Trace water detecting device by taking water inside component of optical fiber gas sensor as reference

A technology of gas sensor and optical fiber collimator, which is applied in the direction of color/spectral characteristic measurement, etc., can solve problems that have not been considered, and achieve the effect of convenient waveform adjustment and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

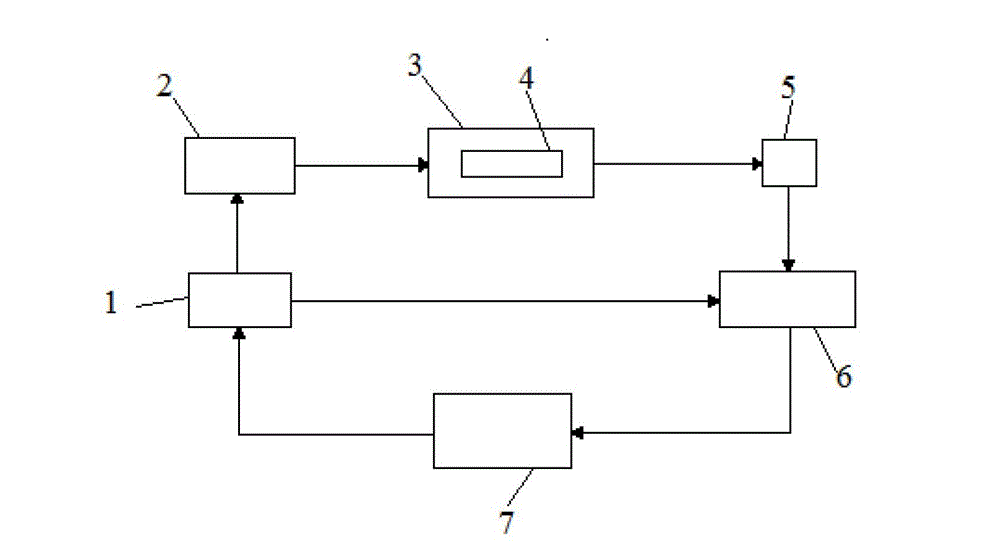

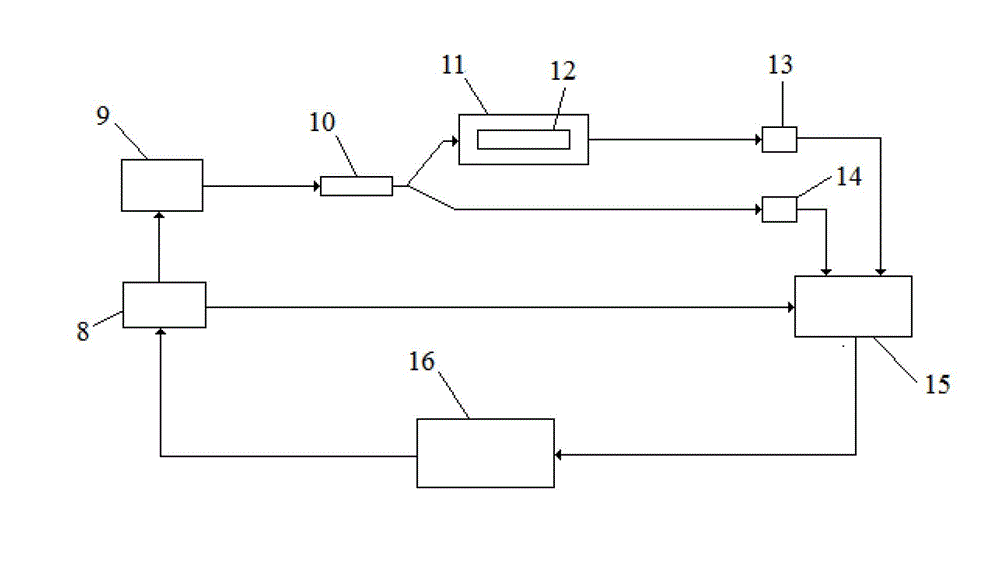

[0034] Embodiment 1 of the device of the present invention is as follows Figure 1-2 As shown, it includes a calibration system, a DFB laser 2, an air chamber 3, a fiber collimator 4, a PIN photodetector 5, a differential amplifier circuit 6, a filter circuit 7 and a single-chip microcomputer 1, and is characterized in that the DFB laser 2 is located in front of the air chamber 3 , the fiber collimator 4 is located in the gas chamber 3, the PIN photodetector 5 is located behind the fiber collimator 4, the fiber collimator 4 is coupled to the PIN photodetector 5 through a single-mode fiber connection, and the PIN photodetector 5 outputs The terminal is connected to an input terminal of the differential amplifier circuit 6, the output terminal of the differential amplifier circuit 6 is connected to the filter circuit 7, and the output terminal of the filter circuit 7 is connected to the A / D acquisition terminal of the single-chip microcomputer 1; the single-chip computer 1 and th...

Embodiment 2

[0037] A method for calibrating the water content inside the device using the calibration system of the above-mentioned detection device, the steps are as follows:

[0038] Connect the calibration system; turn on the power of the oscilloscope, turn on the power of the calibration system; debug the optical path and circuit to make it work normally;

[0039] Connect the photoelectric conversion signal of the second PIN photodetector and the trapezoidal wave signal generated by the single-chip microcomputer to the two input ends of the differential amplifier circuit; adjust the magnification of the photoelectric conversion signal of the second PIN photodetector, and connect the oscilloscope to the second PIN photoelectric conversion signal. The output terminal of the PIN photodetector observes its waveform until the amplitude and slope of the photoelectric conversion signal of the second PIN photodetector are consistent with the trapezoidal wave signal generated by the single-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com