Five-shaft milling method for complex curved surface

A complex surface and milling technology, which is used in the milling of complex surface parts and the field of integral impeller parts, can solve the problems of inability to meet production, low cutting efficiency, and reduced milling efficiency, achieve good product quality, and ensure first-time success. efficiency, increase productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

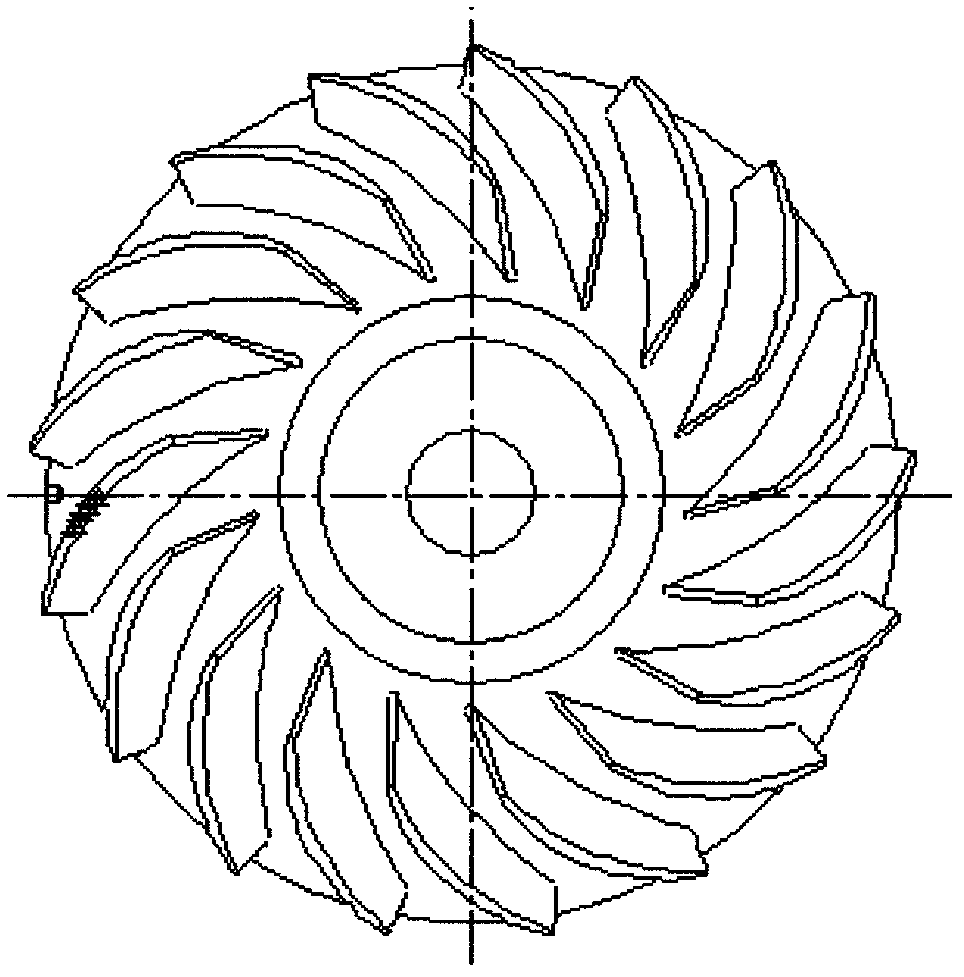

[0023] This embodiment is to process a high-performance integral impeller. The material of the integral impeller is 3A21, and the structure is as follows figure 1 As shown, the outlet diameter of the overall impeller is φ296mm, the inlet diameter of the impeller is φ195mm, the outlet blade height is 26mm, the inlet blade height is 40mm, the thinnest blade thickness is only 3mm, the minimum distance between adjacent blades is 19mm, and the number of blades distributed around the circumference is 17 pieces, because the material of this part is easy to generate large cutting heat and cutting vibration, which will cause the cutting tool to stick, and the tool is easily broken, causing deformation or damage to the curved surface of the blade and the runner, thus affecting the dynamic balance performance and quality of the overall part , using the complex curved surface five-axis milling method of the present invention to process, the specific implementation is as follows:

[0024] ...

Embodiment 2

[0031] This example is to process a high-performance integral impeller, the outlet diameter of the integral impeller is φ233mm, the impeller inlet diameter is φ160mm, the outlet blade height is 29mm, the inlet blade height is 70mm, the thinnest blade thickness is 0.9mm, and the minimum distance between adjacent blades is ≤6mm 13 blades are distributed around the circumference of the impeller. The total height of the impeller is 96mm. The complex curved surface is processed by the five-axis milling method, and the specific implementation is as follows:

[0032] 1: Selection of equipment Choose a five-axis machining center machine tool with good dynamics and stability;

