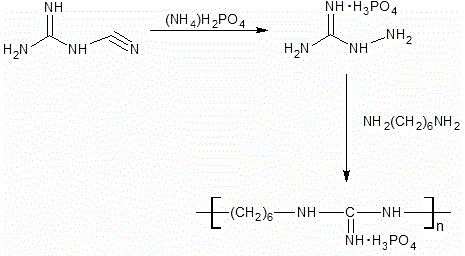

Polyhexamethylene guanidine phosphate and synthetic method thereof

A technology of polyhexamethylene guanidine phosphate and ammonium dihydrogen phosphate, which is applied in the fields of chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the limitation of inability to realize the reaction of guanidine and phosphoric acid, and disinfection and sterilization activity , poor solubility of the product and other problems, to achieve the effect of good mold killing effect, low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

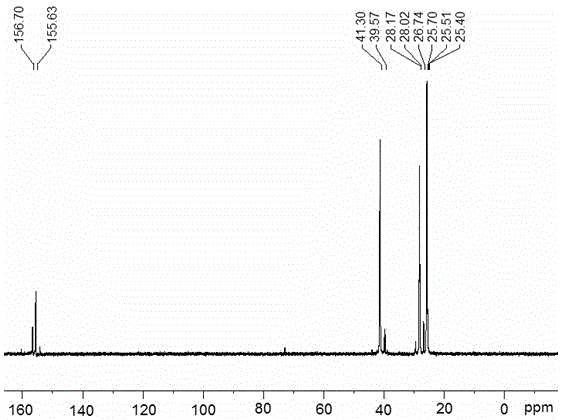

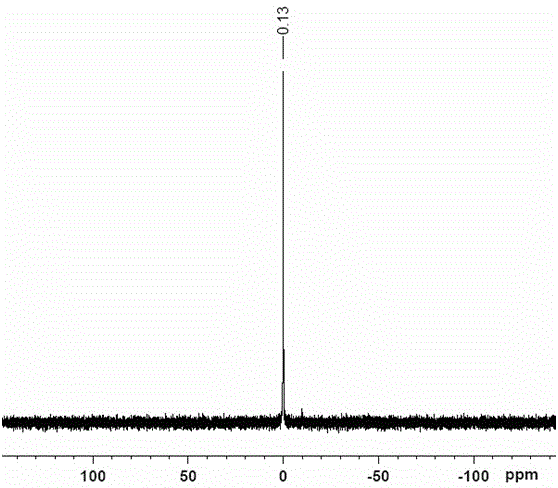

Image

Examples

Embodiment 1

[0027] Step 1, synthesis of aminoguanidine dihydrogen phosphate

[0028] Add 200 kg of dicyandiamide and 550 kg of ammonium dihydrogen phosphate into the rotary mixer, mix for 30 minutes, then start heating, stop heating when the temperature rises to 170~180°C, and keep it in this temperature range for 1 hour to obtain 660 kg Aminoguanidine Dihydrogen Phosphate.

[0029] Step 2, dihydrogen phosphate aminoguanidine salt and hexamethylenediamine copolymerization

[0030] Put 400 kg of aminoguanidine dihydrogen phosphate and 330 kg of 1,6-hexamethylenediamine into the reactor, add 0.8 kg of propylene glycol, and follow the predetermined program at 100°C (1h for heat preservation)-150°C (2h for heat preservation)-200°C ( Keep warm for 2 hours) -250°C (keep warm for 0.5 hours) and gradually increase the temperature. After the reaction, a polyhexamethyleneguanidine phosphate polymer melt is obtained.

[0031] Cooling, obtain 670 kilograms of polyhexamethylene guanidine phosphates,...

Embodiment 2

[0033] Step 1, synthesis of aminoguanidine dihydrogen phosphate

[0034] Add 300 kg of dicyandiamide and 820 kg of ammonium dihydrogen phosphate into the rotary mixer, mix for 30 minutes, then start heating, stop heating when the temperature rises to 170~180°C, and keep it in this temperature range for 2 hours to obtain 990 kg Aminoguanidine Dihydrogen Phosphate.

[0035] Step 2, dihydrogen phosphate aminoguanidine salt and hexamethylenediamine copolymerization

[0036] Put 800 kg of aminoguanidine dihydrogen phosphate and 660 kg of 1,6-hexamethylenediamine into the reactor, add 0.8 kg of ethylene glycol, and follow the predetermined procedure at 100°C (1.5h for heat preservation)-150°C (1.5h for heat preservation) -200°C (1.5h of heat preservation) -250°C (1h of heat preservation) gradually increase the temperature, and after the reaction is completed, a polyhexamethylene guanidine phosphate polymer melt is obtained.

[0037] Cooling, obtain 1340 kilograms of polyhexamethyl...

Embodiment 3

[0039] Step 1, synthesis of aminoguanidine dihydrogen phosphate

[0040] Add 320 kg of dicyandiamide and 880 kg of ammonium dihydrogen phosphate into the rotary mixer, mix for 30 minutes, then start heating, stop heating when the temperature rises to 170~180°C, and keep it in this temperature range for 1.5 hours to obtain about 1000 Kilograms of aminoguanidine dihydrogen phosphate.

[0041] Step 2, dihydrogen phosphate aminoguanidine salt and hexamethylenediamine copolymerization

[0042] Put 500 kg of aminoguanidine dihydrogen phosphate and 400 kg of 1,6-hexamethylenediamine into the reactor, add 0.8 kg of PEG200, and follow the predetermined procedure at 100°C (2h for heat preservation)-150°C (2.5h for heat preservation)-200°C (2.5 hours of heat preservation) -250° C. (1.5 hours of heat preservation) gradually increase the temperature, and obtain a polyhexamethylene guanidine phosphate polymer melt after the reaction.

[0043] Cooling, obtain 650 kilograms of polyhexamethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com