A kind of preparation method of gate oxide layer

A technology of gate oxide layer and nitrous oxide, which is applied in the direction of semiconductor devices, can solve the problems of high reaction temperature, narrow application range, and fast reaction speed, and achieve the effect of increasing the process window and improving process adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

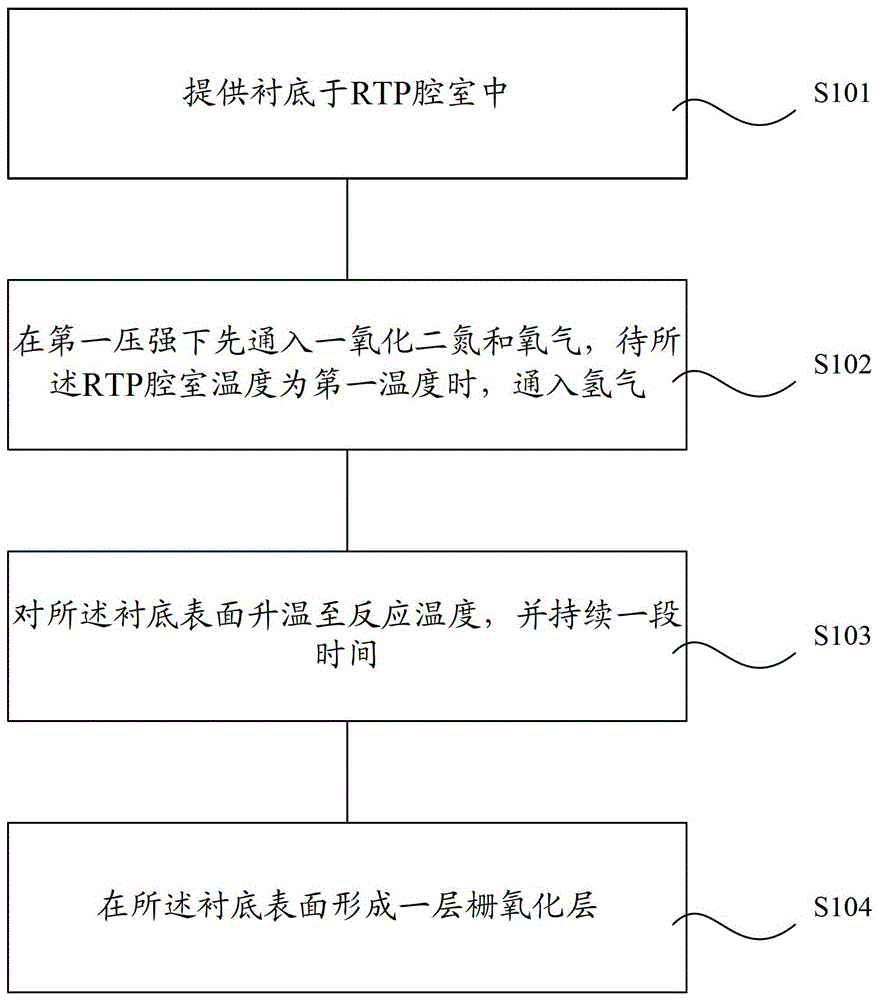

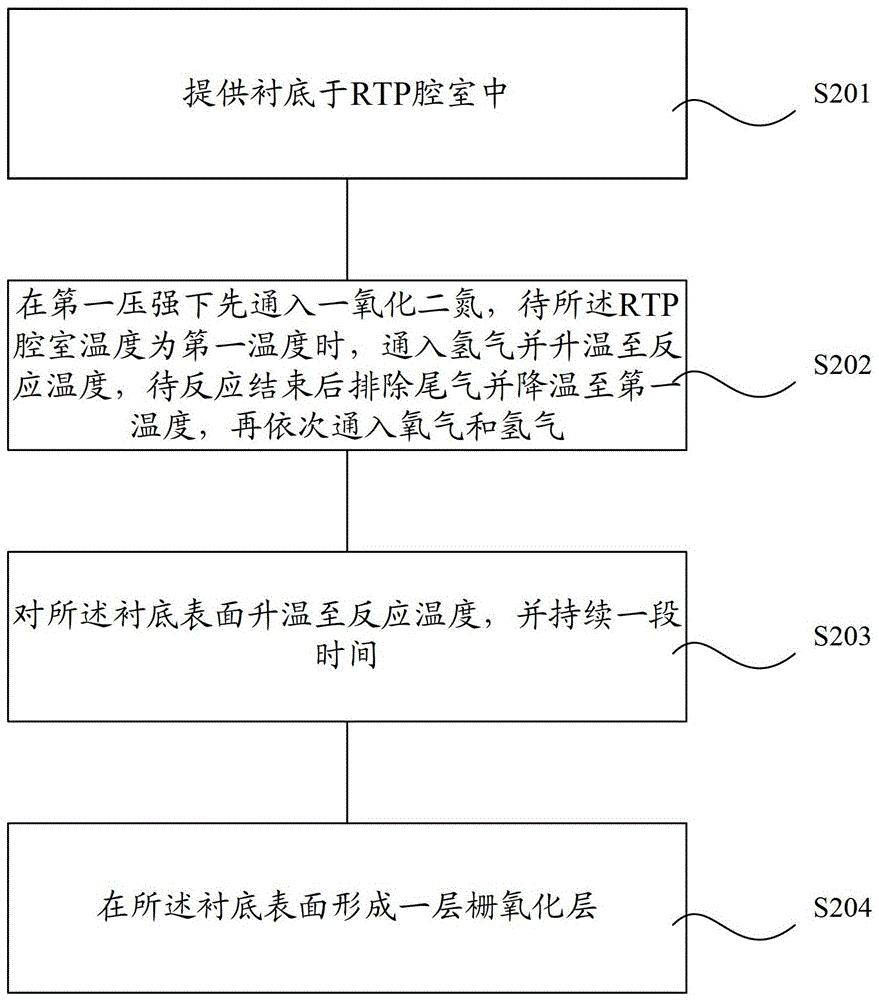

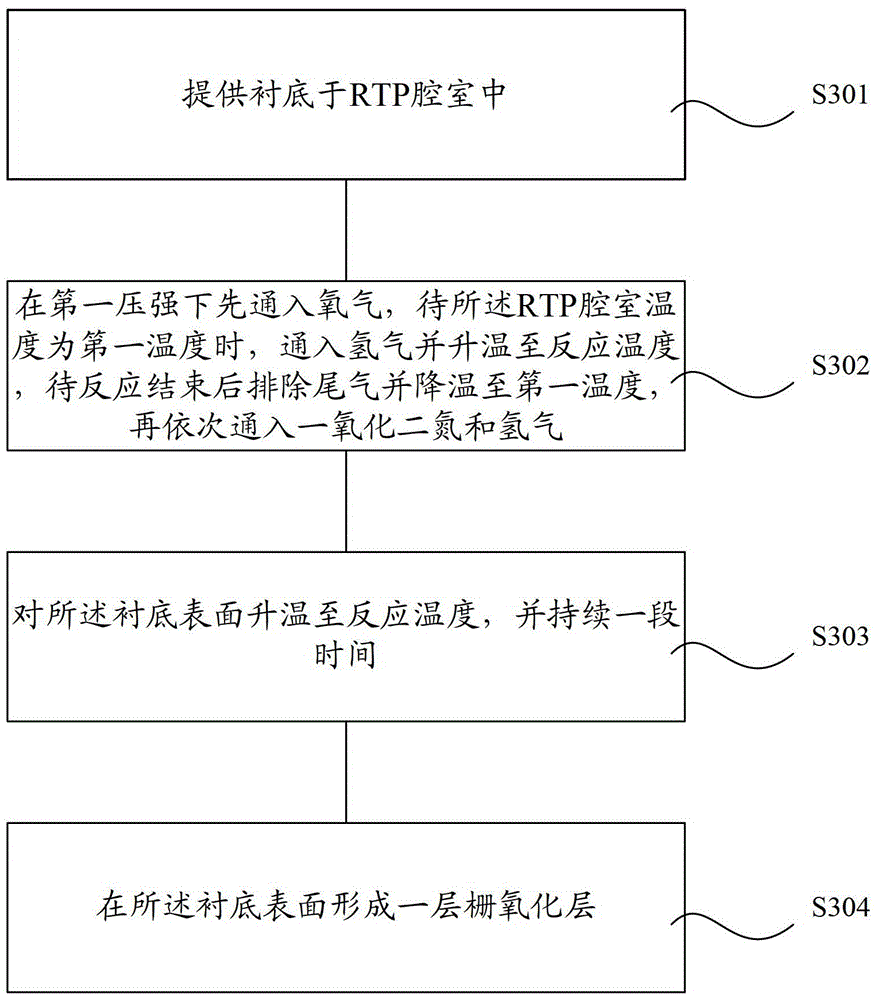

[0034] The preparation method of the gate oxide layer provided by the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form, and are only used for the purpose of conveniently and clearly assisting in describing the embodiments of the present invention.

[0035] The inventor found in long-term research that O 2 ISSG and N 2 The reaction of OISSG has its own characteristics, specifically, the difference is mainly due to the difference of the oxidizing agent. Then if the two oxidants are used simultaneously, the reaction conditions may be improved, which may meet the needs of producing ultra-thin gate oxide layers. Taking into account the explosive property of hydrogen, and the sequence of feeding oxygen and nitrous oxide, di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com