Biodegradable oil-water separation net film with super-hydrophobic and super-oleophylic properties and preparation method thereof.

A technology for oil-water separation omentum and phase separation, applied in separation methods, liquid separation, semi-permeable membrane separation, etc., can solve the problems of complex experimental operation and large influence on membrane properties, and achieve simple experimental operation, simple preparation method, speed-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1, the preparation of a degradable oil-water separation omentum with superhydrophobic and superoleophilic properties with a plant fiber addition of 3.75%

[0037] (1) the PLA that the weight average molecular weight molecular weight is 69000 is dissolved in 1,4-oxane solvent, is mixed with the solution that concentration is 0.1g / mL, adds the kapok staple fiber (average length is less than 3mm) that shears, The mass ratio of the kapok fiber to the PLA is 3.75%, and the mixture is stirred to form a uniform mixture, and then the mixture is evenly spread on the glass substrate.

[0038] (2) Submerge the glass substrate coated with the solution in absolute ethanol for 30 minutes to perform phase separation to form a thin film.

[0039] (3) Take it out and put it into an oven to dry at 40° C. to obtain the superhydrophobic and superoleophilic biodegradable oil-water separation omentum.

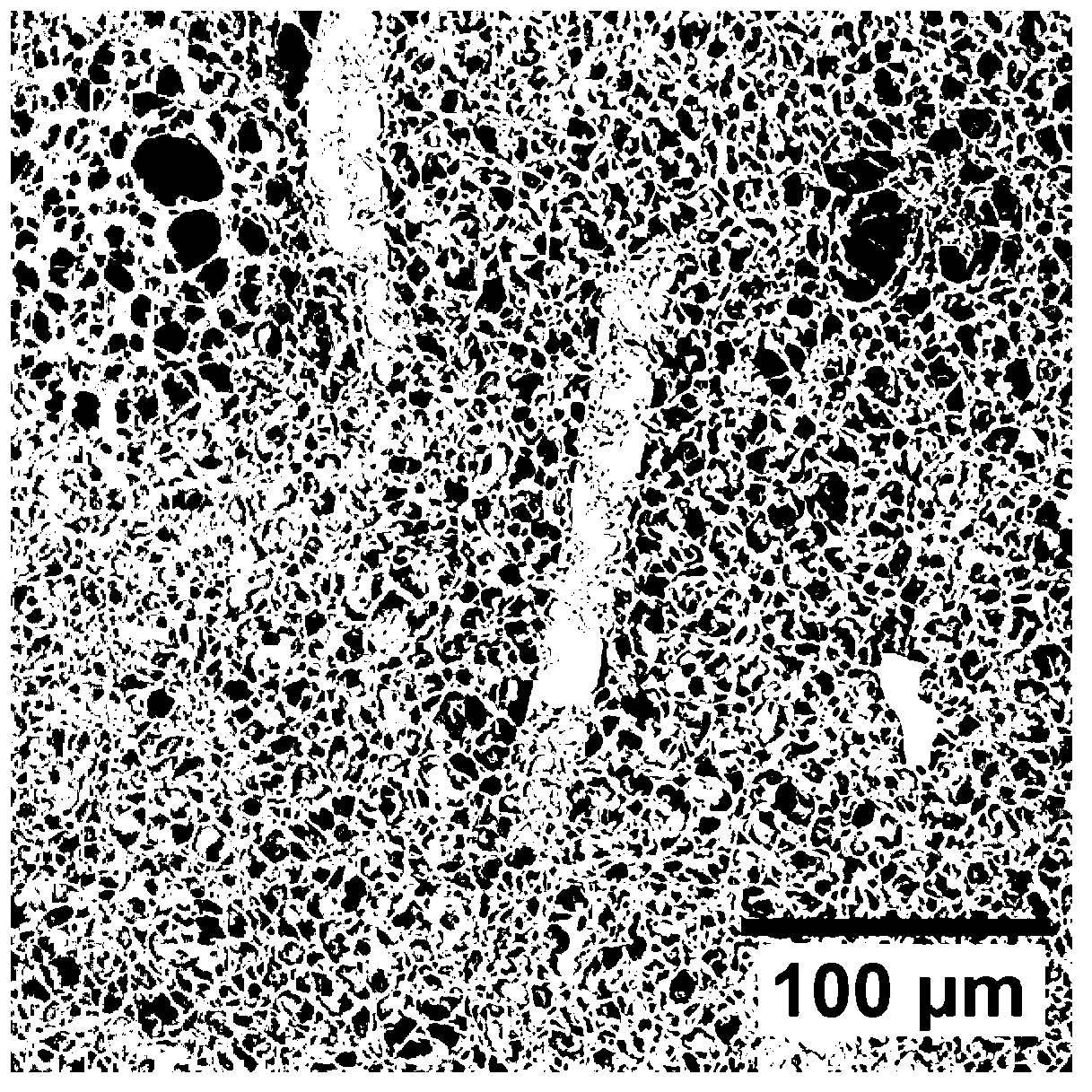

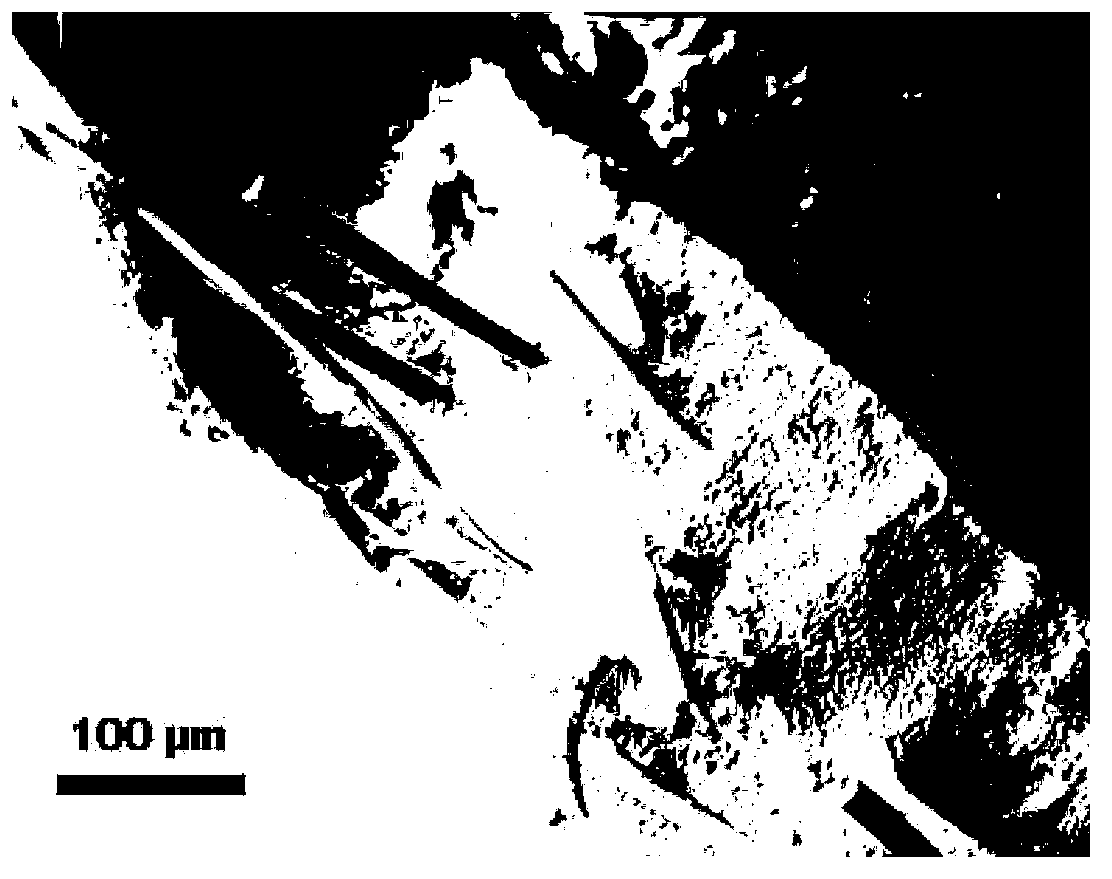

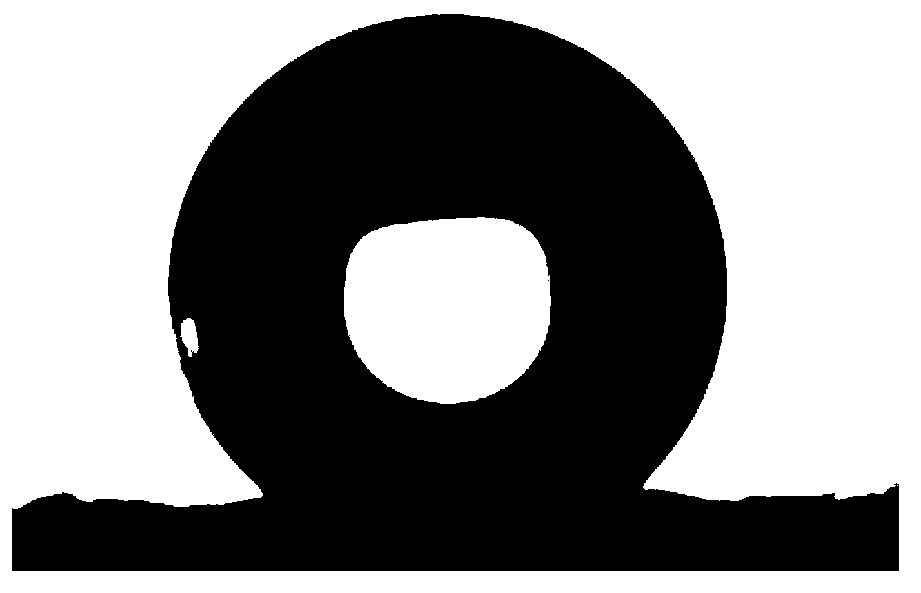

[0040] The oil-water separation material has a micro-nano composite porous struc...

Embodiment 2

[0044] Example 2, the preparation of a degradable oil-water separation omentum with a superhydrophobic and superlipophilic property with an addition ratio of 7.5%

[0045] (1) Dissolving PLA with a weight-average molecular weight of 69000 in 1,4-dioxane solvent is prepared into a solution with a concentration of 0.1g / mL, and added cut kapok short fibers (average length less than 3mm), The mass ratio of the kapok fiber to the PLA is 7.5%, and it is stirred to form a uniform mixture, and then the mixture is evenly spread on the glass substrate.

[0046] (2) Submerge the glass substrate coated with the solution in absolute ethanol for 30 minutes to perform phase separation to form a thin film.

[0047] (3) Take it out and put it into an oven to dry at 40° C. to obtain the superhydrophobic and superoleophilic biodegradable oil-water separation omentum.

[0048] The oil-water separation material has a micro-nano composite porous structure and kapok fibers are blended in the omentu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com