Method for producing planar thermopile for thermometers

A manufacturing method and thermopile technology, applied in the manufacture/processing of thermoelectric devices, etc., can solve problems such as poor placement uniformity of thermocouples, difficulty in ensuring temperature measurement sensitivity, and difficulty in processing planar thermopile, so as to reduce relative error and high practicality value, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

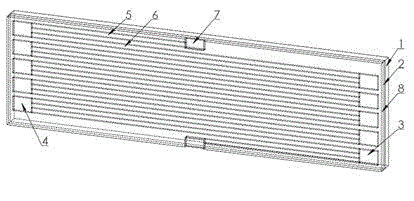

[0027] The specific steps of a method for manufacturing a planar thermopile for a calorimeter are:

[0028] The first step is to make a metal photolithography mask

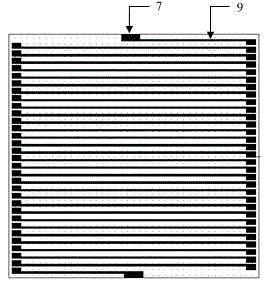

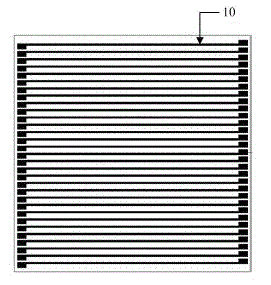

[0029] Make the mask plate required for the photolithography of nickel metal 9 and platinum metal 10, expose the patterns of nickel metal 9 and platinum metal 10 on the chromium plate at a working temperature of 1600K, and expose the patterns of nickel metal 9 and platinum metal 10 one by one Elemental exposure, making a mask pattern with a magnification of 1:5.

[0030] The second step is to process the mask for dry etching and pad lithography

[0031] Make the mask plate required for dry etching and pad 7 thickening, and use electron beam exposure technology to expose the pattern elements of pad 7 one by one at a working temperature of 1600K on the chromium plate for dry etching and pad 7, Make a mask pattern with 1:5 magnification.

[0032] The third step is to grow the insulating layer

[0033] On the subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com