Laser navigation system of unmanned combine-harvester

A combine harvester and laser navigation technology, applied in the field of laser navigation systems, can solve the problems of low automation and intelligence of agricultural machinery equipment, inability to automatically find wheat boundaries efficiently, high cost of unmanned combine harvesters, etc., to achieve online Real-time control, easy to master technology, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

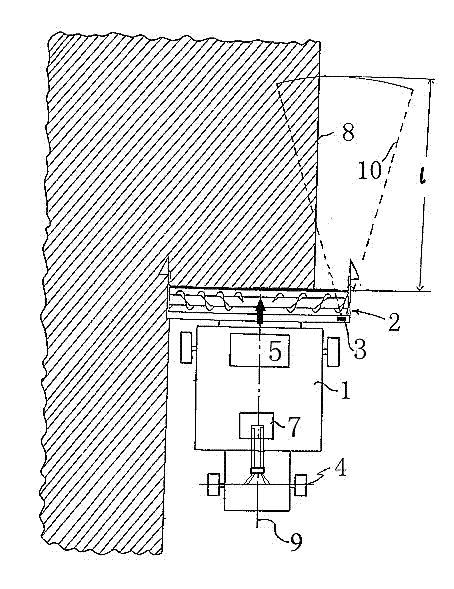

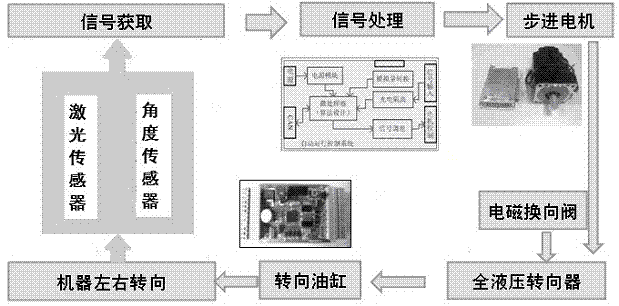

[0036] see Figure 1 to Figure 5 , the laser navigation system of the unmanned combine harvester, including a laser sensor and an angle sensor, a microprocessor, a GPRS module and an automatic steering device, is characterized in that: the laser sensor is installed on the right side of the cutter of the combine harvester on the bracket, and be connected with the microprocessor through the bus; the angle sensor is installed on the bracket supporting the laser sensor to measure the angle of rotation, and it is connected with the microprocessor through the bus; the GPRS module is directly connected with the microprocessor through The automatic steering device includes an electromagnetic reversing valve, a full hydraulic steering gear, a steering cylinder and wheels, and the electromagnetic reversing valve and the full hydraulic steering gear are connected to a microprocessor through a bus. One end is connected to the steering oil cylinder; the microprocessor is installed in the c...

Embodiment 2

[0038] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

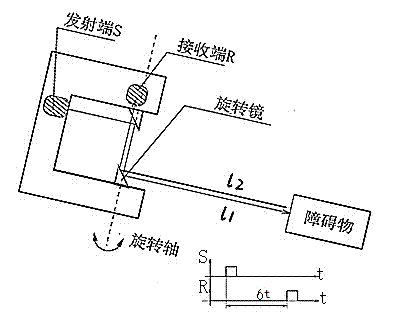

[0039]The laser sensor is a laser ranging sensor DLS-B(H) from DIMETIX AG, which can determine the boundaries of harvested wheat and unharvested wheat by scanning the wheat field.

[0040] The microprocessor is the ARM9 series microprocessor S3C2440A of Samsung, which receives the signals sent by each module, performs calculation and analysis, and sends control instructions to each module.

[0041] Described GPRS module is a commonly used GPRS module that carries on the described ARM9 series microprocessor S3C2440A, is directly connected to microprocessor interface by bus line, realizes wireless data transmission by this module and remote control center, is convenient to combine harvester Realize remote control.

[0042] The angle sensor adopts the REP absolute value encoder JSP3806 rotary encoder, which is used to measure the boundary information of the transmitted crops....

Embodiment 3

[0044] The structure and working principle of the laser navigation system of this unmanned combine harvester are as follows:

[0045] like figure 1 Shown, the wheat harvester 1 that has microprocessor 5 and automatic steering device 7 harvests wheat between wheat fields. The cutter 2 is installed on the wheat harvester 1, and the laser sensor 3 is installed on the right end of the cutter 2 through a bracket, so that it is as close as possible to the boundary of the wheat when harvesting, so that the central axis of the scanning light of the laser sensor 3 is on the boundary with the wheat. The direction of 8 is consistent, just can make microprocessor 5 have great advantage in the process of controlling the automatic steering of wheel, and can simplify geometric relationship. The rear wheels 4 of the combine harvester are used for driving.

[0046] The unmanned combine harvester 1 based on laser navigation technology is a common combine harvester, which travels in a wheat fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com