Vitreous tile adhesive

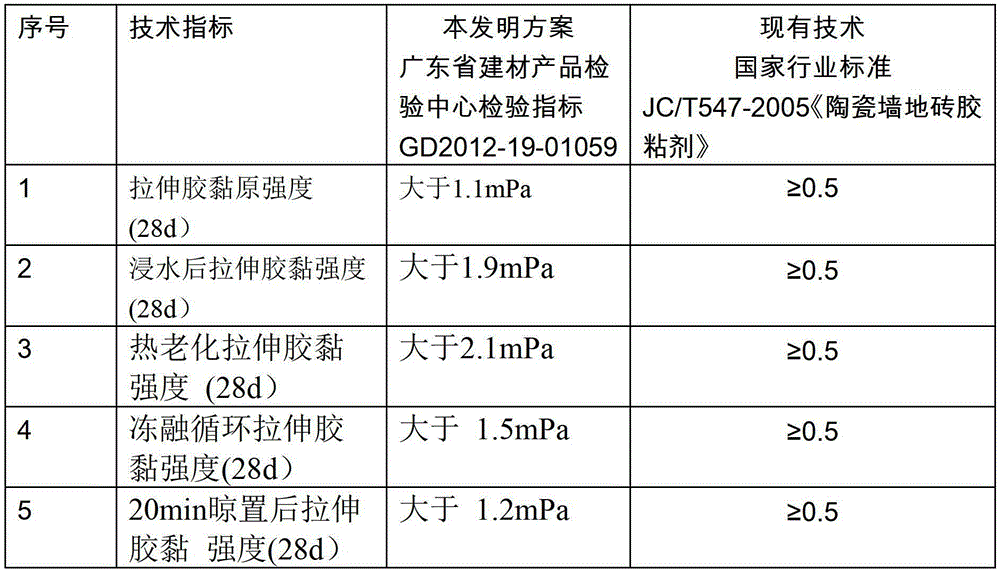

A tile adhesive and vitrification technology, applied in the direction of adhesives, adhesive types, inorganic adhesives, etc., can solve problems affecting building and personal safety, low water absorption, tile falling off, etc., to improve adaptability to the external environment The ability to improve the bonding performance and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A vitrified tile adhesive, comprising liquid material component A and powder material component B, the liquid material component A and powder material component B are weighed and placed at a ratio of 1:3 to 4 according to the weight fraction ratio, and the liquid material component A and the powder material component B are weighed and placed. Pour material component A into powder material component B and stir evenly. Stir evenly without agglomeration. Leave the prepared slurry for 5 to 10 minutes, and then use a mixer to mix well before construction;

[0027] The liquid material component A includes the following components, and the weight fraction ratios of the components are expressed as follows: 70-80 parts of a styrene-acrylate emulsion with a solid content of 40%-60%; 3-5 parts of a water-retaining agent; 0-1 part of mildew and anti-algae agent; 1-2 parts of preservative; 0-2 parts of defoamer; 10-20 parts of purified water,

[0028] The powder component B includes...

Embodiment 2

[0030] The liquid material component A and the powder material component B are weighed and placed at a ratio of 1:3.5 according to the weight fraction.

[0031] The liquid material component A includes the following components, and the weight fraction ratios of the components are expressed as follows: 75-80 parts of a styrene-acrylate emulsion with a solid content of 40%-60%; 3-5 parts of a water-retaining agent; 0-1 part of mildew and anti-algae agent; 1-2 parts of preservative; 0-2 parts of defoamer; 10-15 parts of purified water,

[0032] The powder component B includes the following components, and the proportions of the components are expressed as follows: 50 parts of cement; 50 parts of mineral fillers.

[0033] The cement material is ordinary Portland cement (PO42.5R).

[0034] The mineral filler is any one of wollastonite, microsilica powder, kaolin, and fine aggregates with a silicon dioxide content >99%.

[0035] The water-retaining agent is a kind of methyl cellul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com