Preparation method of POSS (Polyhedral Oligomeric Silsesquioxane) hybrid hydrogel capable of being degraded in acid and responding to temperature

A temperature-responsive, hydrogel technology, applied in the field of preparation of intelligent temperature-sensitive gels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

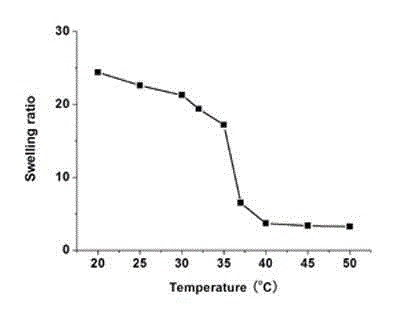

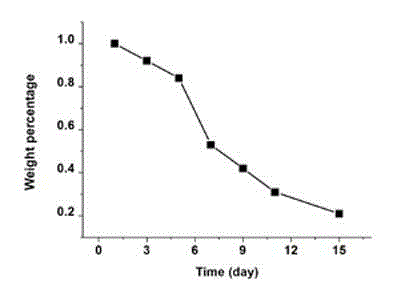

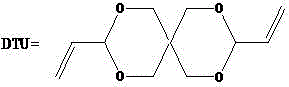

[0033] 4gNIPA, 1gNVP, 0.35gOvPOSS, 0.22g organic co-crosslinking agent DTU, 40mg AIBN were placed in a container, and stirred at room temperature for 60 minutes under nitrogen protection until uniform and transparent. Finally, add the catalyst, stir rapidly for 5 minutes and then seal it evenly. After ultrasonically oscillating the above pre-poly solution for 5 minutes, react at 60°C for 8 hours. Afterwards, take out and soak in deionized water repeatedly to change water to remove unreacted monomer and solvent to obtain the product.

[0034]

Embodiment 2

[0036] Put 4.5g NIPA, 0.9g NVP, 0.65g OvPOSS, 0.28g organic co-crosslinking agent DTU, 35.2mg AIBN in a container, and stir at room temperature for 60 minutes under nitrogen protection until it is uniform and transparent. Finally, add the catalyst, stir rapidly for 5 minutes and then seal it evenly. After ultrasonically oscillating the above pre-poly solution for 5 minutes, react at 60° C. for 12 hours. Afterwards, take out and soak in deionized water repeatedly to change water to remove unreacted monomer and solvent to obtain the product.

[0037]

Embodiment 3

[0039] Put 4.2g NIPA, 0.8gNVP, 0.45gOvPOSS, 0.32g organic co-crosslinking agent DTU, 50mg AIBN in a container, and stir at room temperature for 60 minutes under nitrogen protection until it is uniform and transparent. Finally, add the catalyst, stir rapidly for 5 minutes and then seal it evenly. After ultrasonically oscillating the above pre-poly solution for 5 minutes, react at 60° C. for 12 hours. Afterwards, take out and soak in deionized water repeatedly to change water to remove unreacted monomer and solvent to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com