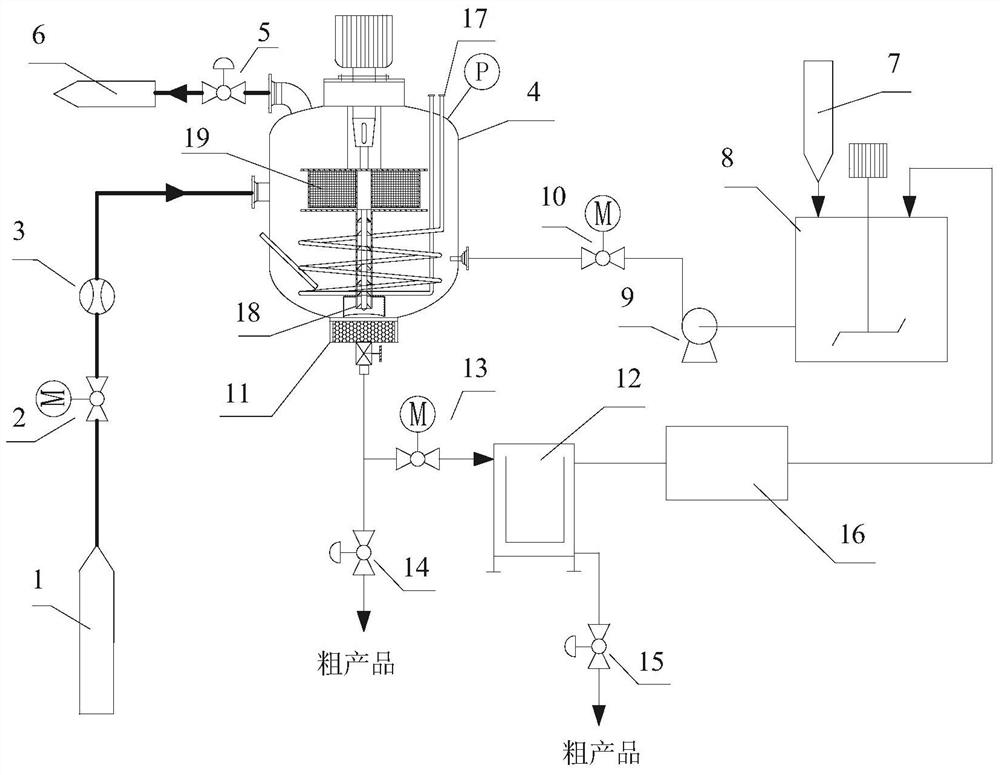

A kind of internal circulation supergravity heterogeneous catalytic hydrogenation device and its application

A hydrogenation device and heterogeneous catalysis technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems of uncontrollable hydrogenation reaction time, low operating pressure, and long process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Inner cycle high gravity heterogeneous catalysis for selective hydrogenation of cinnamaldehyde, the steps are as follows:

[0041] 1) 100mL cinnamic acid is added in the ethanol of 1L, then add the Pt-Ni alloy catalyst (the content of Pt in the described Pt-Ni alloy catalyst is 2wt% in the particle diameter of 2.0g is 50nm. Because Pt-Ni alloy catalyst is easy It is oxidized, so it needs to be reduced in hydrogen at 400°C for 2 hours before use), and after mixing uniformly in the premixing device, a suspension is obtained;

[0042] 2) Purge the internal circulation rotary packed bed with high-purity nitrogen at room temperature for 5 minutes, remove the air in the internal circulation rotary packed bed, and preheat at 130°C for 20 minutes, and pass the suspension obtained in step 1) into the internal circulation rotary packed bed After mixing for 1 hour, hydrogen gas was introduced, and the reaction was completed at a rotation speed of 2000 rpm, 3 MPa, and 90 ° C to obt...

Embodiment 2

[0049] The method for the hydrogenation of chloronitrobenzene with high gravity heterogeneous catalysis in internal circulation, the steps are as follows:

[0050] 1) Add 200ml of chloronitrobenzene to 2L of ethanol, then add 1.5g of Pt catalyst with a particle size of 20nm, and mix well in the premixing device to obtain a suspension;

[0051] 2) Purge the internal circulation rotary packed bed with high-purity nitrogen at room temperature for 5 minutes, remove the air in the internal circulation rotary packed bed, and preheat at 130°C for 20 minutes, and pass the suspension obtained in step 1) into the internal circulation rotary packed bed After 1 hour, hydrogen gas was introduced again, and the reaction was carried out at 1800 rpm, 2 MPa, and 120°C for 1 hour to obtain a liquid-solid mixture;

[0052] 3) After the liquid-solid mixture in step 2) is separated by the liquid-solid separation device at the bottom of the internal circulation rotating packed bed, the catalyst is ...

Embodiment 3

[0058] The method for the hydrogenation of cinnamaldehyde with high-gravity heterogeneous catalysis in internal circulation, the steps are as follows:

[0059] 1) Add 300mL of cinnamaldehyde to 3L of ethanol, then add 3.0g of Pt catalyst with a particle size of 20nm, mix evenly in a premixing device to obtain a suspension;

[0060] 2) Purge the internal circulation rotary packed bed with high-purity nitrogen at room temperature for 5 minutes, remove the air in the internal circulation rotary packed bed, and preheat at 110°C for 20 minutes, and pass the suspension obtained in step 1) into the internal circulation rotary packed bed for 1 hour After that, hydrogen gas was introduced again, and the reaction was carried out at 7 MPa and 110° C. for 1 hour at a rotational speed of 2000 rpm to obtain a liquid-solid mixture;

[0061] 3) After the liquid-solid mixture in step 2) is separated by the liquid-solid separation device at the bottom of the internal circulation rotating packed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com