Plasma processing apparatus

A processing device and plasma technology, applied in the directions of plasma, coating, gaseous chemical plating, etc., can solve the problems of inability to stably supply plasma, insufficient cooling of antenna conductors, insufficient cooling of dielectric tubes, etc., and achieve easy maintenance and repair. , The shape is simple, the effect of preventing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

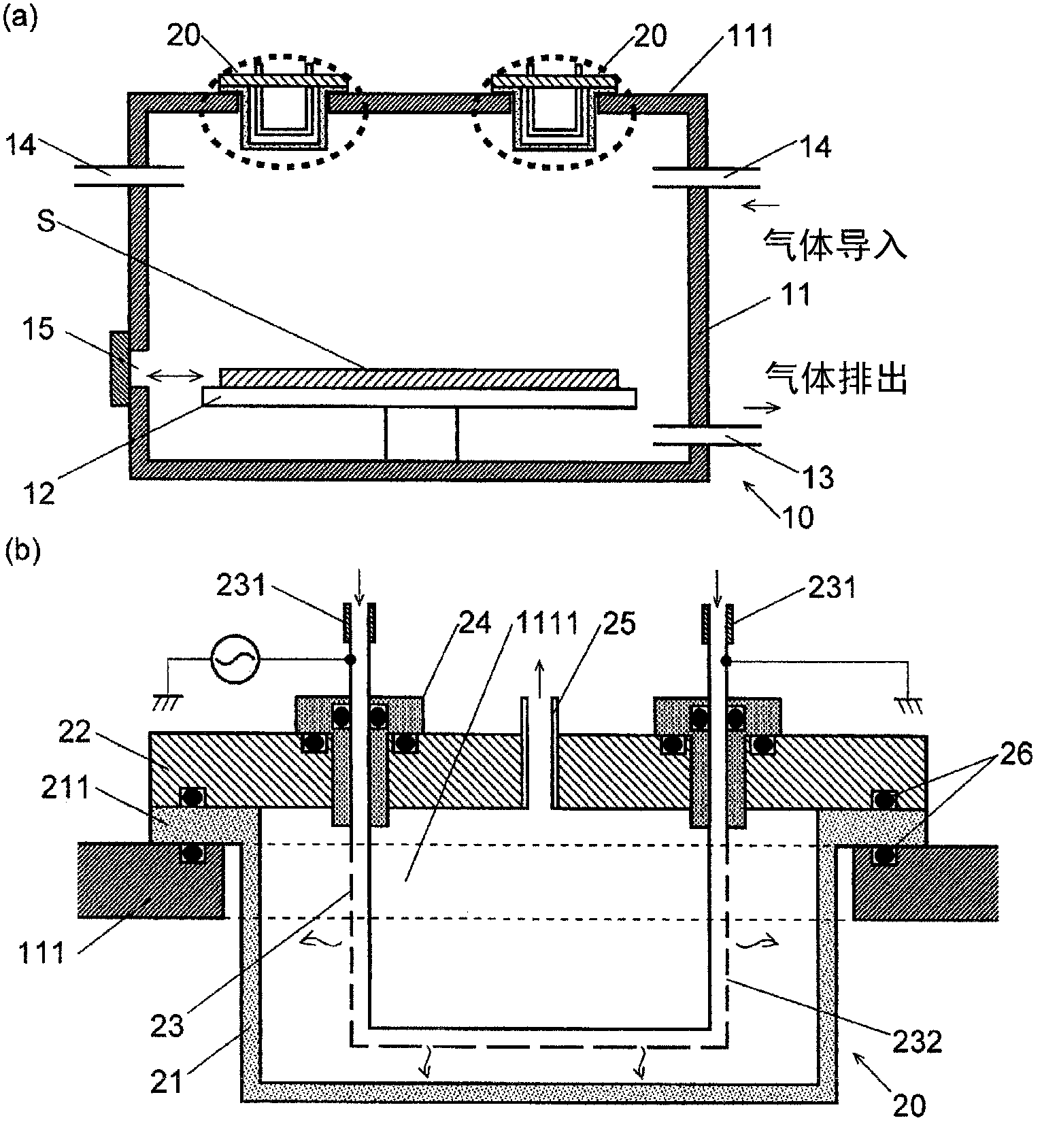

[0040] First, the plasma processing apparatus 10 of the first embodiment will be described. Such as figure 1As shown in (a), the plasma processing apparatus 10 is provided with a vacuum vessel 11, a substrate holding portion 12 arranged in the vacuum vessel 11, a first gas discharge port 13 and a first gas introduction port 14 provided on the side wall of the vacuum vessel 11. , and a plurality of antenna units 20 are provided on the upper wall 111 of the vacuum container 11 . The first gas outlet 13 is connected to a vacuum pump, and the air, water vapor, etc. in the vacuum container 11 are discharged from the first gas outlet 13 by means of the vacuum pump, thereby making the inside of the vacuum container 11 into a high vacuum state. The first gas introduction port 14 is used to introduce a plasma generation gas such as hydrogen gas or a source gas into the vacuum vessel 11 . The substrate S held by the substrate holding unit 12 is carried into or out of the vacuum contai...

