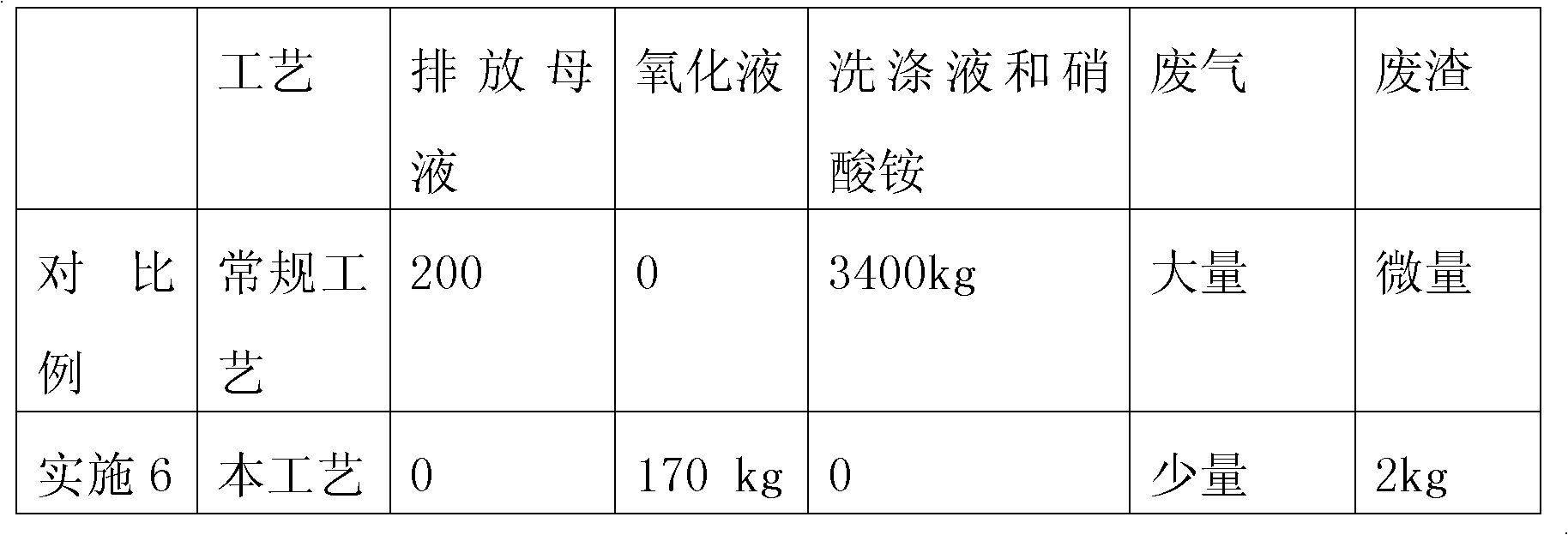

Examples

Embodiment 1

[0013] Add 100kg of desalted water, 110kg of mother liquor, 11kg of sodium metaaluminate or sodium aluminate, 250kg of silica sol with a mass content of 26%, 35kg of hexamethyleneimine and 2kg of NaMCM-49 molecular sieves in sequence, and fully stir to carry out Batching, gelling and crystallization; at 40°C, enter the plate and frame filter press to separate the mother liquor. The mother liquor is poured into the mother liquor storage tank with a mother liquor pump; the filter cake is sent to the oxidation tank, and 90kg of desalted water is added, and 15kg of hydrogen peroxide with a mass content of 30% is added at 65°C, and oxidized for 5 hours; after the oxidation is completed, it is sent to a plate and frame filter press , 80kg of filtrate is discharged waste water; the filter cake is sent to the oven and dried at 120°C for 6 hours; after drying, it is roasted at 550°C for 8 hours to produce a small amount of waste gas; The aqueous citric acid solution with a mass content...

Embodiment 2

[0015] 70kg of desalted water, 150kg of mother liquor, 11Kg of sodium metaaluminate or sodium aluminate, and 250kg of silica sol with a mass content of 26%. 35kg of hexamethyleneimine and 2kg of NaMCM-49 molecular sieve are added in turn, and fully stirred for batching, gelation and crystallization; at 60°C, enter the plate and frame filter press to separate the mother liquor, and use the mother liquor pump to pump the mother liquor Put the filter cake into the mother liquor storage tank; send the filter cake to the oxidation tank, add 120kg of desalted water, add 20kg of hydrogen peroxide with a mass content of 30% at 65°C, and oxidize for 4 hours; Drainage water; the filter cake is sent to an oven and dried at 120°C for 10 hours; roasted at 540°C for 20 hours to produce a small amount of waste gas; after cooling, put it into a pulping tank and add citric acid aqueous solution with a mass content of 6% , sent to the rotary vane dynamic filter press, washed for 30min, and test...

Embodiment 3

[0017] Add 100kg of desalted water, 110kg of mother liquor, 11Kg of sodium metaaluminate or sodium aluminate, 250kg of silica sol with a mass content of 26%, 35kg of hexamethyleneimine and 2kg of NaMCM-49 molecular sieves in sequence, and fully stir to carry out Batching, gelling and crystallization; at 50°C, enter the plate and frame filter press to separate the mother liquor. The mother liquor is poured into the mother liquor storage tank with a mother liquor pump; the filter cake is sent to the oxidation tank, and 200kg of desalted water is added, and at 65°C, 30kg of hydrogen peroxide with a mass content of 30% is added, and oxidized for 5 hours; after the oxidation is completed, it is sent to a plate and frame filter press , 160kg of filtrate is discharged waste water; the filter cake is sent into the oven and dried for 6h at 120°C; roasted for 15h at 560°C to produce a small amount of waste gas; after cooling, put it into the pulping tank and add 15 % citric acid aqueous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com