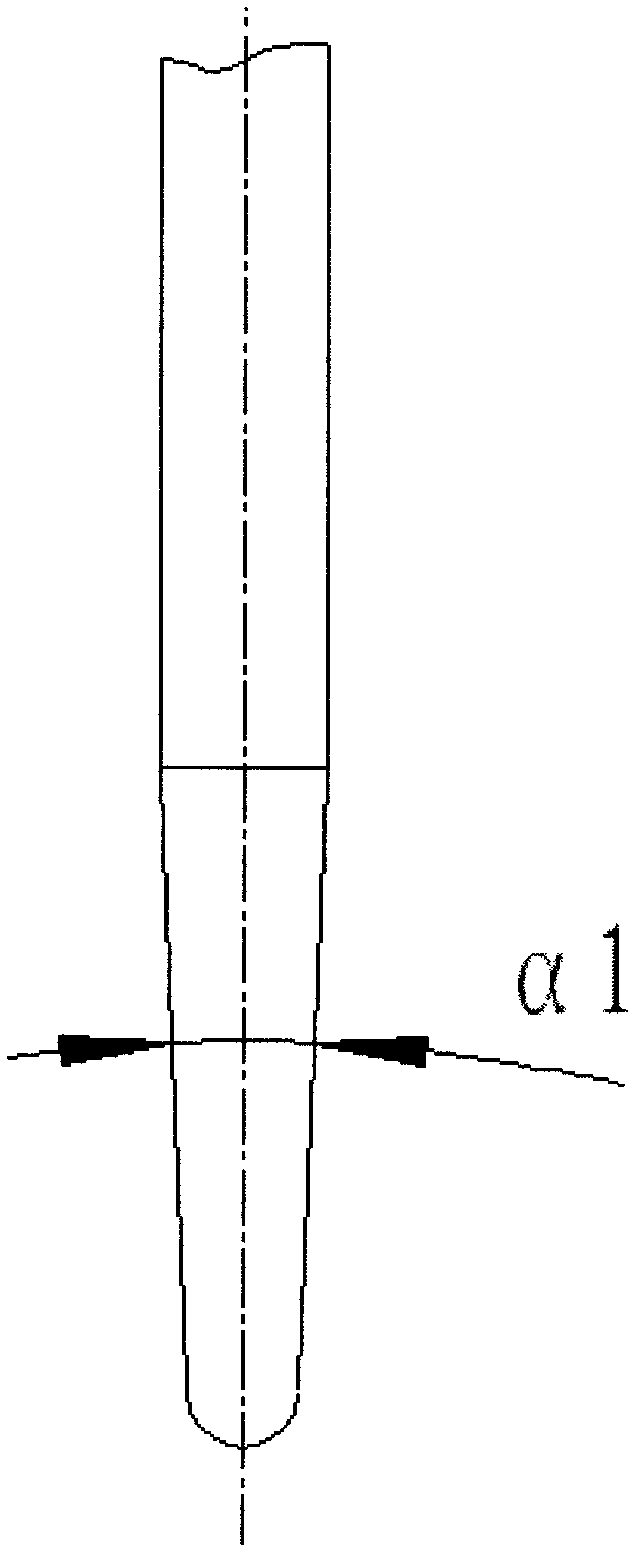

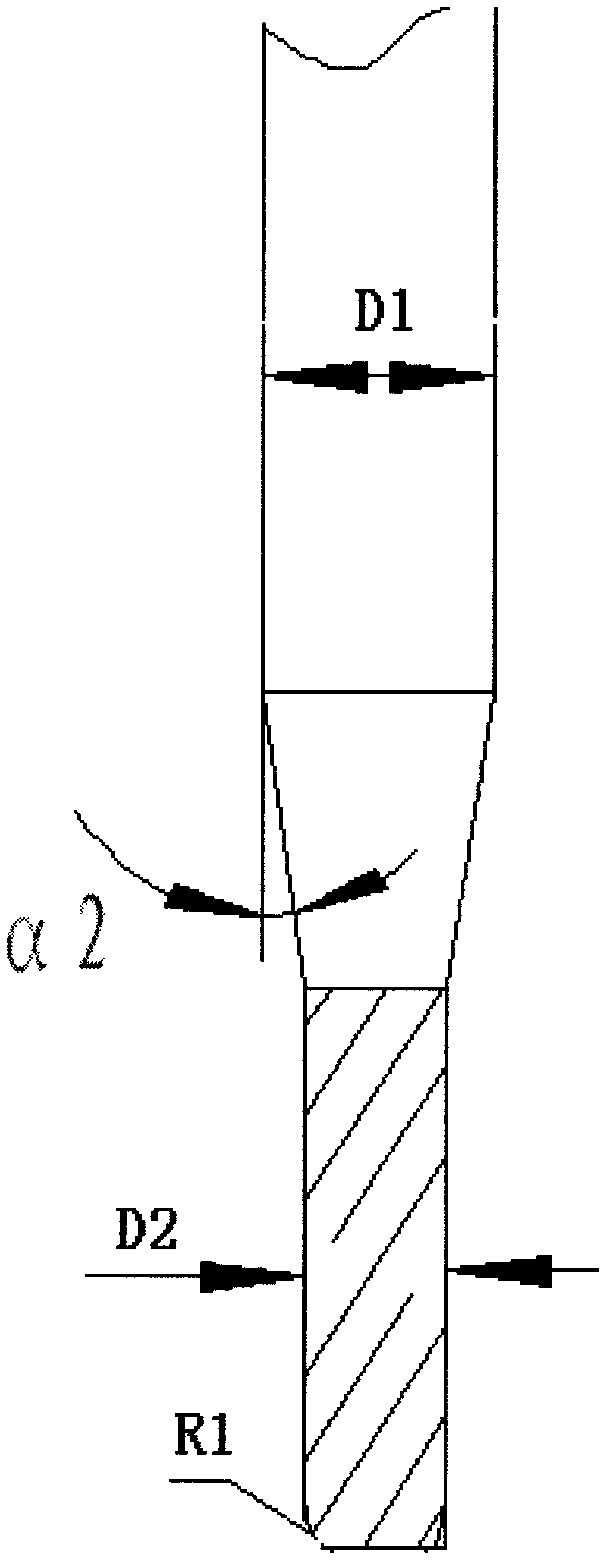

[0033] 2: The selection of the cutting tool is to choose the 0.4μm ultrafine particle uncoated carbide cutting tool, the tapered end mill with the cutting diameter D=φ3.5, the taper of the milling cutter α=5°, the length-to-diameter ratio of the cutting tool The number of cutter teeth Z=3 blades, the rounding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com