Embodiment 2

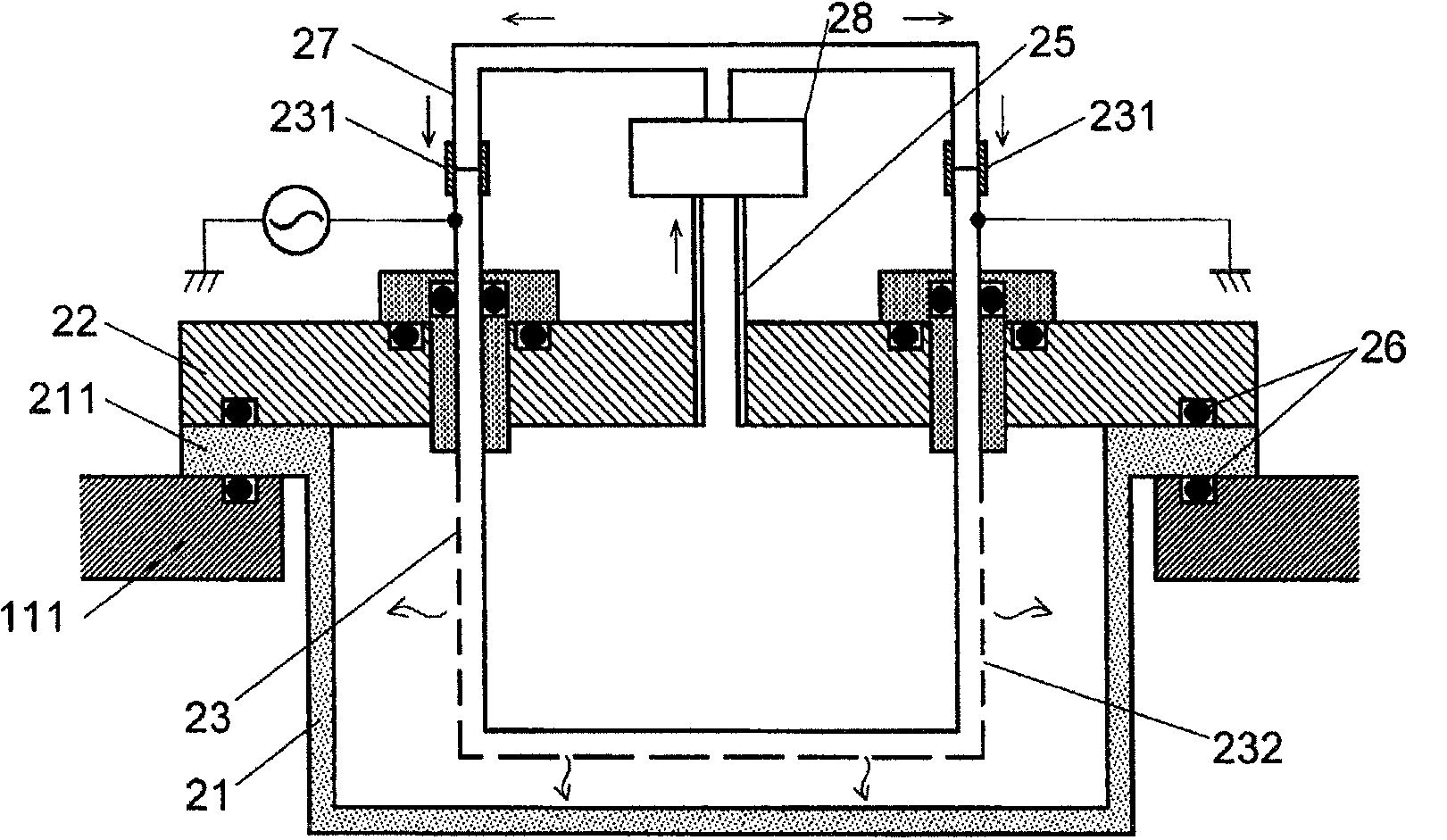

[0051] In the plasma processing apparatus 10 of the first embodiment, as image 3 As shown, the second gas outlet 25 is connected to the second gas inlet 231 by a connecting pipe 27, and a pump and a heat exchanger 28 may be provided between the two. Here, the second gas introduction port 231 connected to the high-frequency power source side and the connection pipe 27 are electrically insulated by interposing an insulator therebetween or forming the connection pipe 27 as an insulator. With such a configuration, the inert gas discharged from the second gas outlet 25 is cooled by the heat exchanger 28 and can be introduced again into the second gas inlet 231 , so that the inert gas can be circulated and reused. Furthermore, when economical efficiency is prioritized, the air can be circulated as cooling gas.

Embodiment 3

[0053] In the plasma processing apparatus 10 of the first embodiment, the dielectric housing 21 is attached so as to cover the opening 1111 of the vacuum vessel 11 from below, and the cover 22 is attached so as to cover the opening 1111 from above ( Figure 4 (a)). In this case, the flange portion 211 of the dielectric frame 21 is fixed to the lower surface of the upper wall 111 , and the cover 22 is fixed to the upper surface of the upper wall 111 . Alternatively, the dielectric frame 21 may be installed on the lower surface of the upper wall 111 having no opening ( Figure 4 (b)). In this case, the high-frequency antenna 23 is fixed to the upper wall 111 . Also, no cover is required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com