Organic film forming device and organic film forming method

A technology for organic film and film-forming objects, which is applied in lighting devices, optomechanical equipment, and components used in photomechanical processing. It can solve the problems of re-evaporation of organic materials and difficulty in film formation, and achieve the effect of preventing re-evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

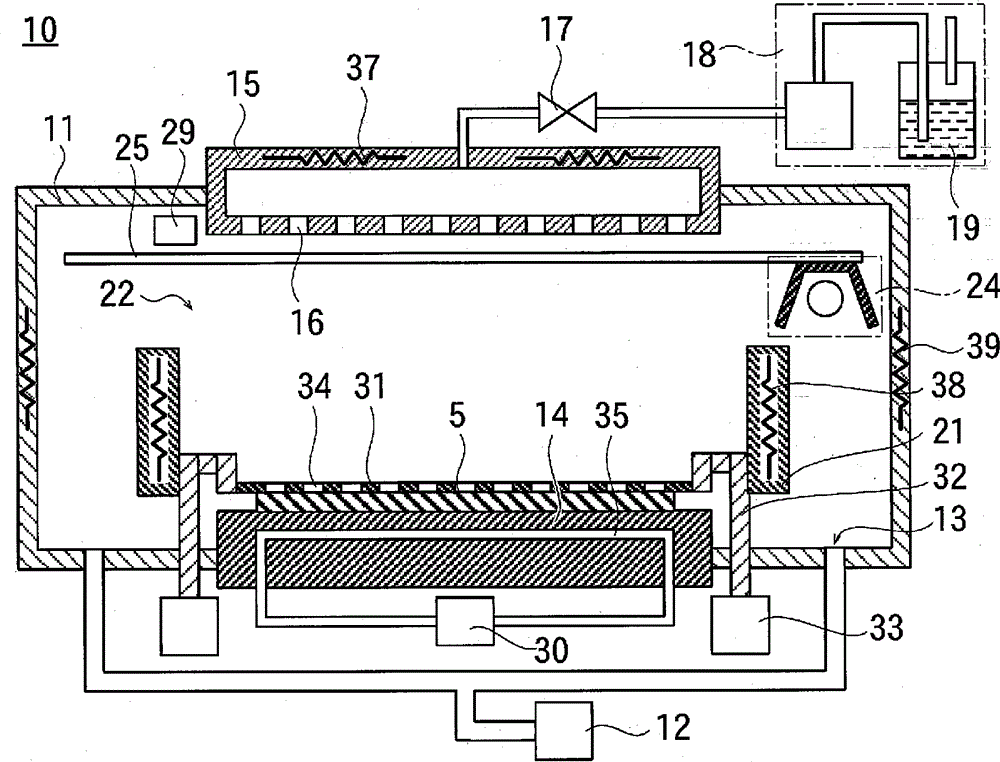

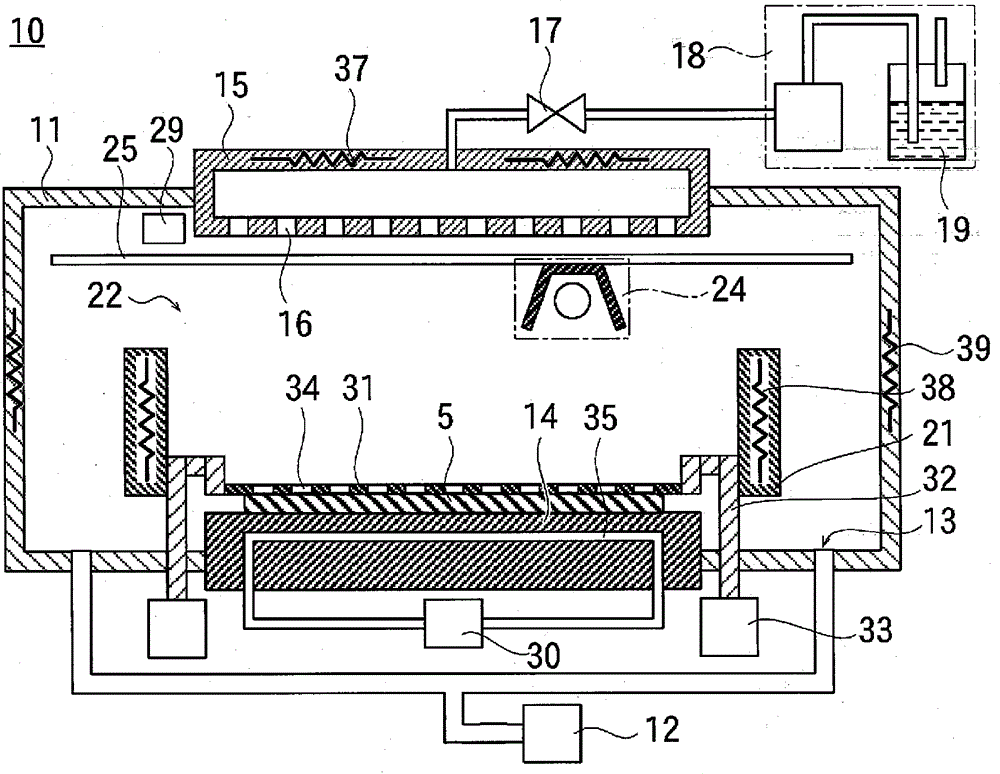

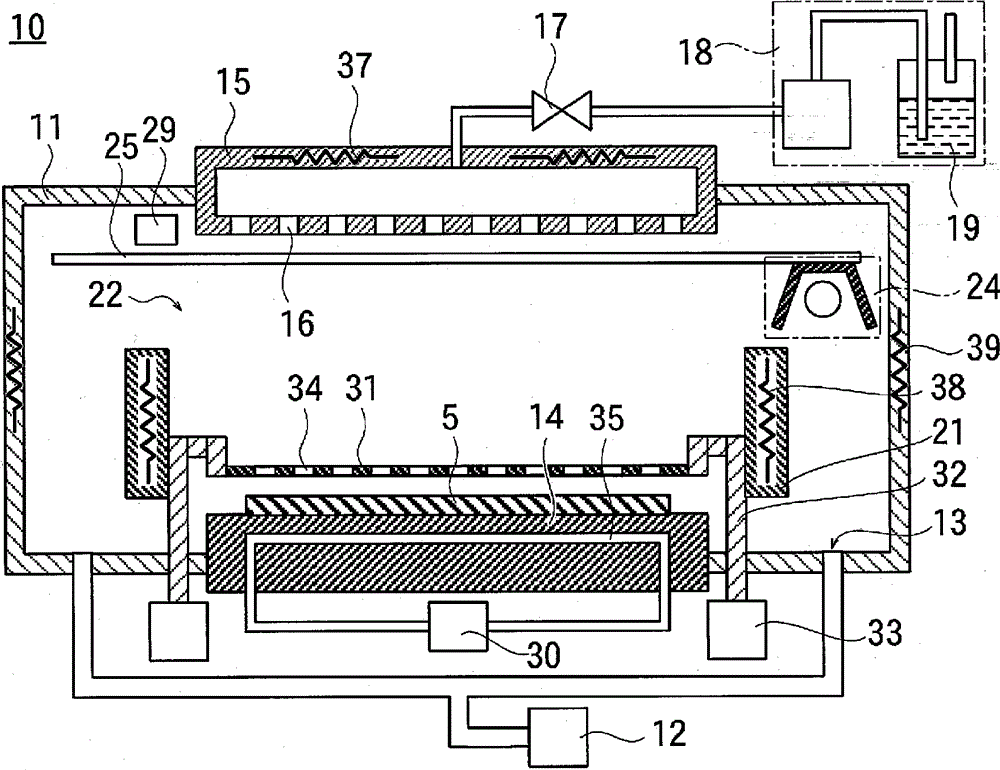

[0025] refer to figure 1 , reference numeral 10 is the organic film forming apparatus of the present invention, and reference numeral 5 denotes a film-forming object on which an organic film is formed on the surface by the organic film forming apparatus 10 .

[0026] This organic film forming apparatus 10 has: a vacuum chamber 11 to which a vacuum pump 12 is connected, a substrate stage 14 on which a film-forming object 5 is arranged, and a photoreactive material in either or both of a gaseous state and a droplet state. The carrier gas is supplied to the raw material supply device 18 of the shower plate 15 .

[0027] The inside of the shower plate 15 is hollow, and the photoreactive material supplied together with the carrier gas from the material supply device 18 is introduced into the hollow portion. The shower plate 15 is provided with a plurality of ejection ports 16 connected to the hollow portion on one surface thereof, and the photoreactive material is ejected from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com