Treatment method for exhaust gases in production of profenofos

A treatment method, profenofos technology, applied in separation methods, chemical instruments and methods, steam condensation, etc., can solve problems such as poor vacuum power and poor absorption efficiency, so as to improve safety, eliminate potential safety hazards, and ensure absorption effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

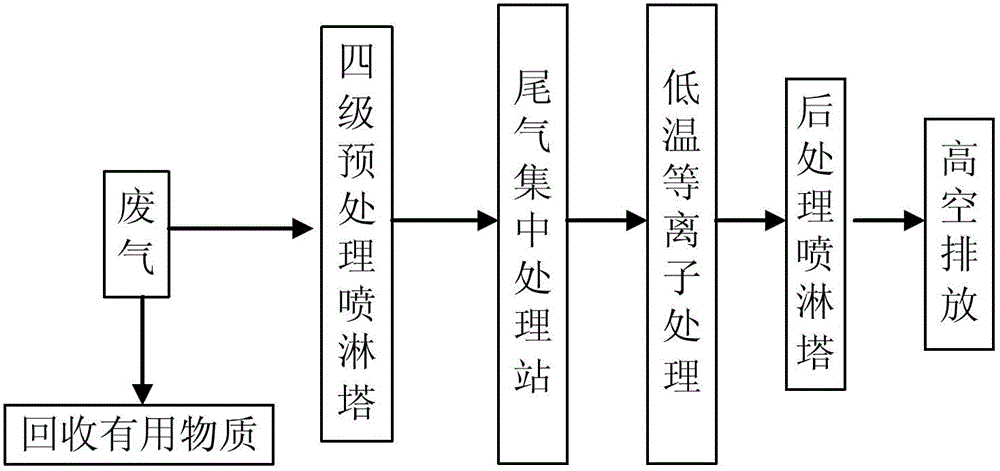

[0023] Such as figure 1 Shown, the processing method of waste gas in profenofos production of the present invention comprises the steps:

[0024] The recovery of trimethylamine and bromopropane in the waste gas is also included before the waste gas is passed into the pretreatment spray tower. The recovery process of the trimethylamine is: after the trimethylamine in the waste gas is condensed, it is absorbed by a mechanical W vacuum pump. The recovery process of the bromopropane is as follows: after condensing the trimethylamine in the exhaust gas, it is absorbed in a closed water-sealed tank.

[0025] (1) After recovering useful substances, the residual exhaust gas is passed into the pretreatment spray tower, and the pretreatment spray tower is four stages connected in series.

[0026] (2) Lead to the tail gas centralized treatment station for treatment. The tail gas centralized treatment station is a series of seven-stage waste gas absorption towers, and the absorbents co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com