Preparation method of supported phosphorus-vanadium catalyst and method for synthesizing methyl acrylate by use of supported phosphorus-vanadium catalyst

A technology of phosphorus vanadium catalyst and methyl acrylate, which is applied in the preparation of organic compounds, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of reduced catalytic activity and easy deactivation of catalysts, and achieve the goal of increased yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0027] Specific embodiment one: the preparation method of the supported phosphorus vanadium catalyst of the present embodiment is carried out according to the following steps:

[0028] 1. Dissolve 0.3-0.8g of lactic acid in 5ml of 70-80℃ water, then add 0.3-0.8g of NH 4 VO 3 , making a vanadyl lactate solution, and then adding 0.5-2 g of phosphoric acid to the vanadyl lactate solution to obtain an impregnation solution;

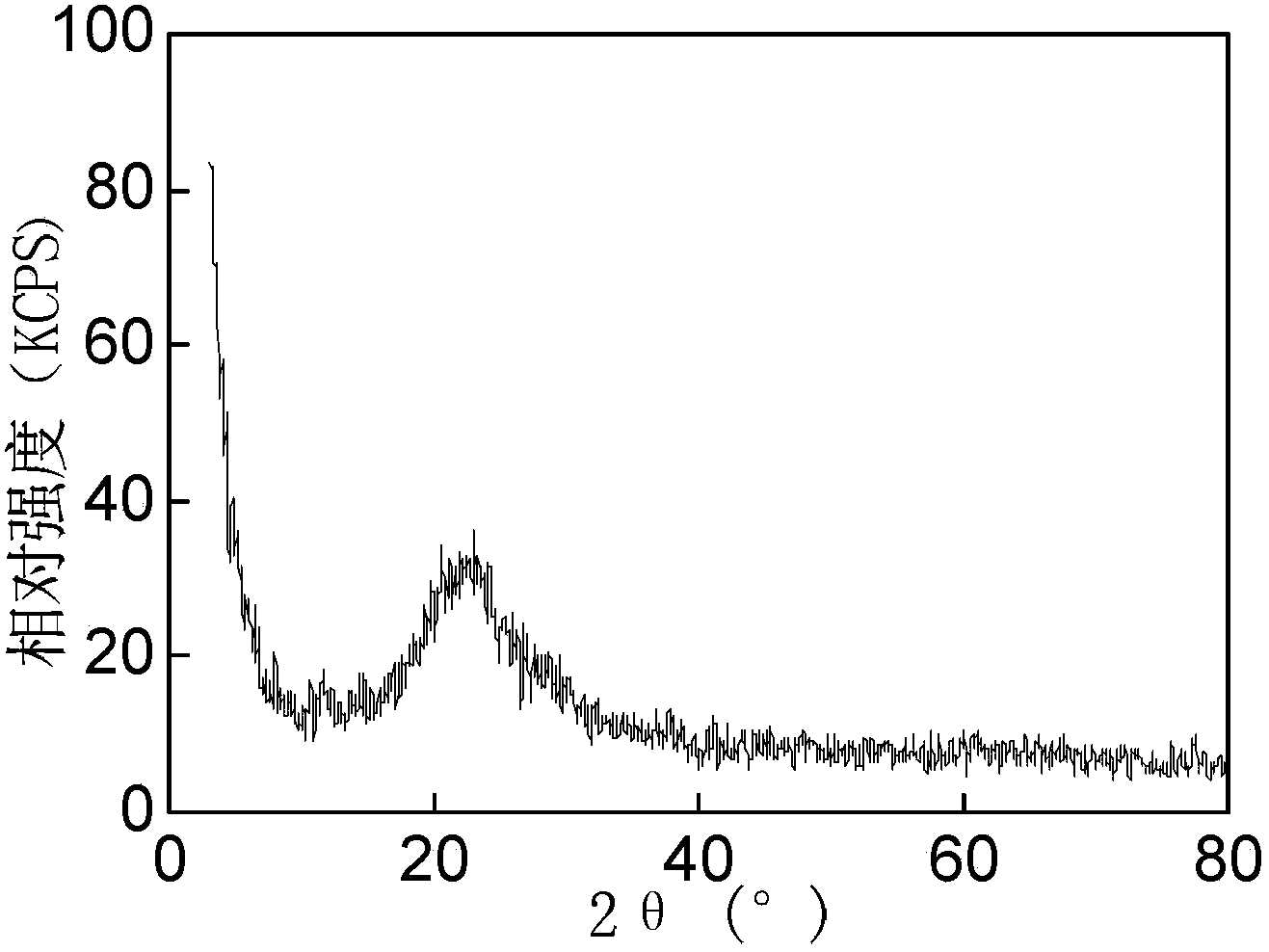

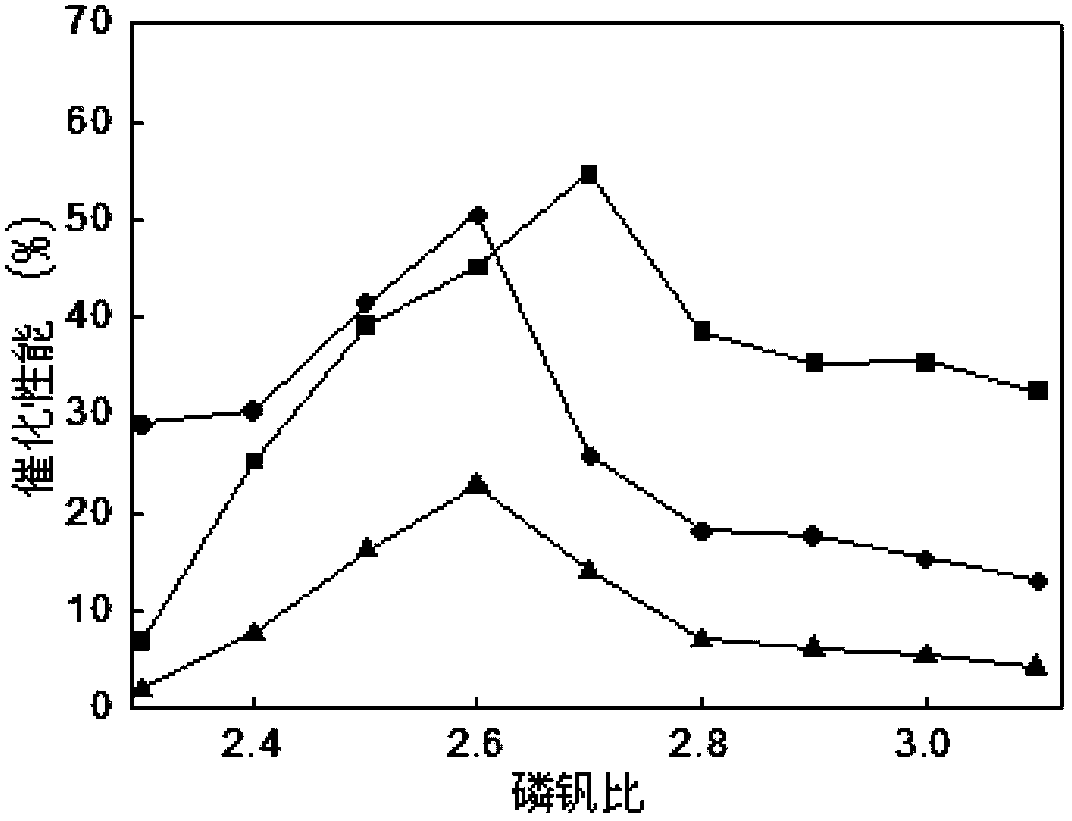

[0029] Second, the macroporous SiO 2 Add it into 20ml of water and stir to obtain a suspension, then stir the suspension and impregnation solution under microwave conditions at 60-100°C for 10-20 minutes, then evaporate to dryness in a water bath, and then dry at 80-120°C , and then burned at 200°C for 2-3 hours, at 300°C for 1-3 hours, and at 450°C for 2-4 hours, then pulverized and sieved to obtain a particle size of 20-40 mesh supported phosphorus vanadium catalyst, the atomic ratio of phosphorus atoms, vanadium atoms and silicon atoms in the supported ...

specific Embodiment approach 2

[0033] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the preparation method of supported phosphorus vanadium catalyst is carried out according to the following steps:

[0034] 1. Dissolve 0.5g of lactic acid in 5ml of 70°C water, then add 0.5g of NH 4 VO 3 , making a vanadyl lactate solution, and then adding 1.3 g of phosphoric acid to the vanadyl lactate solution to obtain an impregnation solution;

[0035] Second, the macroporous SiO 2Add it into 20ml of water and stir to obtain a suspension, then stir the suspension and impregnation solution under microwave conditions at 91°C for 20 minutes, then evaporate to dryness in a water bath, and then dry at 100°C to obtain a powder. Burning at 200°C for 2 hours, burning at 300°C for 1 hour, burning at 450°C for 3 hours, then crushing and sieving to obtain supported phosphorus vanadium with a particle size of 20-40 mesh In the catalyst, the atomic ratio of phosphorus atoms, va...

specific Embodiment approach 3

[0037] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 2, the suspension and the impregnating liquid are stirred under the microwave condition of 90°C. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com