Lens cleaning solution and wet tissue

A cleaning liquid and lens technology, applied in glasses/protective glasses, glasses/goggles, optics, etc., can solve problems such as expensive, unclear, lens residue, etc., and achieve good anti-fog performance and good cleaning power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation process of lens cleaning solution:

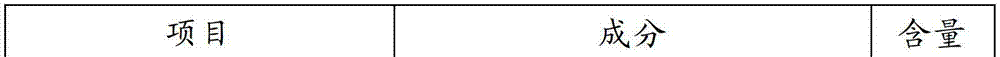

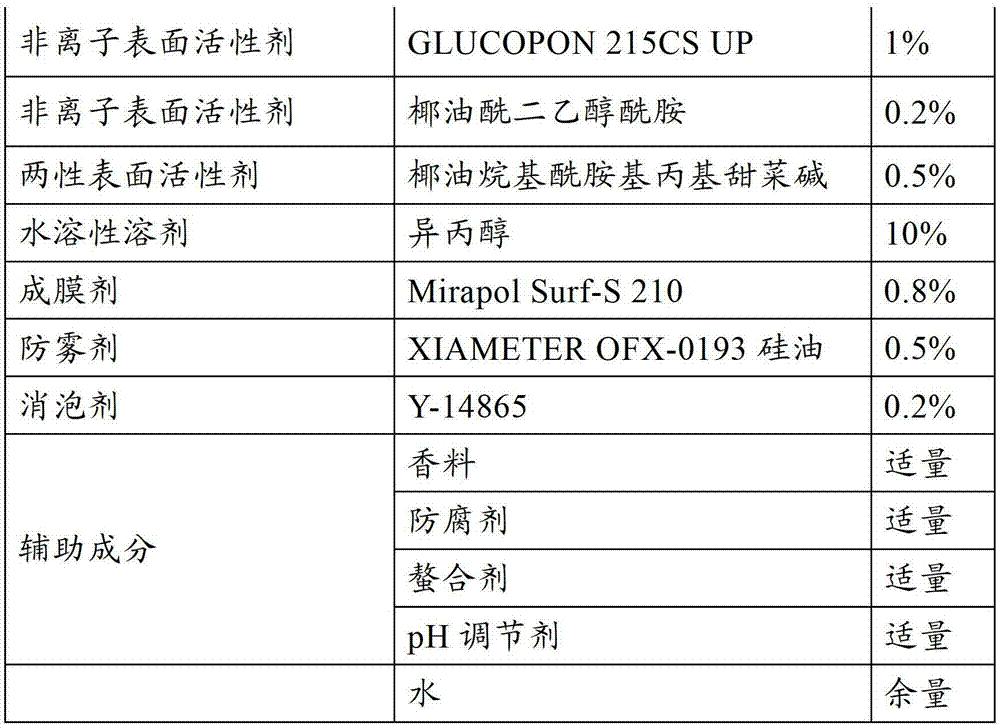

[0045] Add water to the mixing tank, add GLUCOPON215CS UP, Cocoyl Diethanolamide, Cocoalkylamidopropyl Betaine, Isopropanol, Mirapol Surf-S210, XIAMETEROFX-0193 Silicone Oil, Y-14865, Spices, After the preservative and chelating agent are mixed evenly, add an appropriate amount of pH regulator to adjust the pH value of the cleaning emulsion to 7-8. The specific addition ratio of each component is as follows:

[0046]

[0047]

[0048] Wipe making:

[0049] According to the mass ratio of 1.5:1, add the above-mentioned lens cleaning solution to the base material, and then cut it according to the actual required size to obtain the required wet wipes, wherein, the method of adding the lens cleaning solution to the base material includes dipping , spraying, etc.

Embodiment 2

[0051] Lens cleaning solution preparation process:

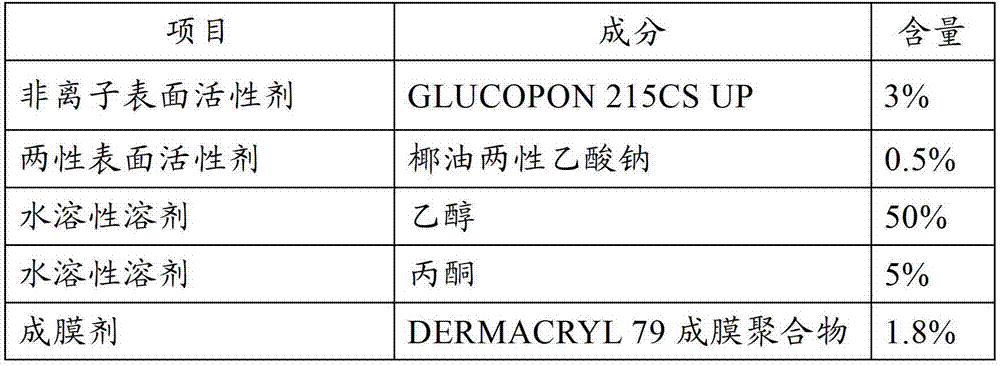

[0052] Add DERMACRYL79 film-forming polymer to ethanol and dissolve completely, then neutralize with triethanolamine, then add to water, then add GLUCOPON215CS UP, sodium cocoamphoacetate, acetone, nano silicon dioxide, Y-14865, preservatives, After the chelating agent and spices are stirred and mixed evenly, add an appropriate amount of pH regulator to adjust the pH value of the cleansing emulsion to 6.5-7.5. The specific addition ratio of each component is as follows:

[0053]

[0054]

[0055] Wipe making:

[0056] According to the mass ratio of 2.5:1, add the above-mentioned lens cleaning solution to the base material, and then cut it according to the actual required size to obtain the required wet wipes, wherein the method of adding the lens cleaning solution to the base material includes dipping , spraying, etc.

[0057] Compared with the prior art, the present invention selectively compound functional agents s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com