Single-side continuous hot zinc-plating method for composite strip steel

A composite strip and hot-dip galvanizing technology, which is applied in the hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problems of inability to realize large-scale production, impossibility of impact, scratching, poor bonding force of zinc layer, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

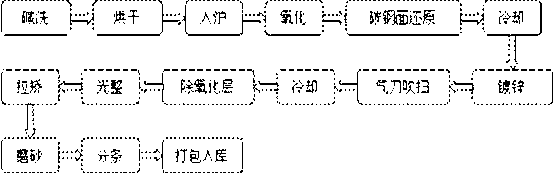

[0009] The present invention is described further below, and preferred embodiment of the present invention is: the single-sided continuous hot-dip galvanizing method of combined strip described in the present embodiment, and its technological process is:

[0010]

[0011] First of all, muffle furnaces are added in the gas preheating section and heating section. A certain amount of burners should be added in the preheating section so that the furnace temperature setting value in the heating section is around 1000~1200°C, which can realize rapid heating of the strip steel. In this section, soft water droplets are dripped into the furnace, or a certain amount of water vapor is introduced to increase the dew point in the muffle furnace to realize the oxidation of the composite strip, and the following reactions occur:

[0012] Fe+ FeO+

[0013] Cr+ +

[0014] At the design belt speed of 25~30m / min, when the strip runs to the heating section, the temperature shoul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com