Method for manufacturing brightness-improved GaN-based light emitting diode (LED) chip

A technology of LED chips and manufacturing methods, applied in the direction of electrical components, circuits, semiconductor devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

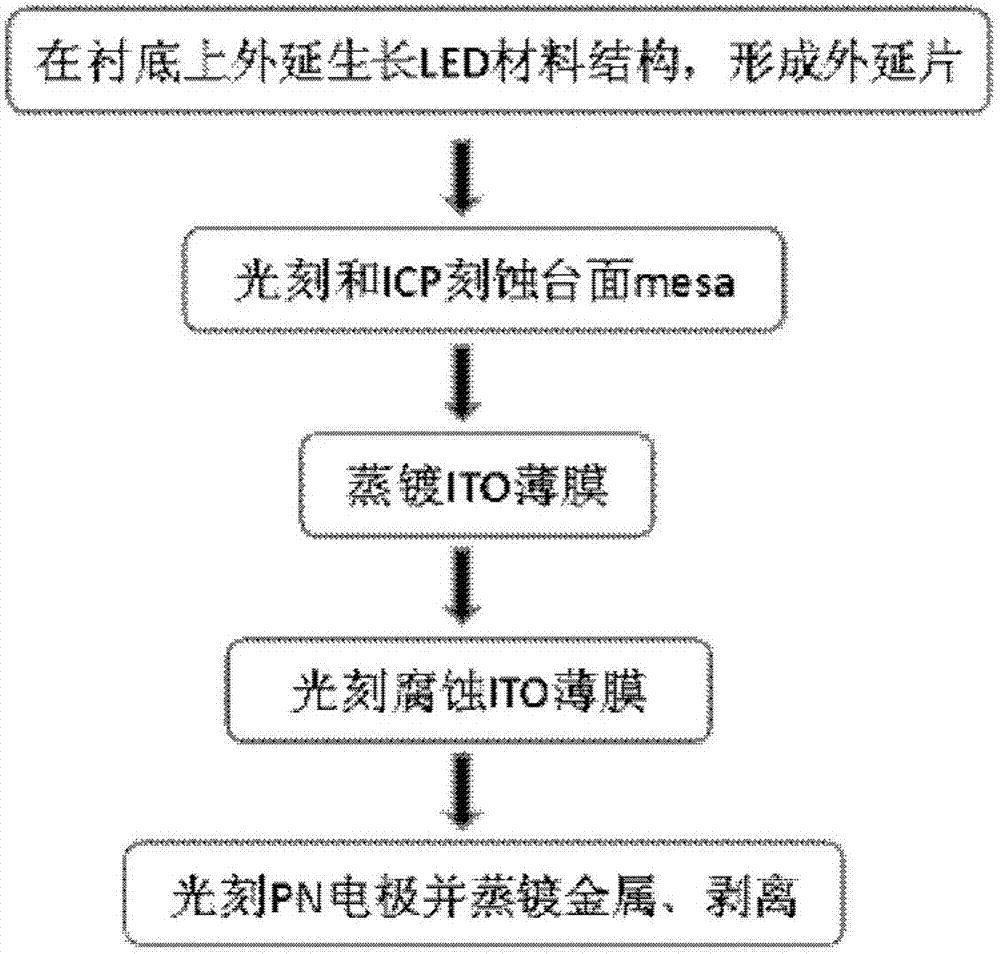

[0018] see figure 1 and figure 2 As shown, the present invention provides a method for manufacturing a GaN-based LED chip that improves brightness, comprising the steps of:

[0019] Step 1: Take a semiconductor substrate 1, the material of the semiconductor substrate 1 is sapphire, silicon, silicon carbide or metal;

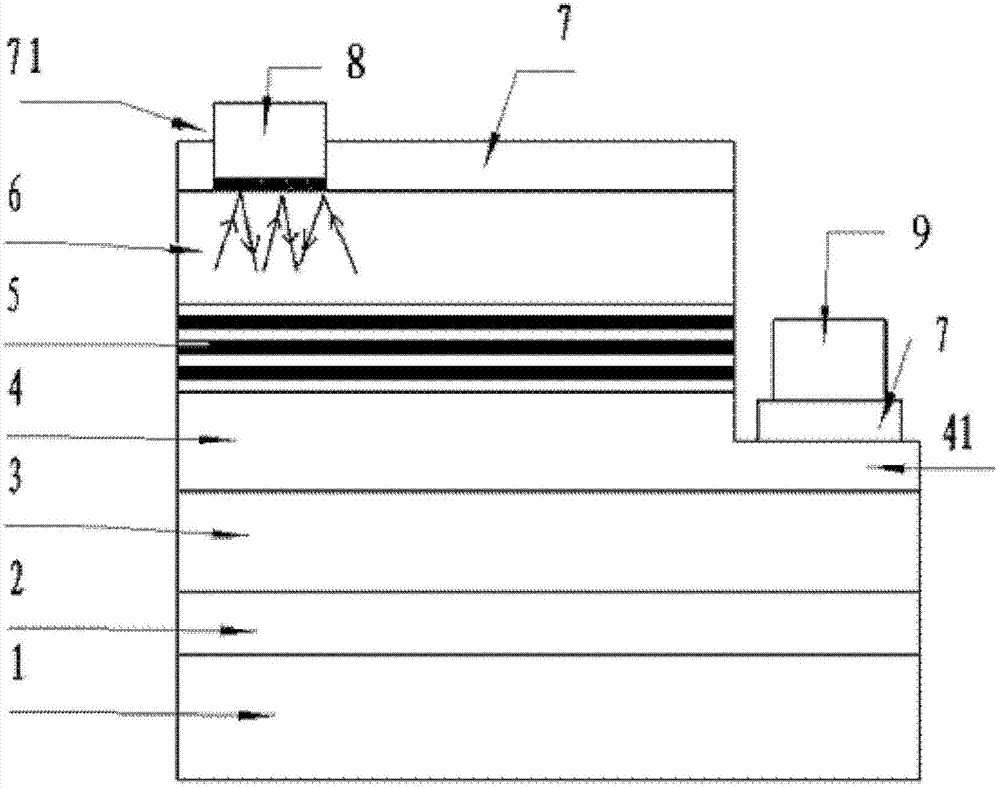

[0020] Step 2: Using metal-organic chemical vapor deposition (MOCVD), sequentially grow a low-temperature GaN buffer layer 2 (with a thickness of 1 μm), an undoped GaN layer 3 (with a thickness of 1 μm), and an N-GaN layer on the semiconductor substrate 1 4 (thickness is 3 μm), multi-quantum well light-emitting layer 5 (thickness is 150nm) and mP-GaN layer 6 (thickness is 300n), forms GaN epitaxial wafer, wherein said semiconductor substrate 1 is sapphire, silicon, silicon carbide or Metal;

[0021] Step 3: Etching downward on one side of the surface of the GaN epitaxial wafer, the etching depth reaches the N-GaN layer 4 , and forming a mesa 41 on one side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com