Ceramic base copper clad laminate and production method thereof

A technology of ceramic copper clad laminates and ceramic substrates, which is applied in circuit substrate materials, multilayer circuit manufacturing, printed circuit components, etc., can solve the problem that adhesion is difficult to guarantee, the sputtered copper plating layer is not dense enough, and the peeling resistance is not enough. requirements and other issues to achieve the effect of reducing product costs and improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

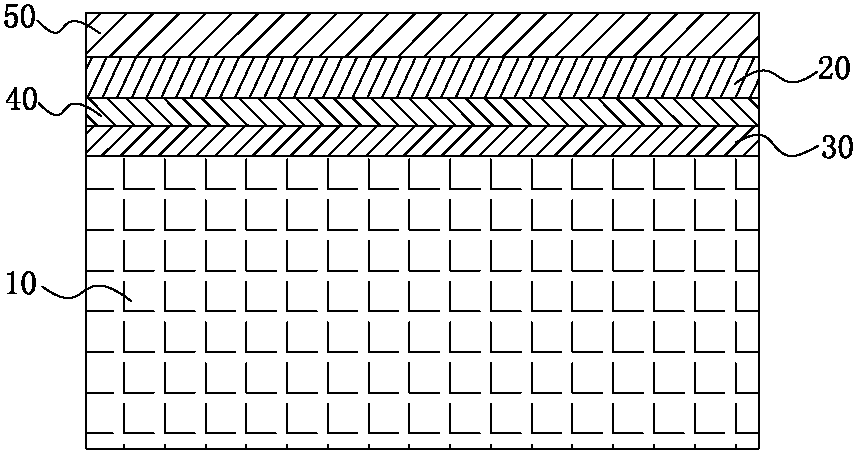

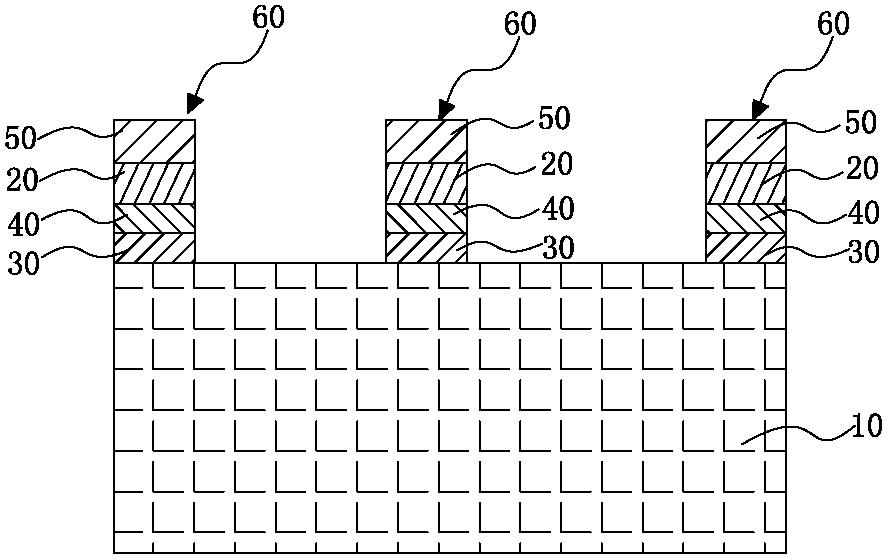

[0026] Please refer to figure 2 As shown, it shows the specific structure of a preferred embodiment of the present invention: a ceramic copper clad laminate, including a ceramic substrate 10, on which a titanium layer 20, a nickel layer 30 and a copper layer 40 are sequentially arranged, The titanium layer 20 is attached to the ceramic substrate 10, the nickel layer 30 is attached to the titanium layer 20, and the copper layer 40 is attached to the nickel layer 30; the thickness of the titanium layer 20 is 30-100 nanometers, and the nickel layer The thickness of 30 is 30-100 nanometers, and the thickness of the copper layer 40 is 50-150 nanometers; a thickened copper layer 50 is electroplated on the copper layer 40 .

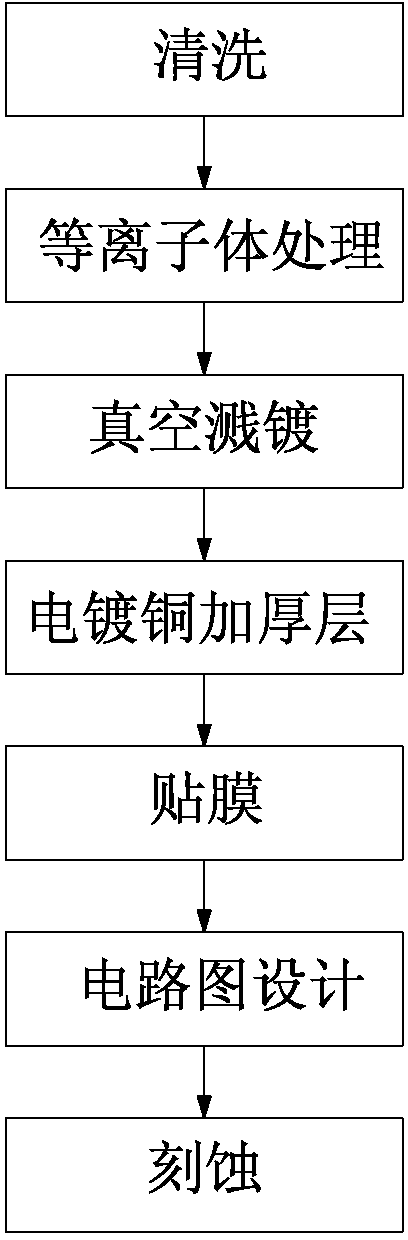

[0027] Such as figure 1 Shown, a kind of preparation method of ceramic copper clad laminate and circuit board thereof comprises the following steps:

[0028] (1) Cleaning: cleaning the ceramic substrate 10 with alcohol, and then baking at 200° C. for 60 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com