Cashew nut shell oil-modified mixed-amine curing agent and preparation method

A cashew nut shell oil and curing agent technology, applied in the chemical field, can solve the problems of unsatisfactory mechanical properties, unstable color, low price-quality ratio, etc., and achieve the effects of cost and efficiency balance, stable color and good gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

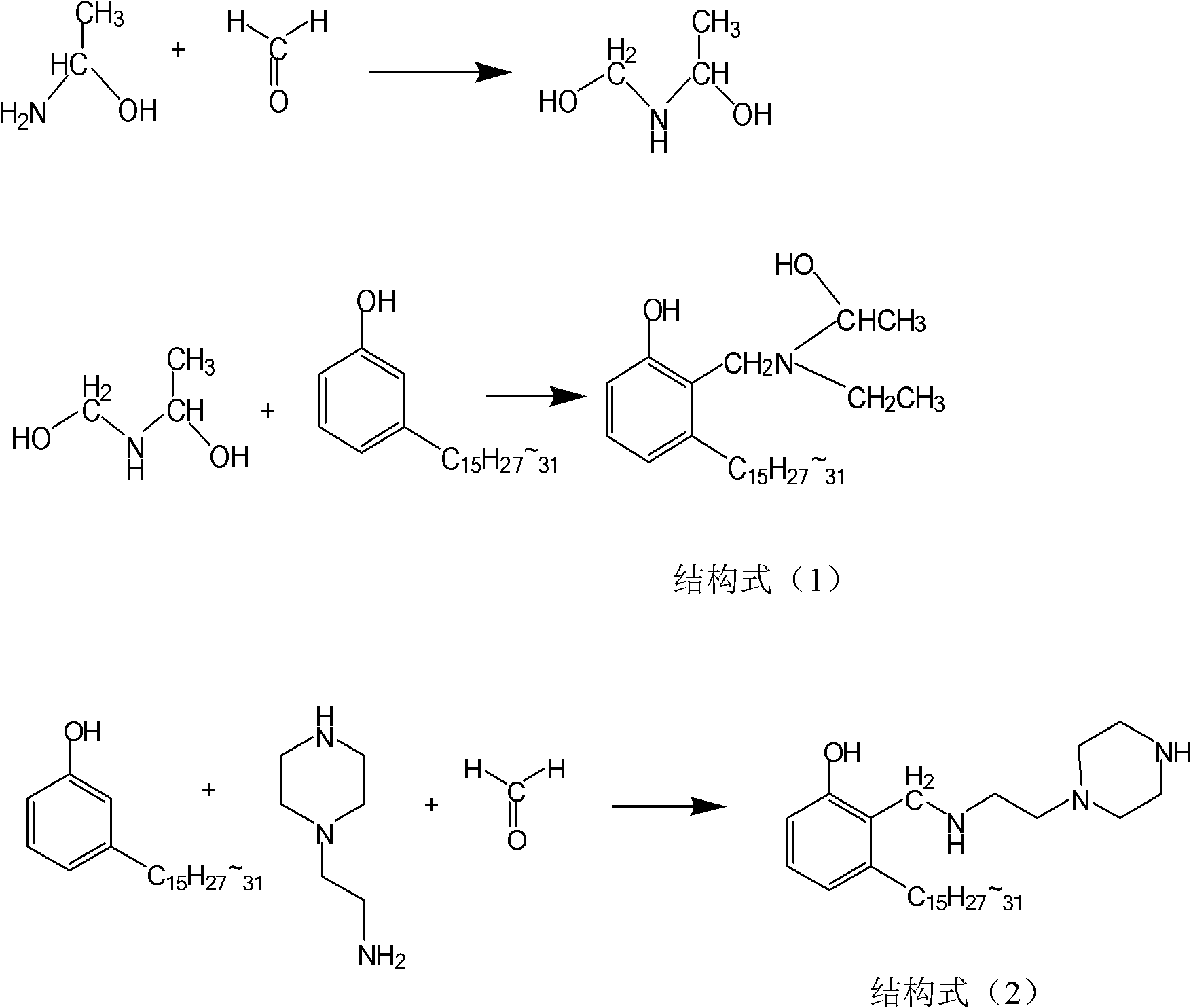

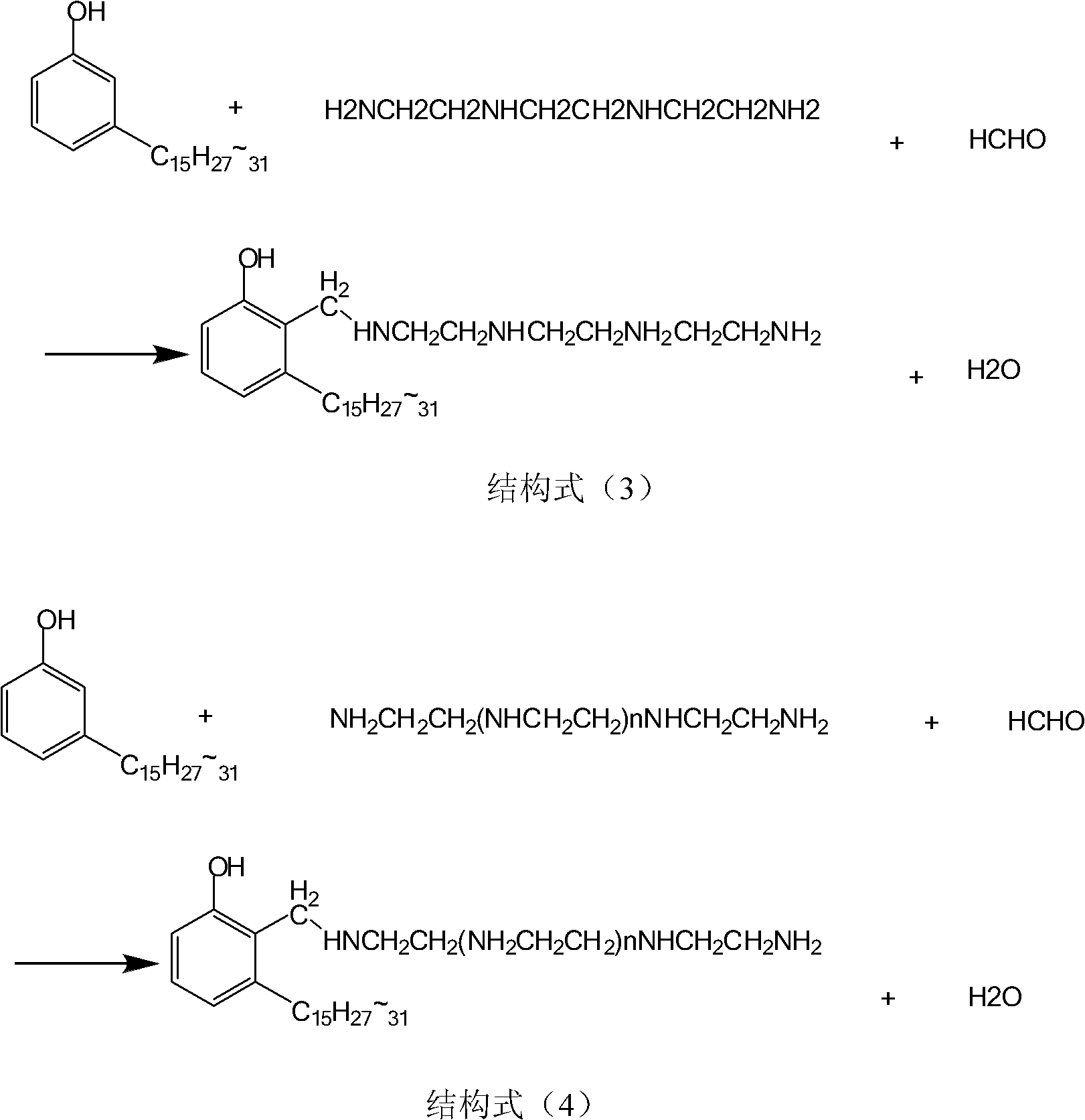

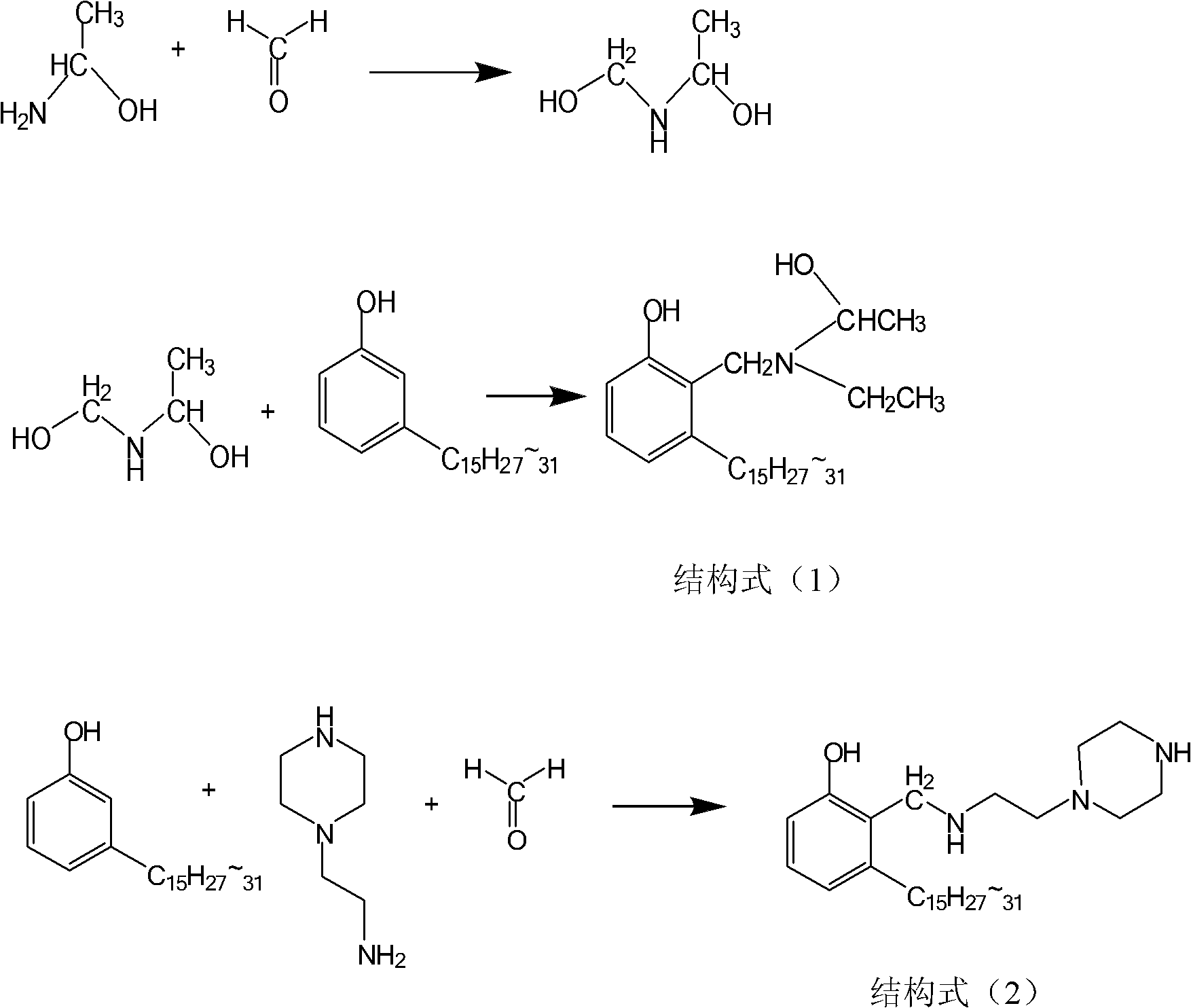

Method used

Image

Examples

Embodiment 1

[0021] Heat 100 grams of mixed amine to 90 degrees, add 30 grams of polyoxymethylene in batches to be completely dissolved, reflux for 30 minutes, then add 300 grams of cardanol, keep the temperature at 90 degrees and react for 3 hours, then dehydrate and discharge. The obtained product has a viscosity of 3200, an amine value of 270.48, a volatile content of 1.60%, a solid content of 97.40%, a gel time of 100:88, 37 minutes; dry film 55 microns, impact 50 cm, bending grade 1, adhesion grade 1, surface hardness HB ; Appearance is smooth, high gloss, no defects.

Embodiment 2

[0023] Heat 100 grams of mixed amine to 90 degrees, add 30 grams of polyoxymethylene in batches to be completely dissolved, reflux for 30 minutes, then add 300 grams of cardanol, keep the temperature at 90 degrees and react for 3 hours, then dehydrate and discharge. The obtained product has a viscosity of 3000, an amine value of 269.50, a volatile content of 1.20%, a solid content of 98.2%, a gel time of 100:88, 41 minutes; dry film 50 microns, impact 50 cm, bending grade 1, adhesion grade 1, surface hardness HB ; Appearance is smooth, high gloss, no defects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volatile matter | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com