Guide dust-eliminating device for drill hole

A guiding and dust-proof technology, applied to drill pipes, drill pipes, drilling equipment, etc., can solve problems such as environmental pollution, drill sticking, and potential safety hazards, and achieve the effects of avoiding damage, reducing maintenance costs, and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

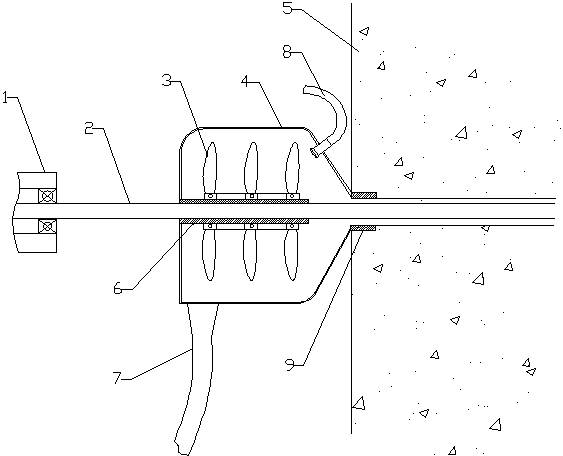

[0015] Specific embodiments: a drilling-guided dust removal device, comprising a dustproof outer cover 4 and a drill pipe 2, the drill pipe 2 penetrates the dustproof outer cover 4 in the axial direction, and a water spray head 8 is arranged inside the dustproof outer cover 4. The center of the dust cover 4 is slidingly socketed with the drill pipe 2 through the sliding sleeve 6; the sliding sleeve 6 is equipped with a multi-layer freely rotatable fan ring 3 through bearings; the supporting rotating bearings of the fan ring 3 are fixed together , the fan circles of each layer rotate synchronously. The bottom of the dust-proof outer cover 4 is provided with a slurry outlet 7, and the front end of the dust-proof outer cover 4 is funnel-shaped and is sealed and connected with the drilled hole. One end of the sliding sleeve 6 is fixedly connected with the rear end surface of the dustproof cover 4 . The dust-proof outer cover 4 is provided with an annular shaft sleeve 9 which can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com