Methods for manufacturing electrode and energy storage device, and energy storage device

A manufacturing method and energy storage device technology, which is applied to the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of insufficient water removal, large energy consumption, and long baking time, so as to save energy and improve Good product capacity and anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

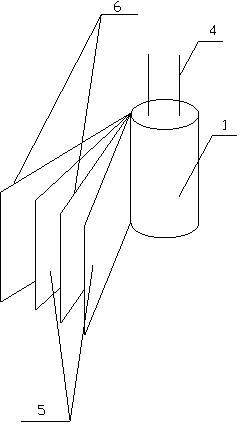

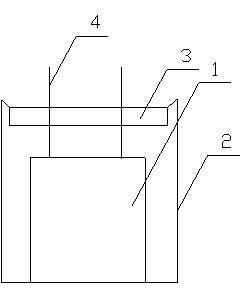

Image

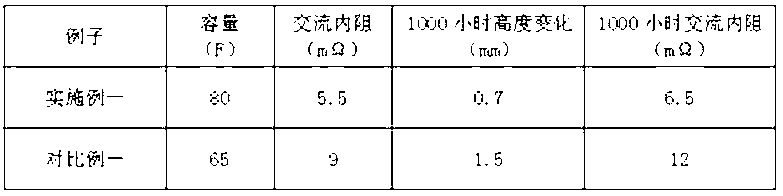

Examples

Embodiment 1

[0041] The manufacturing method of energy storage device of the present invention:

[0042] Step 1, with a specific surface area of 1500m 2 Activated carbon above / g is an active substance; Conductive carbon black or conductive graphite or a mixture of the two is used as a conductive agent, and PTFE dispersed resin is used as a binder, and is dry mixed in a mixer. The weight ratio of activated carbon to conductive agent and PTFE dispersed resin is 8:1:1;

[0043] Step 2, banburying the mixture for 1 minute in a pressurized internal mixer;

[0044] Step 3, passing the material after banbury mixing through a heating type open mill, and open refining for 3 times;

[0045] Step 4: Feed the refined material through a conveyor belt, and heat and roll it three times in a four-roller press to form a self-supporting membrane;

[0046] Step 5, the aluminum foil current collector is coated with conductive glue, and before the conductive glue is dried, it is attached to the self-supp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com