Dark-l fermentation integrated biological hydrogen production device

A technology of biological hydrogen production and photofermentation, which is applied in the direction of gas production bioreactors, microorganisms, and methods based on microorganisms, can solve the problems of low coupling hydrogen production efficiency, achieve unbalanced growth and metabolic rates, avoid shading effects, Effect of improving hydrogen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

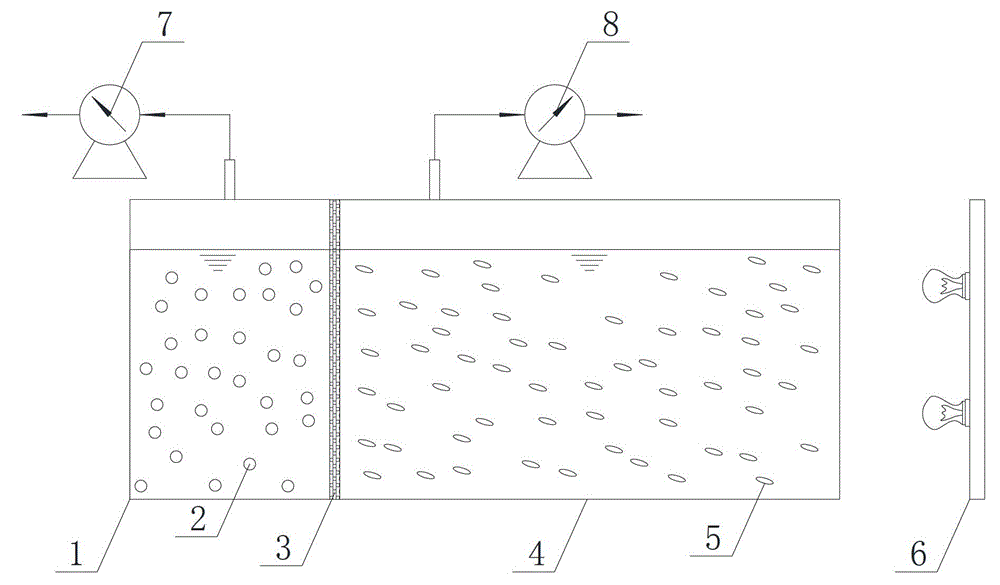

[0016] Specific implementation mode one: below in conjunction with attached figure 1 To further explain the specific embodiment: In this embodiment, the dark-light fermentation integrated biohydrogen production device includes a dark fermentation reaction zone 1, a filter membrane 3, a light fermentation reaction zone 4, a lighting system 6, a dark fermentation gas flow meter 7 and a light fermentation reaction zone. Gas flow meter 8, the biological hydrogen production reaction vessel is divided into a dark fermentation reaction zone 1 and a light fermentation reaction zone 4 through a filter membrane 3, a dark fermentation gas flow meter 7 is set on the dark fermentation reaction zone 1, and a dark fermentation gas flow meter 7 is set on the light fermentation reaction zone 4 There is a light fermentation gas flow meter 8, and an illumination system 6 is installed on one side of the light fermentation reaction zone 4, wherein the working volume of the dark fermentation reactio...

specific Embodiment approach 2

[0021] Specific embodiment 2: The dark fermentation bacteria added in the dark fermentation reaction zone 1 of this embodiment are Clostridium butyricum DSM10702, Enterobacter aerogenes DSM30053 or Ethanologenbacterium hit B49.

[0022] The bacteria described in this embodiment are all purchased.

specific Embodiment approach 3

[0023] Specific embodiment three: The photofermentation bacteria that can be added to the photofermentation reaction zone 4 of this embodiment are Rhodospirillum rubrum ATCC25903, Rhodopseudomonas RLD-119 or Rhodopseudomonas ( Rhodopseudomonas faecalis) RLD-53.

[0024] The bacteria described in this embodiment are all purchased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com